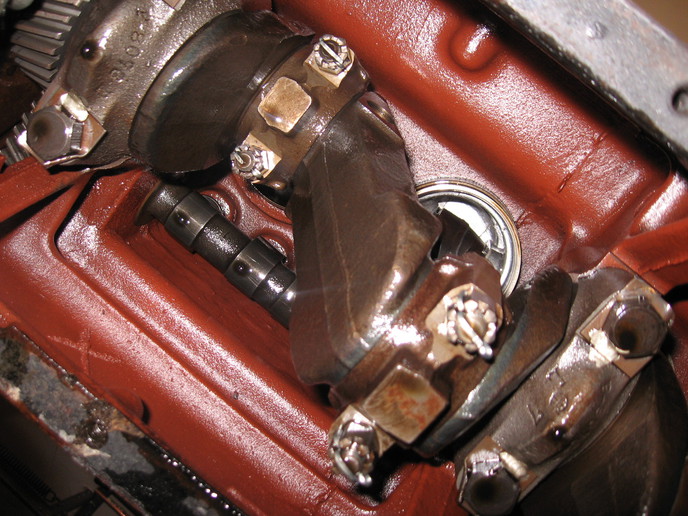

Man, a tractor sure does come apart fast when you have 8 hands doing all the work for you.

The 4h kids are working out better than I expected. They did all this last night, I was hands off, just coaching.

They're learning fast, and they're all putting in a solid effort.

Next step is all the heavy stuff - block it all up, pull the front end, yank the engine, take off the back wheels and final drives.

Just searching for a cheap engine hoist now...

The 4h kids are working out better than I expected. They did all this last night, I was hands off, just coaching.

They're learning fast, and they're all putting in a solid effort.

Next step is all the heavy stuff - block it all up, pull the front end, yank the engine, take off the back wheels and final drives.

Just searching for a cheap engine hoist now...