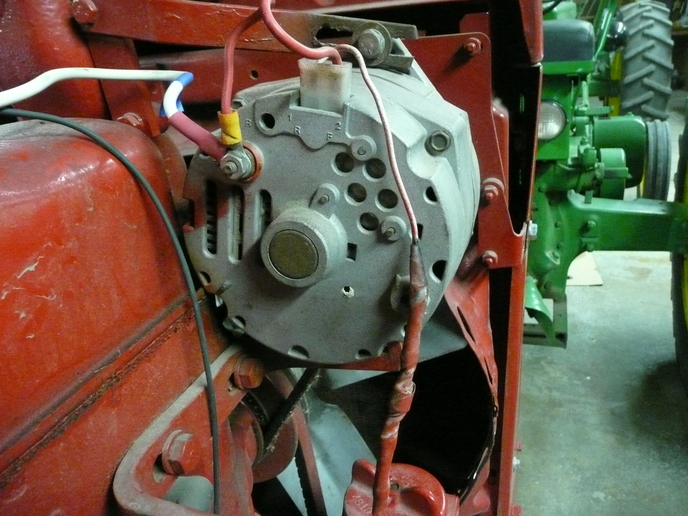

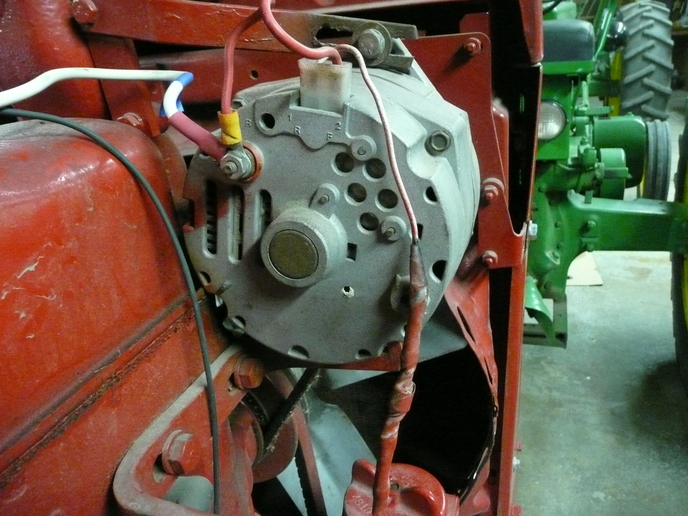

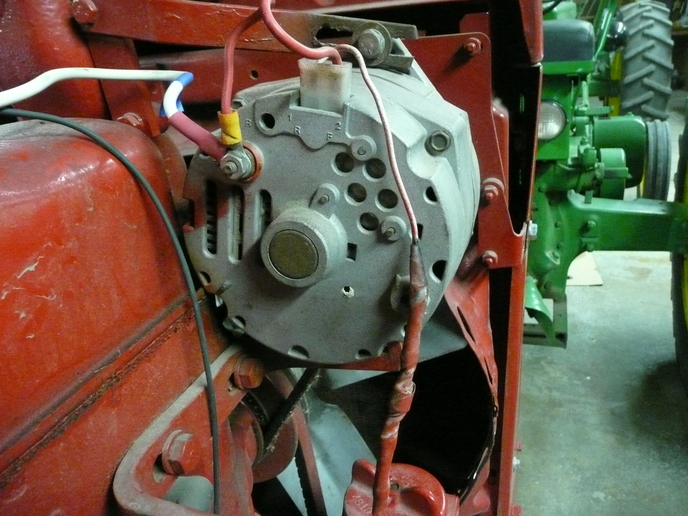

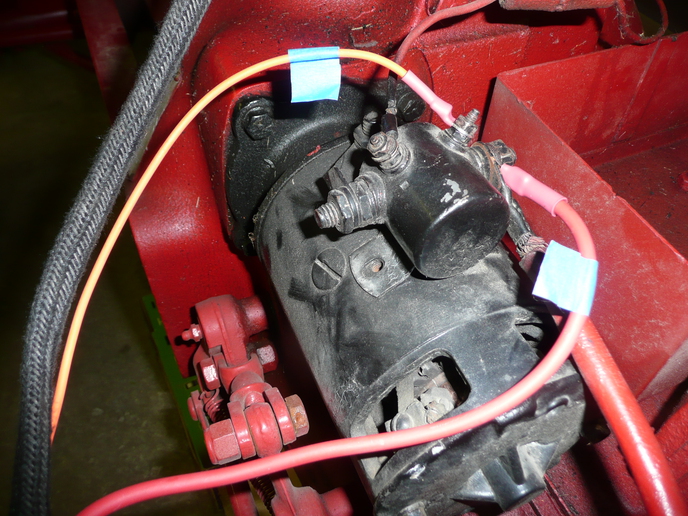

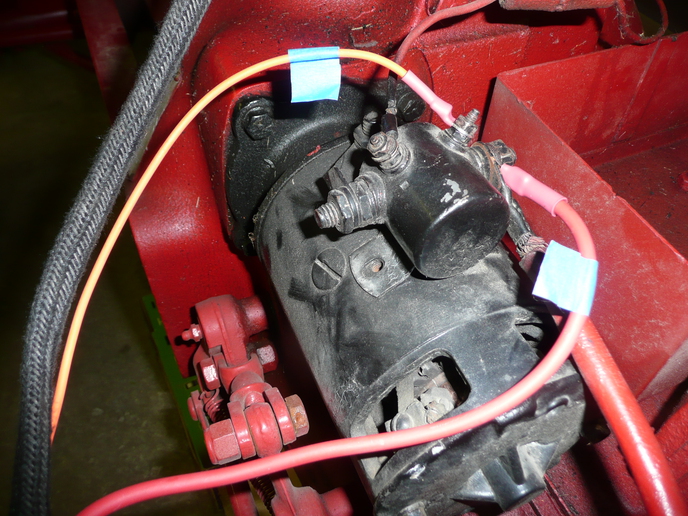

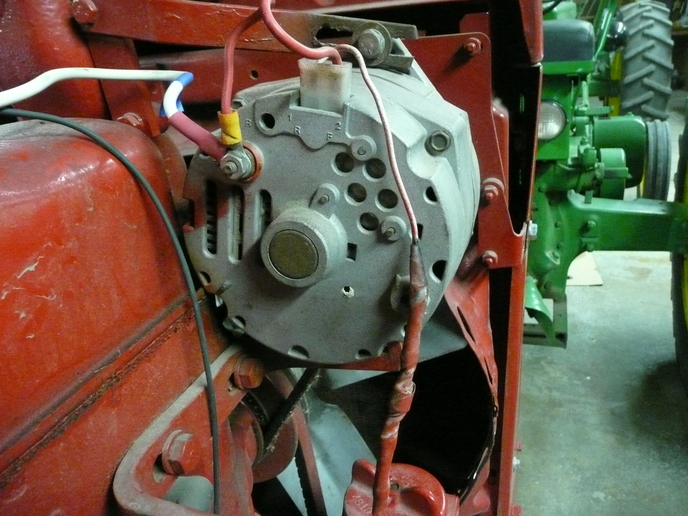

Here's a photo of the alternator. I couldn't see any identification - but didn't look anywhere I couldn't see without moving it.

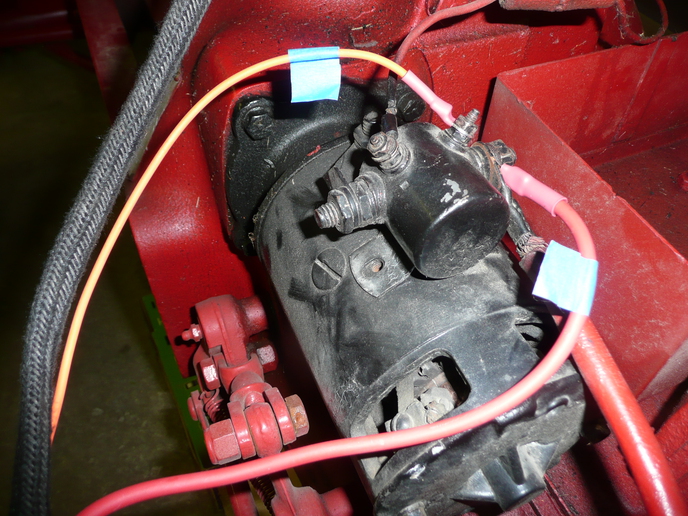

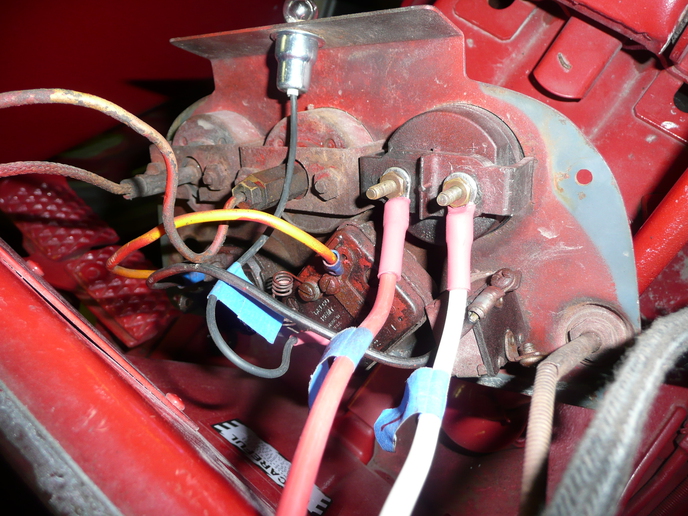

I finished a "rough-in" of the new wire harness. Everything works except I need to change the ammeter wires around - one of those things that are easy to get connected wrong.

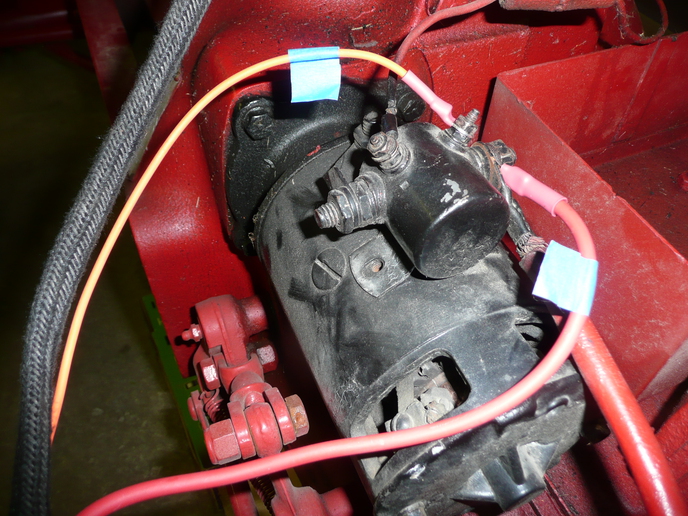

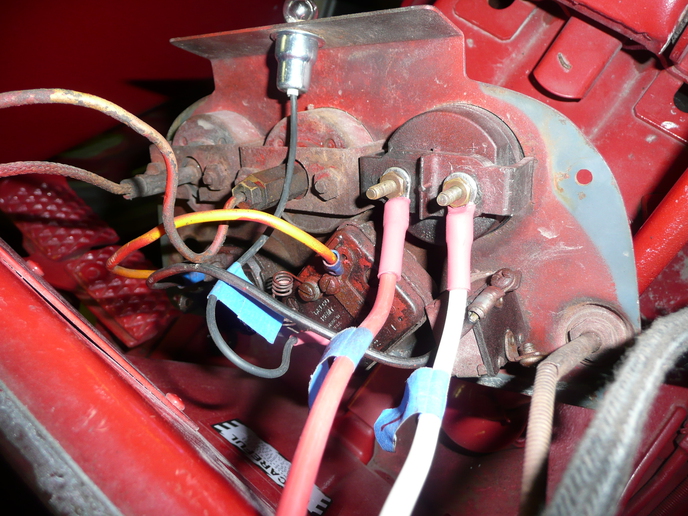

What resistance should be measured between the two small terminals on the starter solenoid?

Also between the battery terminal and the "start" small terminal?

I was a bit puzzled by what I measured (7.2 ohms and 4.8k ohms respectively), but since everything works, those resistances must be at least close.

Solenoid photo also attached plus a couple

(front and back) of the dash panel.

I'll be "neating up" the harness - just wanted to see if it all worked first.

SORRY FOR DUPLICATE PHOTOS

I finished a "rough-in" of the new wire harness. Everything works except I need to change the ammeter wires around - one of those things that are easy to get connected wrong.

What resistance should be measured between the two small terminals on the starter solenoid?

Also between the battery terminal and the "start" small terminal?

I was a bit puzzled by what I measured (7.2 ohms and 4.8k ohms respectively), but since everything works, those resistances must be at least close.

Solenoid photo also attached plus a couple

(front and back) of the dash panel.

I'll be "neating up" the harness - just wanted to see if it all worked first.

SORRY FOR DUPLICATE PHOTOS