I put new Cam Gear on, but can't get it on all the way.

There's too much back slop on the shaft, and as I'm rubber hammering the gear on, it bottoms out on the engine face with about 3/8" to go yet. The shaft floats back as I'm hitting the gear. I have heated the gear for easier fit.

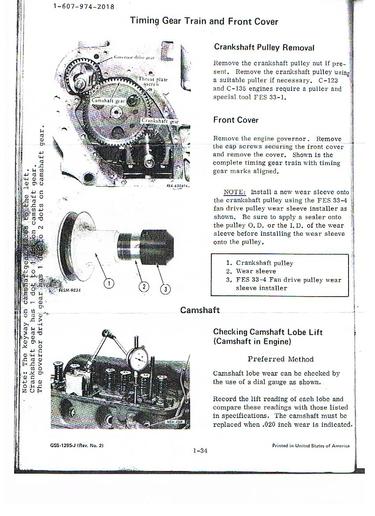

So, either i pull the Cam Shaft, which I'm not sure how.

Or, what if i welded a bolt on the end of shaft and simply screwed down with a plate and squeezed the gear back on.

Will welding on the shaft cause cracks?

Or - is there another trick to do this?

Bruce

There's too much back slop on the shaft, and as I'm rubber hammering the gear on, it bottoms out on the engine face with about 3/8" to go yet. The shaft floats back as I'm hitting the gear. I have heated the gear for easier fit.

So, either i pull the Cam Shaft, which I'm not sure how.

Or, what if i welded a bolt on the end of shaft and simply screwed down with a plate and squeezed the gear back on.

Will welding on the shaft cause cracks?

Or - is there another trick to do this?

Bruce