Hobo,NC

Well-known Member

- Location

- Sanford, NC

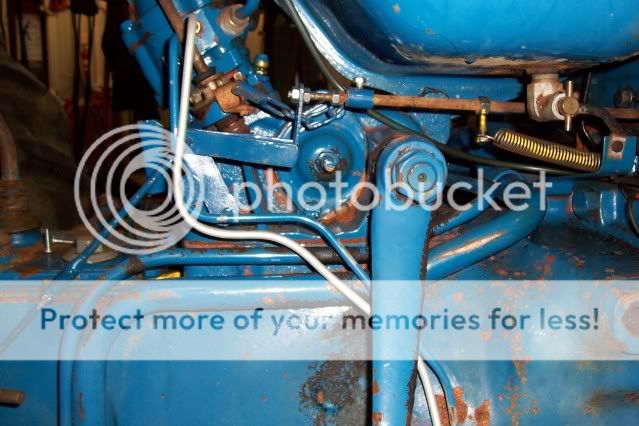

Been planing on clutching and doing some other maintenance for a year,,, planed completion date Feb 1 2010,,, did not start till Feb 2 2010,,, took Feb 3 2010 off to go to the southern farm show.

8) Ran into a problem I ordered a 15 spline clutch kit so to save on return ship'n I ordered a 10 spline main drive disc,,, gonna return the 15 spline,,,

I did not have a clutch line up too for a 10 spline (15 spline does not work on a 10 spline so I made one out of steel (took a slow learner 2 1/2 hours) the more I thought about it I could have turned the the 15 spline down to work but I never liked the plastic tool to begin with,,, I read the manual and it stated if a if a button clutch was to be installed the long hub protrusion must face the flywheel (it had a button clutch),,, if a organic lined disc is to be used the long hub must face the double clutch,,, I used the organic so installed the long part of the hub to the DC,,, I measured it all out and could not see were it would make a difference :roll: Clutch job went OK...

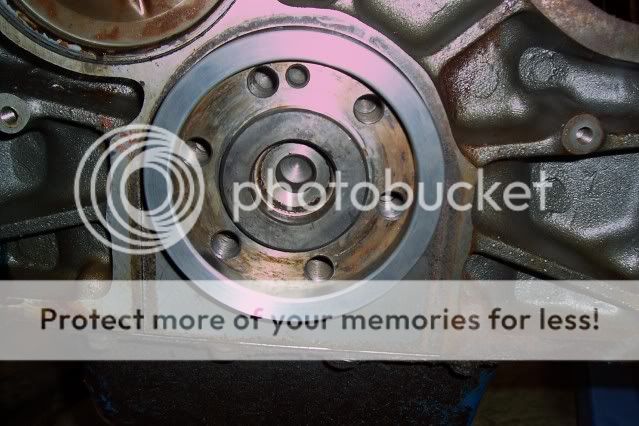

While I was their I replaced the rear crank seal,,, I first made a tool out of a PVC conector,,, then found a piece of steel i could turn out and add a step so not to install the seal to deep and made a plate to run the installer in,,, worked good,,, took 2 hour's are so to make it...

I also replaced the front axle pin and bushing,,, the pin fought me the hole dang way,,, what a beach to remove,,, took lots of heat,,, I had no problem installing the new pin go figger... this 3000 has a 1 3/4" axle pin and a 2" center axle pin bushing,,, it has a spacer to make up the difference,,, while I had a mess on the lathe turned out a new spacer,,, BYW the spacer sells for $73 from CNH,,, add another hour to the job,,, before I paid $73 I would reuse the old spacer... I also made a remover to knock out the old bushing and boarded a washer to fit the remover to convert it to a installer...

engine bolted up,,, axle installed,,, added a new water pump and hoses,,, installed the new radiator,,, aftermarket Radiator fits nice just had to tap for the shroud screws... installed tin and added a new muffler..

got a few questions

1) could not get the hydraulic tube suction to pull out of the rear housing so let it along,,, how does that bugger come out... was gonna replace the o-ring,,, soon I am going to remove the lift cover and will take a look then

2) Haft way tightened the new muffler on the manifold pipe (vertical) with a standard muffler clamp,,, would like to have a nice band clamp instead of a ugly muff clamp right were I can see it,,, mite have to make it :idea:

Next I need to rebuild the loader frame,,, pull the lift cover and change out the fluids,,, I had all new bolts on hand for the axle rebuild,,, it needed them bad,,, a loader sure works on'em :wink: here's a few pix...

[/img]

[/img]

[/img]

8) Ran into a problem I ordered a 15 spline clutch kit so to save on return ship'n I ordered a 10 spline main drive disc,,, gonna return the 15 spline,,,

I did not have a clutch line up too for a 10 spline (15 spline does not work on a 10 spline so I made one out of steel (took a slow learner 2 1/2 hours) the more I thought about it I could have turned the the 15 spline down to work but I never liked the plastic tool to begin with,,, I read the manual and it stated if a if a button clutch was to be installed the long hub protrusion must face the flywheel (it had a button clutch),,, if a organic lined disc is to be used the long hub must face the double clutch,,, I used the organic so installed the long part of the hub to the DC,,, I measured it all out and could not see were it would make a difference :roll: Clutch job went OK...

While I was their I replaced the rear crank seal,,, I first made a tool out of a PVC conector,,, then found a piece of steel i could turn out and add a step so not to install the seal to deep and made a plate to run the installer in,,, worked good,,, took 2 hour's are so to make it...

I also replaced the front axle pin and bushing,,, the pin fought me the hole dang way,,, what a beach to remove,,, took lots of heat,,, I had no problem installing the new pin go figger... this 3000 has a 1 3/4" axle pin and a 2" center axle pin bushing,,, it has a spacer to make up the difference,,, while I had a mess on the lathe turned out a new spacer,,, BYW the spacer sells for $73 from CNH,,, add another hour to the job,,, before I paid $73 I would reuse the old spacer... I also made a remover to knock out the old bushing and boarded a washer to fit the remover to convert it to a installer...

engine bolted up,,, axle installed,,, added a new water pump and hoses,,, installed the new radiator,,, aftermarket Radiator fits nice just had to tap for the shroud screws... installed tin and added a new muffler..

got a few questions

1) could not get the hydraulic tube suction to pull out of the rear housing so let it along,,, how does that bugger come out... was gonna replace the o-ring,,, soon I am going to remove the lift cover and will take a look then

2) Haft way tightened the new muffler on the manifold pipe (vertical) with a standard muffler clamp,,, would like to have a nice band clamp instead of a ugly muff clamp right were I can see it,,, mite have to make it :idea:

Next I need to rebuild the loader frame,,, pull the lift cover and change out the fluids,,, I had all new bolts on hand for the axle rebuild,,, it needed them bad,,, a loader sure works on'em :wink: here's a few pix...

[/img]