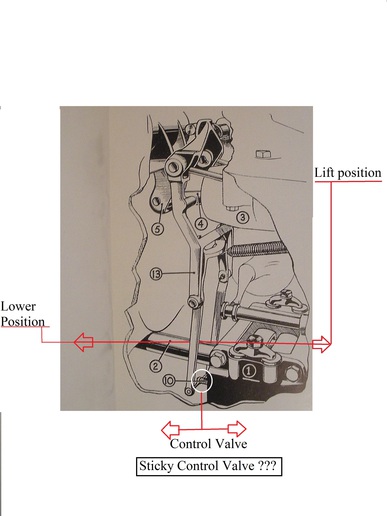

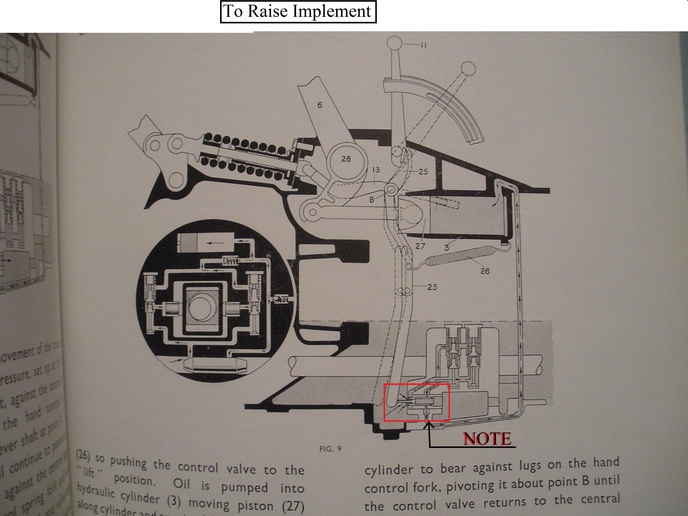

My TO20's hydraulics have generally been working fine, but this spring the arms started sticking in the up position with weight on them. They will eventually come down. A little working the control back and forth seems to encourage it a bit.

The arms lift fine, although sometimes with something really heavy, like the brushhog, something goes KLUNK-KLUNK-KLUNK_KLUNK on the way up.

The fluid looks good, but a bit over-full.

I am hesitant to go poking around in the hydraulic system without a clear plan.

Any ideas?

Thanks,

David

The arms lift fine, although sometimes with something really heavy, like the brushhog, something goes KLUNK-KLUNK-KLUNK_KLUNK on the way up.

The fluid looks good, but a bit over-full.

I am hesitant to go poking around in the hydraulic system without a clear plan.

Any ideas?

Thanks,

David