I have a 7710 Ford with an apl325 front axle. I am rebuilding the hubs with new bearings and seals. When I took the hub with the bearings in it off the spindle. Their was a thin brass looking shim that came out. I can not find it in the parts diagram. It does say under the seal info that you need to remove the wear sleeve from the shaft. Does anyone know what the wear sleeve is or what the thin brass shim might be?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter fordman81

- Start date

(quoted from post at 20:10:49 03/31/16) I have a 7710 Ford with an apl325 front axle. I am rebuilding the hubs with new bearings and seals. When I took the hub with the bearings in it off the spindle. Their was a thin brass looking shim that came out. I can not find it in the parts diagram. It does say under the seal info that you need to remove the wear sleeve from the shaft. Does anyone know what the wear sleeve is or what the thin brass shim might be?

Are you sure that is an APL325?? Are you REALLY sure? Check....

Looks like a 345 to me.

Not saying I'm not wrong, but check.

I think that is the wear liner you have there. They no longer use the wear liner. For a good long time now they've used the two piece

cassette seal. Installation of that seal requires removal of the weal liner, a complete stripping of the spindle surface with ether, then

soapy water. If you don't, the seal won't adhere to the spindle and it will leak...

Suggestion: acquire the original Ford Dxnn type part numbers from the part system and then check with A&I dealers or google the numbers.

You'll be pleasantly surprised compared to the pricing the mafia offers on the same parts. Fawcett Tractor is also another excellent

supplier of ZF parts as they have their own sources at good prices.

Rod

Looks like a 345 to me.

Not saying I'm not wrong, but check.

I think that is the wear liner you have there. They no longer use the wear liner. For a good long time now they've used the two piece

cassette seal. Installation of that seal requires removal of the weal liner, a complete stripping of the spindle surface with ether, then

soapy water. If you don't, the seal won't adhere to the spindle and it will leak...

Suggestion: acquire the original Ford Dxnn type part numbers from the part system and then check with A&I dealers or google the numbers.

You'll be pleasantly surprised compared to the pricing the mafia offers on the same parts. Fawcett Tractor is also another excellent

supplier of ZF parts as they have their own sources at good prices.

Rod

The tag says apl 325. From the New Holland diagrams the 345 has one single nut that holds the planetary gear on. I was planning on cleaning it with a wire brush on an angle grinder. Never heard of ether but hey I think it's cheaper than brake cleaner anyway and a little soap and water never hurt anything. I'll chuck that wear ring in the scrap and get it cleaned up. I ordered my parts from http://www.malpasonline.co.uk/ cheapest place I could find going to do both sides at the same time.

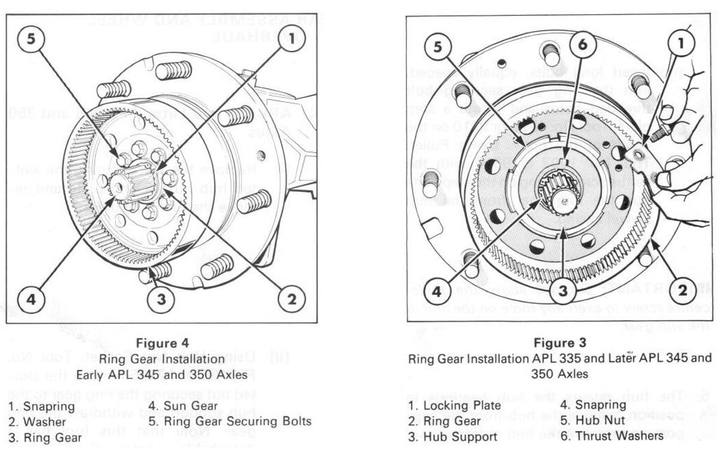

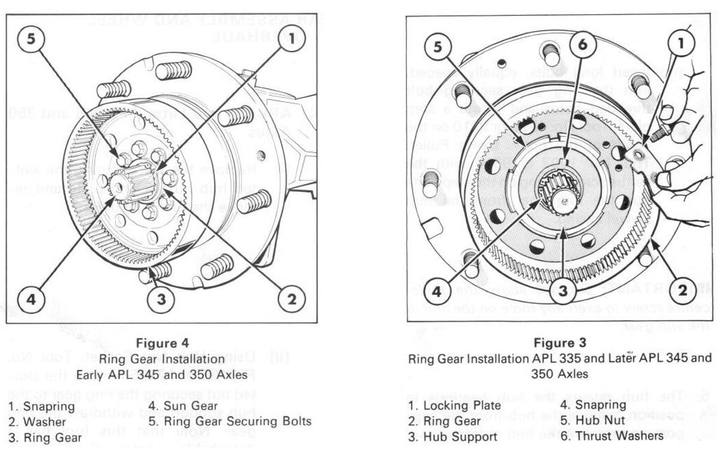

I can assure you that the 345 ring gear is retained exactly as yours is in your pics. I am fairly certain that the 325 was the one retained

by the single nut.... My 7710 is a 4/85 and it has the 345 axle. I think the earlier ones may have had the 325 and later ones had a Carraro.

The reason for using ether or soapy water to clean it is to strip the oil off the spindle so the inner rubber ring of the seal adheres to the

spindle as it must not turn. These seals adhere to both the spindle and the hub with the wear surface being inside the cassette seal. If it

doesn't adhere it will leak and wear the spindle.

Now I'm actually starting to wonder what you have for hubs on that thing. I'll try and look in the parts book later on today.

Rod

by the single nut.... My 7710 is a 4/85 and it has the 345 axle. I think the earlier ones may have had the 325 and later ones had a Carraro.

The reason for using ether or soapy water to clean it is to strip the oil off the spindle so the inner rubber ring of the seal adheres to the

spindle as it must not turn. These seals adhere to both the spindle and the hub with the wear surface being inside the cassette seal. If it

doesn't adhere it will leak and wear the spindle.

Now I'm actually starting to wonder what you have for hubs on that thing. I'll try and look in the parts book later on today.

Rod

Bern

Well-known Member

- Location

- Mount Vernon, WA

I can tell you exactly what's going on here, and this will be no April fools joke.

First off, you really do have an APL325 axle. According to the NH parts catalog, these axles were installed on 7710s from Jan 1981 to April 1984. These axles had no provision for wheel bearing preload. The preload was designed and machined in from the factory at ZF, and you simply bolted the parts together and that was that. Later axles such as the APL345 used an adjustable nut, much like a conventional wheel bearing fastener, to adjust bearing preload.

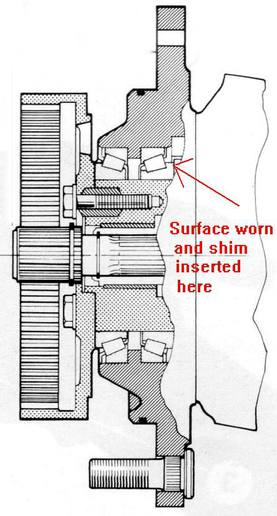

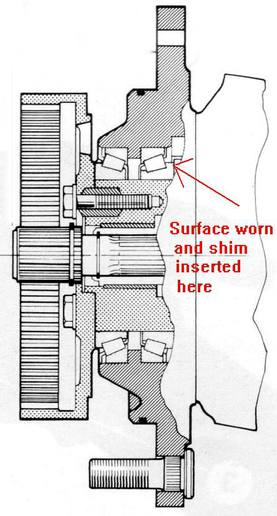

The shim you see in the picture is very easily explained. At some point in the past (remember, this thing is over 30 years old) it would appear that the old wheel bearings went out and wore the back bearing locating surface on the spindle (you can spot this if you look at the pictures closely). This resulted in end play of the wheel hub instead of the desired preload. Rather than spend big dollars for a new spindle, the person who put it together simply took a brass shim and used it as a spacer to make up for the wear on the spindle. This is why you don't see it in the parts book.

I would put the same shim back in and make sure you have the desired rolling torque that the repair manual calls for. If you have too little, you need more shims. Too much rolling torque will require less shims. This will be a fairly critical adjustment that you should perform carefully.

The seal surface is a whole 'nother story. Let me know if you need info on that.

One last thing: make sure the dowels that held the ring gear on are solid and not split. The original ones were split, and they had issues with them coming loose and absolutely destroying everything inside.

First off, you really do have an APL325 axle. According to the NH parts catalog, these axles were installed on 7710s from Jan 1981 to April 1984. These axles had no provision for wheel bearing preload. The preload was designed and machined in from the factory at ZF, and you simply bolted the parts together and that was that. Later axles such as the APL345 used an adjustable nut, much like a conventional wheel bearing fastener, to adjust bearing preload.

The shim you see in the picture is very easily explained. At some point in the past (remember, this thing is over 30 years old) it would appear that the old wheel bearings went out and wore the back bearing locating surface on the spindle (you can spot this if you look at the pictures closely). This resulted in end play of the wheel hub instead of the desired preload. Rather than spend big dollars for a new spindle, the person who put it together simply took a brass shim and used it as a spacer to make up for the wear on the spindle. This is why you don't see it in the parts book.

I would put the same shim back in and make sure you have the desired rolling torque that the repair manual calls for. If you have too little, you need more shims. Too much rolling torque will require less shims. This will be a fairly critical adjustment that you should perform carefully.

The seal surface is a whole 'nother story. Let me know if you need info on that.

One last thing: make sure the dowels that held the ring gear on are solid and not split. The original ones were split, and they had issues with them coming loose and absolutely destroying everything inside.

Bern

Well-known Member

- Location

- Mount Vernon, WA

Never mind on the dowels. I took another look and I see that they are solid. Gotta love the edit feature on this website...

I will add that there is evidence of a major wheel bearing failure in the past. The backside of the hub was clearly rubbing on the spindle.

I will add that there is evidence of a major wheel bearing failure in the past. The backside of the hub was clearly rubbing on the spindle.

Bern

Well-known Member

- Location

- Mount Vernon, WA

Rod,

I often get my ZF axle parts from Deere. The last time I bought a hub seal for an APL345 on a 7610, it was $25 from Deere and $140 from NH. It was a 2950 or 2955 JD that I used as a model number. I refuse to pay NH's mafia prices.

I often get my ZF axle parts from Deere. The last time I bought a hub seal for an APL345 on a 7610, it was $25 from Deere and $140 from NH. It was a 2950 or 2955 JD that I used as a model number. I refuse to pay NH's mafia prices.

Bern

Well-known Member

- Location

- Mount Vernon, WA

Rod, sorry but it's the other way around. The 345 uses the adjustable single nut, and the 325 is bolted together with the 8 bolts. Parts and service manuals will confirm this.

Axle usage on the 10 series is roughly as follows:

APL 325 from 1981 to 1984

APL 345 from 1984 to 1987

Carraro from 1987 onwards

Of the 3, the APL 345 is my favorite. It's much heavier than the 325, and I despise the king pin bearing setup on the Carraros.

Axle usage on the 10 series is roughly as follows:

APL 325 from 1981 to 1984

APL 345 from 1984 to 1987

Carraro from 1987 onwards

Of the 3, the APL 345 is my favorite. It's much heavier than the 325, and I despise the king pin bearing setup on the Carraros.

(quoted from post at 07:08:20 04/01/16) I can tell you exactly what's going on here, and this will be no April fools joke.

First off, you really do have an APL325 axle. According to the NH parts catalog, these axles were installed on 7710s from Jan 1981 to April 1984. These axles had no provision for wheel bearing preload. The preload was designed and machined in from the factory at ZF, and you simply bolted the parts together and that was that. Later axles such as the APL345 used an adjustable nut, much like a conventional wheel bearing fastener, to adjust bearing preload.

The shim you see in the picture is very easily explained. At some point in the past (remember, this thing is over 30 years old) it would appear that the old wheel bearings went out and wore the back bearing locating surface on the spindle (you can spot this if you look at the pictures closely). This resulted in end play of the wheel hub instead of the desired preload. Rather than spend big dollars for a new spindle, the person who put it together simply took a brass shim and used it as a spacer to make up for the wear on the spindle. This is why you don't see it in the parts book.

I would put the same shim back in and make sure you have the desired rolling torque that the repair manual calls for. If you have too little, you need more shims. Too much rolling torque will require less shims. This will be a fairly critical adjustment that you should perform carefully.

The seal surface is a whole 'nother story. Let me know if you need info on that.

One last thing: make sure the dowels that held the ring gear on are solid and not split. The original ones were split, and they had issues with them coming loose and absolutely destroying everything inside.

Well the dowels are solid and the shim does look like it came out from under the bearing. Would you reuse the shim or try to have the spindle fix at a machine shop? Whats the story on the seal surface?

Bern

Well-known Member

- Location

- Mount Vernon, WA

Spindle fix at a machine shop will be big dollars - they'd have to somehow build up that worn surface and then turn it down. Then you'd also have to try and find a print spec so they had something to go off of, or else disassemble the other side for measurements (assuming it's good). For all that hassle and expense, I'd shim it.

The seal surface issue can be tricky. Original seals were one piece that fit right onto the spindle, like old style wheel bearings had. Then they came out with a two piece design that incorporated a separate wear sleeve. The seal itself looked the same as the first style, but had a larger inside diameter to allow for the wear sleeve.

The latest design is a "unitized" style similar to what HD trucks have been using for years. It appears to be one piece, but if you look close, the ID can be rotated relative to the OD. This is a superior design, however if your spindle has a wear sleeve on it, it MUST be removed, or else you'll destroy the new seal.

Complicating the whole mess is that the aftermarket parts system might supply any of the 3 types listed above. You have to be aware of the differences when you buy a seal. I believe if you buy a seal from NH (big $$), you'll get the latest unitized design, which again, requires you to remove the wear sleeve.

The seal surface issue can be tricky. Original seals were one piece that fit right onto the spindle, like old style wheel bearings had. Then they came out with a two piece design that incorporated a separate wear sleeve. The seal itself looked the same as the first style, but had a larger inside diameter to allow for the wear sleeve.

The latest design is a "unitized" style similar to what HD trucks have been using for years. It appears to be one piece, but if you look close, the ID can be rotated relative to the OD. This is a superior design, however if your spindle has a wear sleeve on it, it MUST be removed, or else you'll destroy the new seal.

Complicating the whole mess is that the aftermarket parts system might supply any of the 3 types listed above. You have to be aware of the differences when you buy a seal. I believe if you buy a seal from NH (big $$), you'll get the latest unitized design, which again, requires you to remove the wear sleeve.

The last part I bought.... the Deere mainline seal was about half of the mafia price.... but the same seal with the same part number in the same bag through the A&I system was about 20 bucks which was again about 1/4 what Deere's mainline price was.

On hard parts you really need to get in touch with Fawcetts because they have their own supply of good quality parts for ZF that will compare to the cheapest internet prices you will find and they will have 90% of what you need on the shelf, ready to go.

Rod

On hard parts you really need to get in touch with Fawcetts because they have their own supply of good quality parts for ZF that will compare to the cheapest internet prices you will find and they will have 90% of what you need on the shelf, ready to go.

Rod

I can not remember if mine is a 345 or 350.... what I can tell you is the tractor is a round roof 7710, Romeo build date, 4/30/85 and according to the parts book it should have a 345/350. It does not have the single retaining nut, but the 8 bolt compression ring gear. The parts book obviously does not reflect this fact today.... but it seems to me that it did a year ago because somehow or other I did get the right parts.... everything from planets, seals, bearings and a carrier for one and ring for the other.

Rod

Rod

Bern

Well-known Member

- Location

- Mount Vernon, WA

Mystery solved...

Bern

Well-known Member

- Location

- Mount Vernon, WA

This picture will help you understand what you're doing with the shim.

Similar threads

- Replies

- 2

- Views

- 211

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy