Wosn_Fergie

New User

Hello everyone,

I recently got my hands on, at least what I think is, a Ferguson rarity. Although there is very little information available for the TEK variation, it is clear that it is mechanically identical to the later model TEAs. Finding any information about Frech built models is a challange in itself, but the serial plate is somewhat helpful. The color appears to be originally entirely red, but was repainted sometime in the past. I am looking for any and all information available regarding the TEKs. I hope some of you more experienced fellows can help me find out more.

The TEK itself is in very good condition and runs reasonably well. I suppose I will be constantly asking for your extensive knowledge and searching the forum for tips in the coming months. Although I will not be starting right away, I do want to make a plan. So, I do have a few questions for our more expereinced forum dwellers:

-Considering the TEK starts without issue and runs well, should I even be considering tearing the motor apart because of cleaning/servicing? Or would this just create more problems that it would solve?

-The trottle is sluggish and responds poorly. That would generally mean the carb is due for a teardown, correct?

-What is the RPM range for the TEA petrol motor? The TEK idles at 900/1000 RPM and only is reaching a RPM of 1900/2000 in fourth gear with full throttle. If this is not normal, how can I adjust?

-The exhuast makes a kind of burping sound. This is the best I can describe it. It is not terrible, but could this be a timing issue?

-How can I tell if the motor is a 80mm or 85 mm bore? Any signs from the outside? Considering the year this TEK was built, it should be the 85mm bore. However, it is showing the HP from the 80mm bore in the papers. Which can I trust?

I am grateful for any help I can get and also proud to be a new Ferguson owner. Pictures will be attached in a second post for your viewing pleasure. I also have a video of the TEK running is anyone is interested.

Thanks!

Chris from Germany

I recently got my hands on, at least what I think is, a Ferguson rarity. Although there is very little information available for the TEK variation, it is clear that it is mechanically identical to the later model TEAs. Finding any information about Frech built models is a challange in itself, but the serial plate is somewhat helpful. The color appears to be originally entirely red, but was repainted sometime in the past. I am looking for any and all information available regarding the TEKs. I hope some of you more experienced fellows can help me find out more.

The TEK itself is in very good condition and runs reasonably well. I suppose I will be constantly asking for your extensive knowledge and searching the forum for tips in the coming months. Although I will not be starting right away, I do want to make a plan. So, I do have a few questions for our more expereinced forum dwellers:

-Considering the TEK starts without issue and runs well, should I even be considering tearing the motor apart because of cleaning/servicing? Or would this just create more problems that it would solve?

-The trottle is sluggish and responds poorly. That would generally mean the carb is due for a teardown, correct?

-What is the RPM range for the TEA petrol motor? The TEK idles at 900/1000 RPM and only is reaching a RPM of 1900/2000 in fourth gear with full throttle. If this is not normal, how can I adjust?

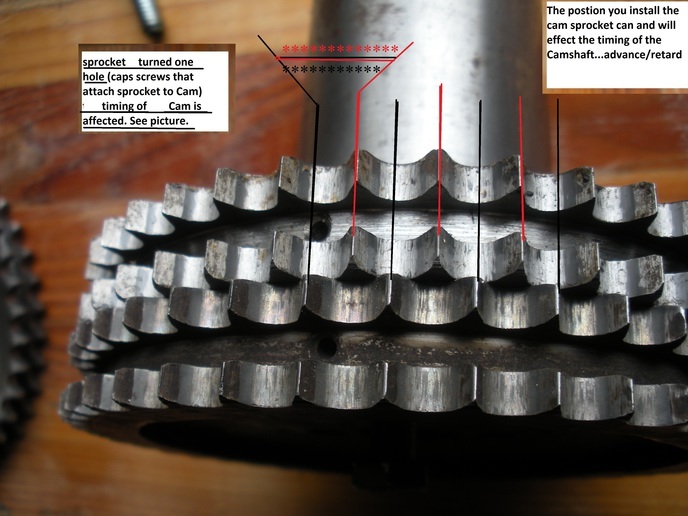

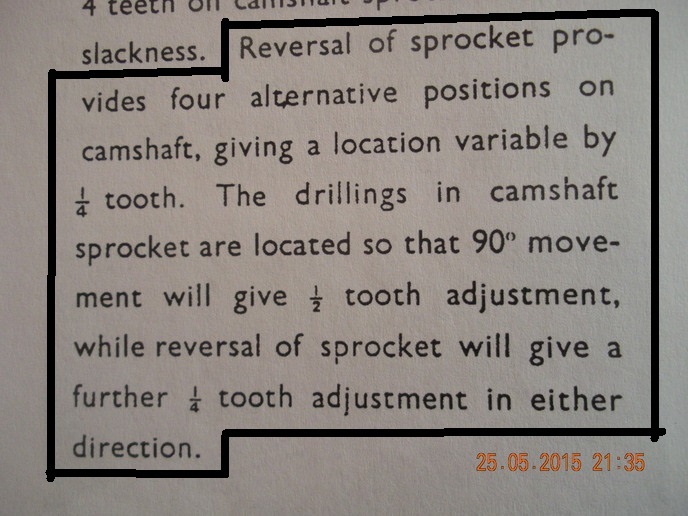

-The exhuast makes a kind of burping sound. This is the best I can describe it. It is not terrible, but could this be a timing issue?

-How can I tell if the motor is a 80mm or 85 mm bore? Any signs from the outside? Considering the year this TEK was built, it should be the 85mm bore. However, it is showing the HP from the 80mm bore in the papers. Which can I trust?

I am grateful for any help I can get and also proud to be a new Ferguson owner. Pictures will be attached in a second post for your viewing pleasure. I also have a video of the TEK running is anyone is interested.

Thanks!

Chris from Germany