This message is a reply to an archived post by Destroked 450 on February 11, 2019 at 14:50:46.

The original subject was "Re: 1997 Ford New Holland 4630 192CI Turbo Diesel Overhaul".

As fate had it, what started out as a simple inframe turned into a

complete teardown to to broken rings, and all cylinders being way

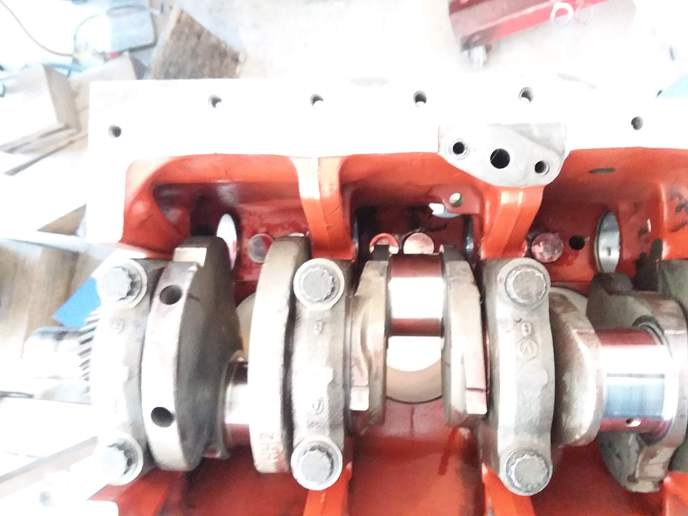

out of spec. Cam was fine, crank was fine.

The most puzzling thing was that it looked like someone was in this

engine recently. The crank had been turned to .20, bearings looked

more or less fine. Loads of black rtv on every mating surface made

clean up very difficult.

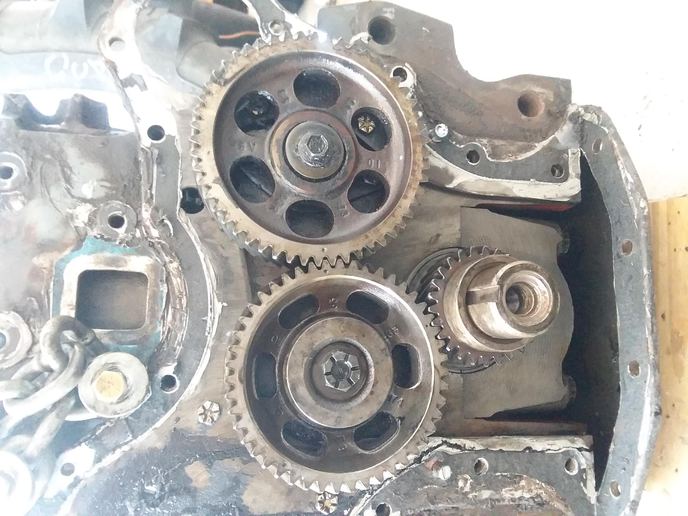

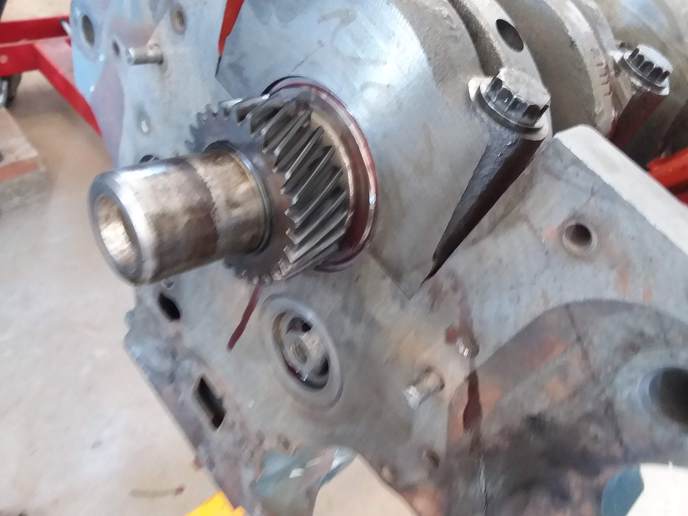

When I pulled the injection timing gear it was set to the 4 cylinder

mark instead of 3.

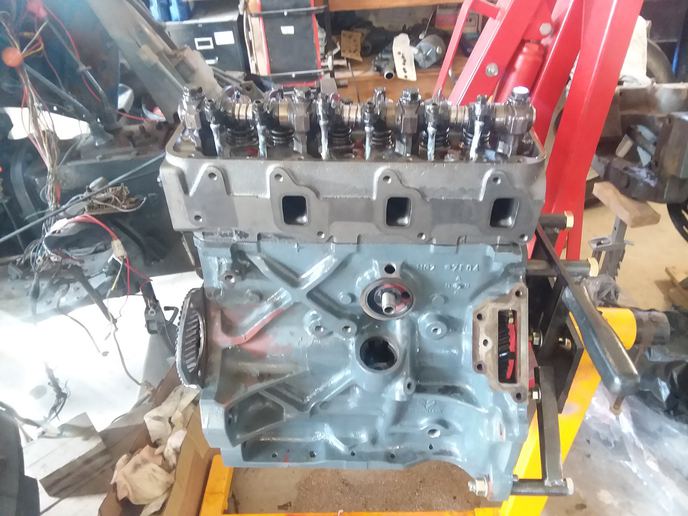

Needless to say the head and block were sent out. The block was

cleaned and sleeved. New pistons, rings and pins, new bearings all

around. New seals. New clutch disc. New oil pump. New oil and temp

senders with an added oil pressure gauge.

This all took some time due to schedules and down time at the shop,

but this week she is finally back together.

I will post better pics of the completed project soon.

The original subject was "Re: 1997 Ford New Holland 4630 192CI Turbo Diesel Overhaul".

As fate had it, what started out as a simple inframe turned into a

complete teardown to to broken rings, and all cylinders being way

out of spec. Cam was fine, crank was fine.

The most puzzling thing was that it looked like someone was in this

engine recently. The crank had been turned to .20, bearings looked

more or less fine. Loads of black rtv on every mating surface made

clean up very difficult.

When I pulled the injection timing gear it was set to the 4 cylinder

mark instead of 3.

Needless to say the head and block were sent out. The block was

cleaned and sleeved. New pistons, rings and pins, new bearings all

around. New seals. New clutch disc. New oil pump. New oil and temp

senders with an added oil pressure gauge.

This all took some time due to schedules and down time at the shop,

but this week she is finally back together.

I will post better pics of the completed project soon.