I'm new to this tractor world, and have acquired a blue Dealer Shop manual, and owner's manual for my TO 30.

I have watched several you tubes of Rachel and others repairing hydraulics, and it is all starting to sink into head.

My lift does nothing, previous owner has the arms shimmed in the up position with a length of 2x4. I got this tractor four years ago after it sat unused in a damp garage since 1998. Got it running,and driving around dooryard. Now it's time to get the 3 point working.

25+ year old luid is up to correct level, and rather yellow/orange colored. I suspect it has some moisture contamination. Looking through fill hole atop transmission those gears look nice and shiny, no corrosion to be seen.

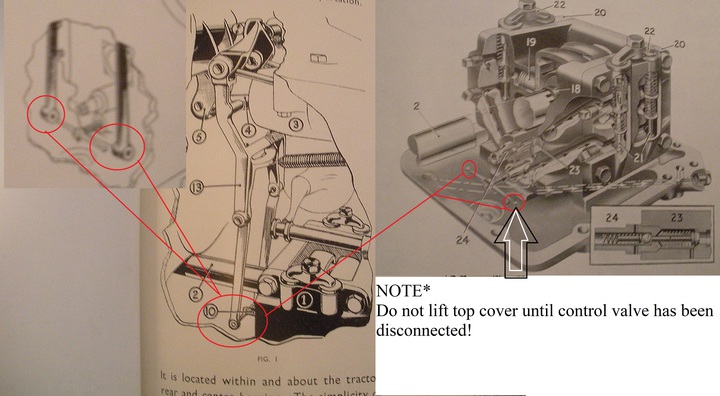

The control spring is snug and can be turned by hand, however its adjusting yoke is stuck from rust, and I did not force it. Plan is to cut plunger and replace with new plunger and yoke. I think I saw somewhere a Ford 9N matched plunger & yoke will fit the TO 30.

Before I remove the round inspection covers, will some of the hydraulic fluid need to be drained down below those openings?

From the You Tubes I gather the non-functioning hydraulic system could be fixed by simply replacing relief valve, or to performing a complete rebuild of pump and top lift piston.

The PTO turns, goes i and out of gear easily, however there was some nasty looking sludgy oil with shinny metal flake that came out when cover was removed. I haven't had the off since I first got the tractor. The shaft when turning looked to have a little run-out.

So what should I do first, look in through inspection holes and see what is or is not happening? Pull out relief valve, and control valve looking for crud plugging them, or what?

I have watched several you tubes of Rachel and others repairing hydraulics, and it is all starting to sink into head.

My lift does nothing, previous owner has the arms shimmed in the up position with a length of 2x4. I got this tractor four years ago after it sat unused in a damp garage since 1998. Got it running,and driving around dooryard. Now it's time to get the 3 point working.

25+ year old luid is up to correct level, and rather yellow/orange colored. I suspect it has some moisture contamination. Looking through fill hole atop transmission those gears look nice and shiny, no corrosion to be seen.

The control spring is snug and can be turned by hand, however its adjusting yoke is stuck from rust, and I did not force it. Plan is to cut plunger and replace with new plunger and yoke. I think I saw somewhere a Ford 9N matched plunger & yoke will fit the TO 30.

Before I remove the round inspection covers, will some of the hydraulic fluid need to be drained down below those openings?

From the You Tubes I gather the non-functioning hydraulic system could be fixed by simply replacing relief valve, or to performing a complete rebuild of pump and top lift piston.

The PTO turns, goes i and out of gear easily, however there was some nasty looking sludgy oil with shinny metal flake that came out when cover was removed. I haven't had the off since I first got the tractor. The shaft when turning looked to have a little run-out.

So what should I do first, look in through inspection holes and see what is or is not happening? Pull out relief valve, and control valve looking for crud plugging them, or what?