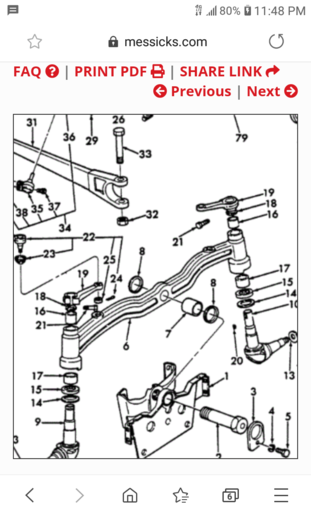

The later model 3400s had almost that

same exact axle. I had one that the

bushings were okay but the thrust

bearings were shot.

When I put new bearings in it I found the

same problem as you have.

What I did is brought both the spindle

and steering arm to a machine shop and

they cut a new keyway in the spindle and

broached a new keyway in the steering

arm. I think I had them do it about 60

degrees away from the original one but

it's been 15? years since I had it done

so ask their advice on the placement.

That is a special size woodroof key and

they did not have a milling cutter for

it. So we just milled a straight keyway

and used a 1/4" square key.

They were concerned about getting the

alignment of of the slot on the shaft and

slot on the arm exactly the same as

before but I told them a couple of

degrees one way or another can be

adjusted out with the tie rod adjustment.

I hung around and watched them do it and

both cuts together took about an hour so

it was not to costly to have done.

Looking at your upper spindle it appears

to be more worn than I thought. Can you

post better photos of it? You might ask

them about welding it up and turning it

back to standard as we talked about

before.