willjohnfrank

Member

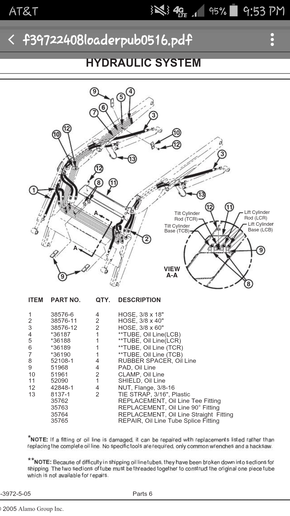

Hey guys I have a loader problem. I am

adding a rhino model 2408 loafer on a

Ford 3000 tractor. I am using the

hydraulic fluid coming from the adapter

block that they make for the fords. I

have a CGA5A4B1 Directional Control

Valve, Two Spool, 4 Way,?as pictured

below. Now when I bought the loader the

cylinders were very rusted and the owner

admitted never actually using them. He

bought it to add to his tractor. He said

they may need replacing. I have never

done this but I bought all of the

fittings needed and the valve and

everything except mounting the loafer to

the tractor. When I plugged everything

in and started the tractor only the

cylinders that raise the loader would

work and the oil was shooting out of

the cylinders. Excessively. Would that

amount of oil and air escape cause the

bucket not to function? My question is

once I buy 4 new cylinders will my

problem be fixed or did I have something

plugged in wrong? My loader has the 4

hoses separated into 2 groups. One

controlling the bucket and one going to

the arms. There are 4 hoses to connect

to my valve. Does it matter exactly

where they go on the valve? Thanks guys

adding a rhino model 2408 loafer on a

Ford 3000 tractor. I am using the

hydraulic fluid coming from the adapter

block that they make for the fords. I

have a CGA5A4B1 Directional Control

Valve, Two Spool, 4 Way,?as pictured

below. Now when I bought the loader the

cylinders were very rusted and the owner

admitted never actually using them. He

bought it to add to his tractor. He said

they may need replacing. I have never

done this but I bought all of the

fittings needed and the valve and

everything except mounting the loafer to

the tractor. When I plugged everything

in and started the tractor only the

cylinders that raise the loader would

work and the oil was shooting out of

the cylinders. Excessively. Would that

amount of oil and air escape cause the

bucket not to function? My question is

once I buy 4 new cylinders will my

problem be fixed or did I have something

plugged in wrong? My loader has the 4

hoses separated into 2 groups. One

controlling the bucket and one going to

the arms. There are 4 hoses to connect

to my valve. Does it matter exactly

where they go on the valve? Thanks guys