Before taking anything apart, remove the right round inspection cover, have a flash light ready.

Have an implement on the 3 point, or chain the 3 point down to a midway position. Start the engine, tell it to lift.

Look inside BUT DON'T REACH IN!!!

Looking up you will see the bottom of the lift cylinder. Some dripping of oil past the piston is normal, but should not be streaming.

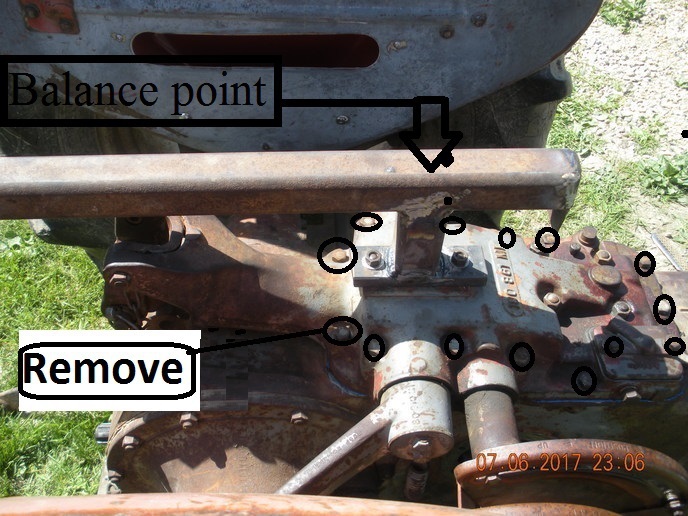

In the bottom photo, the 2 bolt cap, under that is the standpipe. That is where the oil comes up from the pump. There are orings at top and bottom of the pipe. Any oil driping down or boiling up from below indicates a blown oring. They can be changed from up top.

When the 3 point is going up, is the lift smooth and steady, or jerky? If it is jerky, the pump valves are bad, a common problem with those.

But, bad pump valves won't effect the leak down rate. They were never intended to hold position with the engine off. The piston uses iron rings, so never a perfect seal.

If you do go in after the pump, or plan on taking the top cover off, best have a shop manual in hand first!

Dealing with the control linkage is critical, the components are fragile, the cover is heavy! Don't try to lift it off by hand by yourself! The linkage you see through the inspection cover goes all the way up to the cover, it all comes out the top.

There was a major change in the hydraulics at some point in production. I don't have the info here today, but it involved the pressure setting (the relief valve), the design of the top cover, and the diameter of the lift cylinder bore.

The early model, low pressure system, used a 2 1/2" piston bore, the later high pressure system uses a 3" piston bore. The parts and pressures cannot be interchanged, going with high pressure on a low pressure model will break the top cover!

If the pump turns out to need valves, and everything else is good, then just replace the valves. Going deeper into the pump is an exacting area of measurement and clearances. Buying the replacement parts and expecting them to fit is not likely to happen. Best buy a rebuilt pump. BUT, call and compare, or send the old pump in first for comparison because there were several changes and confusion over serial number changes. Be sure the proper relief valve is in the pump. Again, I don't have the book here, but there is a high and low pressure, be sure to get the right valve, and don't reuse the old one, they are known to rust and erode internally.

While the top cover is off, be a good time to replace the draft link boot. It can be quite a job. Typically the rod will not unscrew and will have to be cut with a Sawzall working between the spring coils. Best do it now than later... Without a good boot water will enter the transmission. There are intricate adjustments to be done in the spring preloading procedure, a shop manual is a must!

Have fun! This is not a pleasant job, but doable. Just be careful, take pictures, get a manual, ask questions!