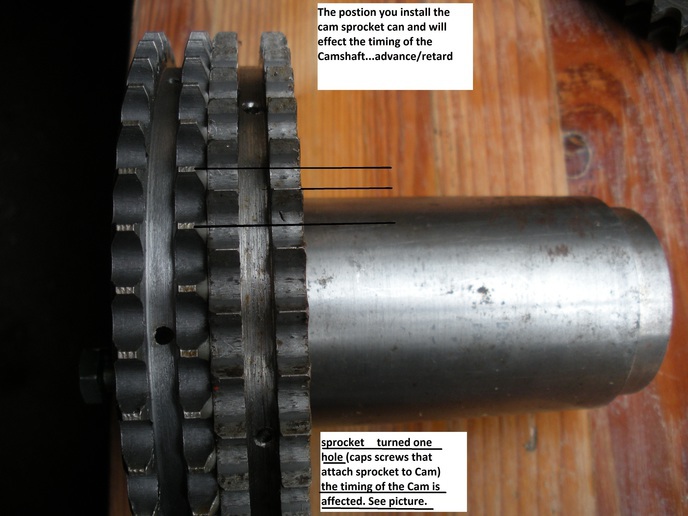

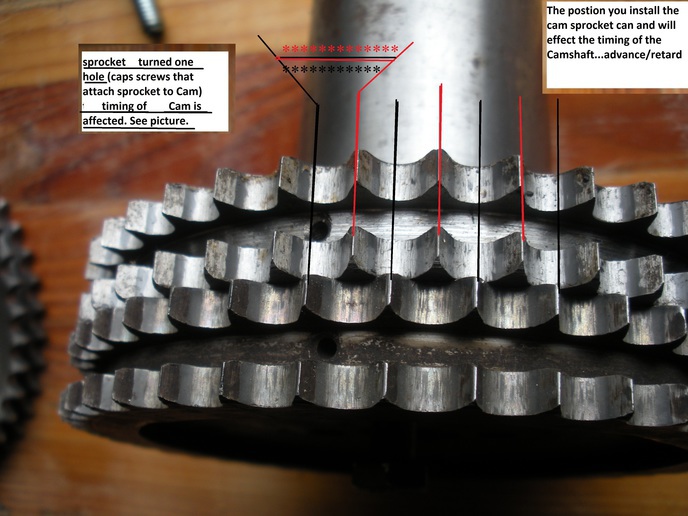

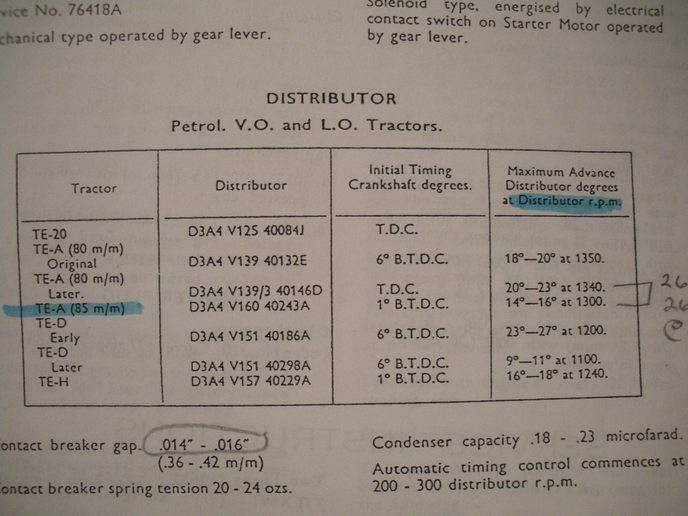

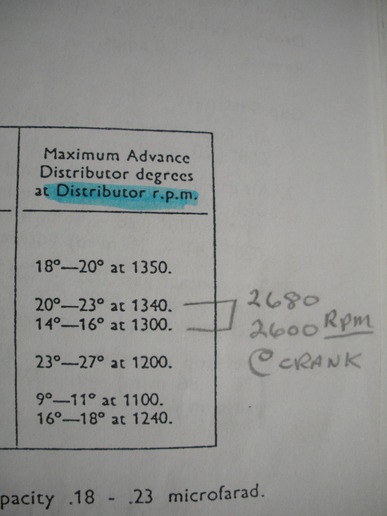

I bought a tea 20, not running. Noticed the distributor was out (clockwise from its normal position by about 90 degrees) I adjusted the timing (hole in flywheel on No. 1 cylinder, rotated the distributor set points ) and tried to start engine. Sounded like it was firing back on itself. I moved the distributor back to the position it was originally found in (about 90 degrees clockwise from its normal position) and the tractor started. It seems to run pretty good. A little low in power but not bad. Originally I thought the timing chain had jumped gears but it seems to run too well. Compression is also good in all cylinders (95-110 psi) Any ideas as to why the distributor seems to be 90 degrees out. This is hard to time like this as the reference point (hole is the flywheel) cannot be used.

Thanks Steve

Thanks Steve