Hi all.

Been a while since ive been on here.

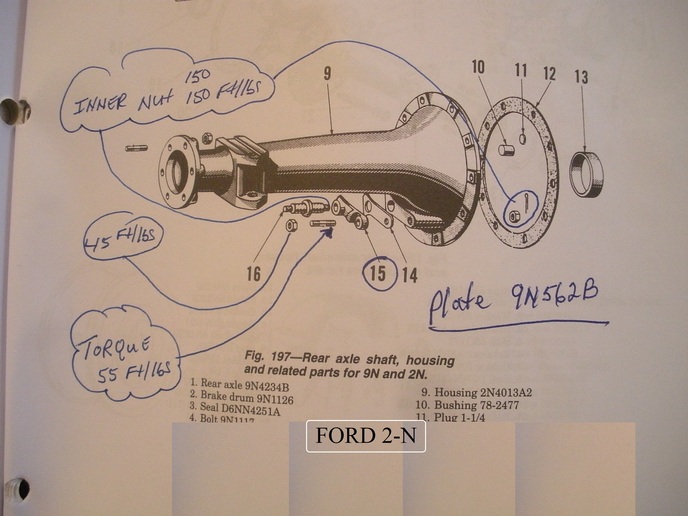

I am looking for info on removing the RHS axle trumpet to fix/tighten the lower link shaft pins.

Found this post in the archives which explains it all.

https://www.yesterdaystractors.com/cgi-bin/viewit.cgi?bd=ferg&th=34965

I am looking for the helpful info sheet that John (UK) emailed to users. If anyone has one for the axle pin fix please contact me.

Mine is a tea20 oe te20.

Cheers

Been a while since ive been on here.

I am looking for info on removing the RHS axle trumpet to fix/tighten the lower link shaft pins.

Found this post in the archives which explains it all.

https://www.yesterdaystractors.com/cgi-bin/viewit.cgi?bd=ferg&th=34965

I am looking for the helpful info sheet that John (UK) emailed to users. If anyone has one for the axle pin fix please contact me.

Mine is a tea20 oe te20.

Cheers