I have a "49 Farmall M with a 3-point hitch on it, which runs off the factory Lift-All hydraulics. The hitch is partly aftermarket, partly homebrewed linkages, so using it has been a learning process.

Since I bought it, I"ve had to lift both control rods (main lift and Remote Control lift) to raise the 3-point. Only after I received the manual from my father via YT (thanks, Dad!) did I read that this should not be so!

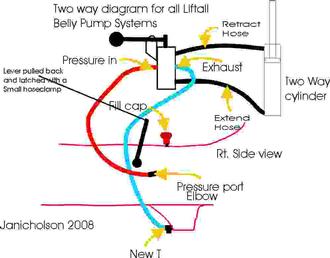

I inspected it today, and it turns out that the PO routed the main hydraulic line from the right side of the tractor to an inlet on the left side of the Remote Control valve body, then routed the pressure line from the upper rear port on the Remote Control valve body to the pistons on the 3-point hitch. He then routed the return from the pistons to the lower rear port on the Remote valve body.

As such, I have to engage the main hydraulics, then ALSO engage the remote hydraulics, to raise the 3-point. Can anyone think of a reason why he would do it this way, rather than just running the pistons off the main hydraulics? There are no other lines on the tractor, and both ports on the left side of the tractor are capped, so it"s not like he was using it for some other implement. I"d appreciate it if someone could post a picture of how their stock hydraulics are run, particularly focusing around the main and remote hydro units.

Another issue I noted while inspecting the tractor is the filler cap/vent valve for the hydraulic system. The filler cap came off fine, but the dipstick looked odd, so I removed it. It turned out to be a 3" section of threaded rod with a nut and washer welded to it to form a stop; this sat on top of the filler neck, under the filler cap. The threaded rod was then welded to a long flat section, about 1/4" wide by 3/32" thick, by about 15" long, presumably the original dipstick. The end of this flat stick was in turn welded to a 1/4"x3" round chunk of ANOTHER dipstick, which is stamped with a couple horizontal lines and an arrow. Could someone post a pic of what"s actually supposed to be in there?

As a side note, the book says there"s supposed to be a "vent valve" on top of the filler cap, and that this is somehow used for the proper operation of the remote hydraulics system. But my cap only has a small (1/16") hole, no valve. What SHOULD be there?

Lastly, the book states that the "Hydraulic Lift-All will lift or drop either the right or left sections of an implement independently of the other, as in the case of cultivators, two-way plows, etc." How would one go about raising the right or left independent of the opposite side? I know about the delay circuit on the left side of the tractor, but that raises AFTER the main circuit, both raising and lowering, and is not exactly independent.

Any help is most appreciated!

Regards,

Nick

Since I bought it, I"ve had to lift both control rods (main lift and Remote Control lift) to raise the 3-point. Only after I received the manual from my father via YT (thanks, Dad!) did I read that this should not be so!

I inspected it today, and it turns out that the PO routed the main hydraulic line from the right side of the tractor to an inlet on the left side of the Remote Control valve body, then routed the pressure line from the upper rear port on the Remote Control valve body to the pistons on the 3-point hitch. He then routed the return from the pistons to the lower rear port on the Remote valve body.

As such, I have to engage the main hydraulics, then ALSO engage the remote hydraulics, to raise the 3-point. Can anyone think of a reason why he would do it this way, rather than just running the pistons off the main hydraulics? There are no other lines on the tractor, and both ports on the left side of the tractor are capped, so it"s not like he was using it for some other implement. I"d appreciate it if someone could post a picture of how their stock hydraulics are run, particularly focusing around the main and remote hydro units.

Another issue I noted while inspecting the tractor is the filler cap/vent valve for the hydraulic system. The filler cap came off fine, but the dipstick looked odd, so I removed it. It turned out to be a 3" section of threaded rod with a nut and washer welded to it to form a stop; this sat on top of the filler neck, under the filler cap. The threaded rod was then welded to a long flat section, about 1/4" wide by 3/32" thick, by about 15" long, presumably the original dipstick. The end of this flat stick was in turn welded to a 1/4"x3" round chunk of ANOTHER dipstick, which is stamped with a couple horizontal lines and an arrow. Could someone post a pic of what"s actually supposed to be in there?

As a side note, the book says there"s supposed to be a "vent valve" on top of the filler cap, and that this is somehow used for the proper operation of the remote hydraulics system. But my cap only has a small (1/16") hole, no valve. What SHOULD be there?

Lastly, the book states that the "Hydraulic Lift-All will lift or drop either the right or left sections of an implement independently of the other, as in the case of cultivators, two-way plows, etc." How would one go about raising the right or left independent of the opposite side? I know about the delay circuit on the left side of the tractor, but that raises AFTER the main circuit, both raising and lowering, and is not exactly independent.

Any help is most appreciated!

Regards,

Nick