Dan S (NY)

Well-known Member

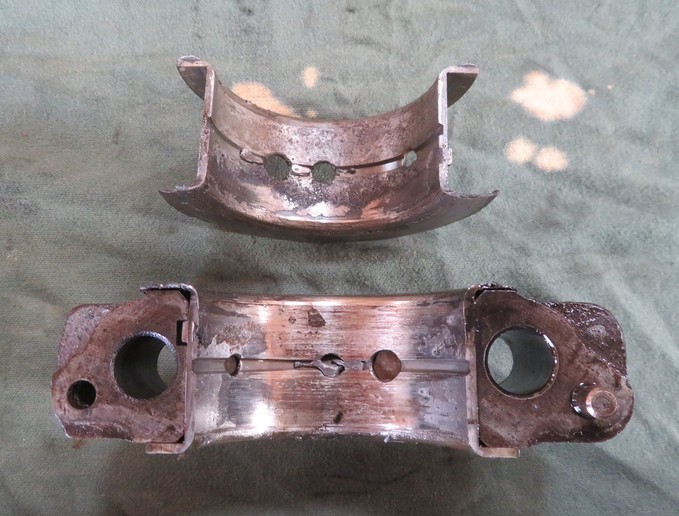

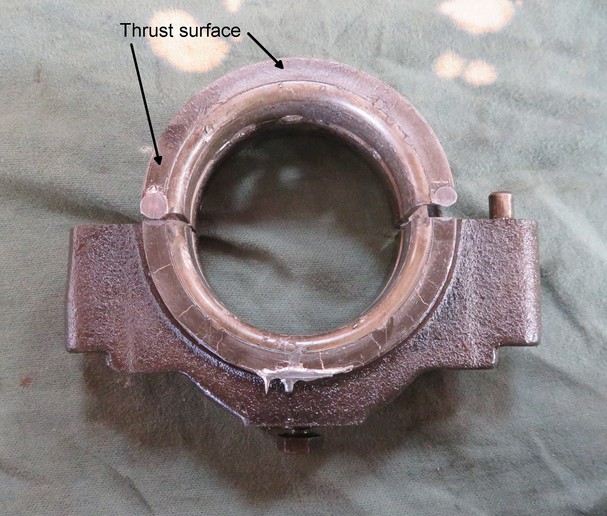

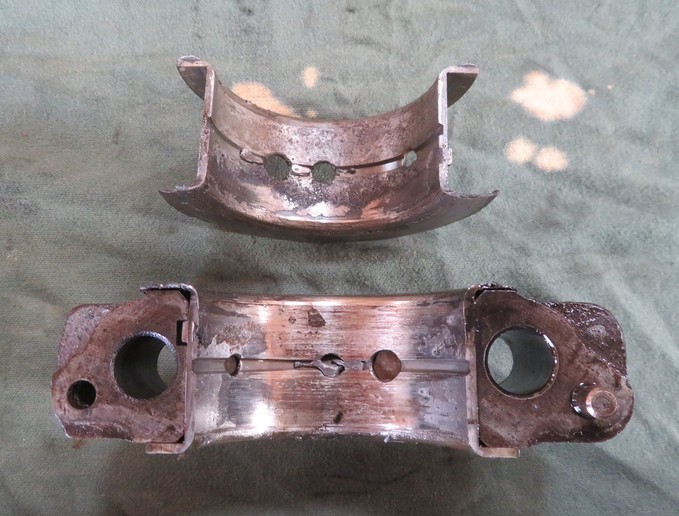

I have a spare engine I want to install in the MF50 I got with the rod through the block. The spare engine was in a 1955 TO35 parts tractor I bought and seemed to run pretty well from what I remember except for a rear oil leak so I wanted to fix that first. Once I put it on the stand, I noticed the crank had a lot of end play, so that wasn't a good sign. Once I had the crank out, most of the bearings looked pretty good except the center main, which as you can see in the pictures, isn't pretty. I have blown through all the oil galleys and they appear to be clear and the other bearings didn't seem to suffer from lack of oil. I don't know what the oil pressure was, but the pump appears functional. Any idea why only the center main would disintegrate like this? It feeds oil to the number two and three rods and #2 rod bearing looked good. The #3 rod bearing had some flaking though. There is some bearing metal in the oil hole but not sure if that caused the issue or was the result of the bearing failing for some other reason. I am going to take the crank to the machine shop and see if it can be turned.

Dan

Dan