Changed the clutch, pressure plate, throw out bearing and carrier on

a Super A.

Tractor will not come out of gear or respond to the clutch in anyway. I

can observe the throw out bearing pushing the fingers enough that

the pressure plate completely comes off the clutch disk. However, the

clutch doesn’t seem to be coming off the flywheel, and the shaft

never stops.

When I tested it initially, the clutch worked one time to stop the

tractor. I didn’t change gears, just stop and go. The next time I

pressed clutch, i had no clutch. Resplit the tractor to make sure

everything is in the right way (I was afraid the bushing inside of throw

out bearing carrier had slid forward enough it was pushing on clutch

and not allowing it to release). After putting the tractor back together

it still will not go into gear while running. Shaft does not stop while

clutch is pressed.

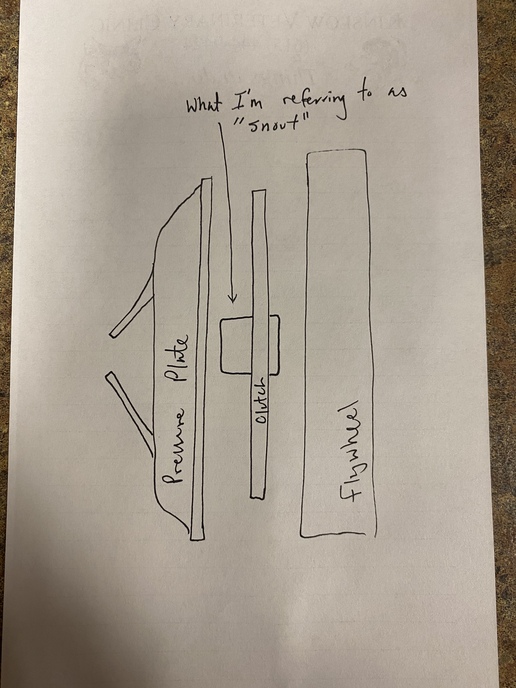

I put the longer “snout” end of the clutch disk towards the rear of the

tractor. This was the way the previous clutch was in so I assume it is

correct. I did not turn the flywheel on a lathe before reassembling, but

it seemed fairly clean and I wire wheeled it before assembly.

Only things I can think of at this moment:

-clutch is in backwards

-flywheel not being turned leaves the surface rough enough that

clutch is “letting go” of it

-somehow tip of shaft is stuck/in a bind with the pilot bushing/hole

and this keeps the shaft turning even though the pressure plate is off

the clutch

-somebody sent me the wrong clutch or I ordered the wrong clutch

Really want to avoid splitting it the 4th time but pretty much expect to

have to split the tractor a third time to correct whatever is current

going on. Thanks for any help.

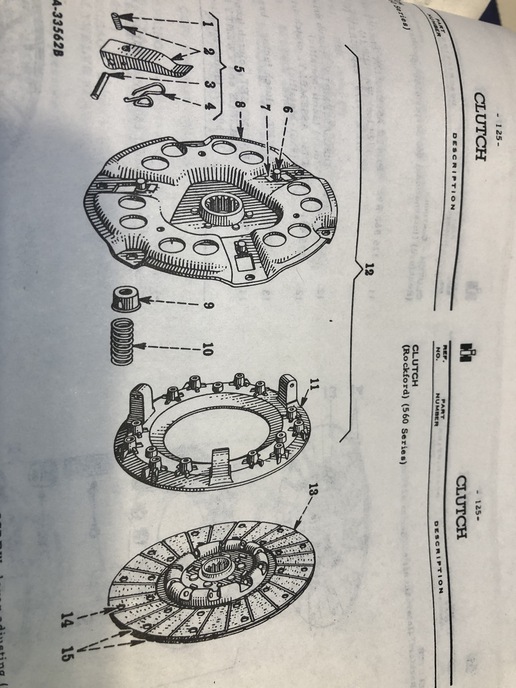

Clutch kit I ordered for Super A

a Super A.

Tractor will not come out of gear or respond to the clutch in anyway. I

can observe the throw out bearing pushing the fingers enough that

the pressure plate completely comes off the clutch disk. However, the

clutch doesn’t seem to be coming off the flywheel, and the shaft

never stops.

When I tested it initially, the clutch worked one time to stop the

tractor. I didn’t change gears, just stop and go. The next time I

pressed clutch, i had no clutch. Resplit the tractor to make sure

everything is in the right way (I was afraid the bushing inside of throw

out bearing carrier had slid forward enough it was pushing on clutch

and not allowing it to release). After putting the tractor back together

it still will not go into gear while running. Shaft does not stop while

clutch is pressed.

I put the longer “snout” end of the clutch disk towards the rear of the

tractor. This was the way the previous clutch was in so I assume it is

correct. I did not turn the flywheel on a lathe before reassembling, but

it seemed fairly clean and I wire wheeled it before assembly.

Only things I can think of at this moment:

-clutch is in backwards

-flywheel not being turned leaves the surface rough enough that

clutch is “letting go” of it

-somehow tip of shaft is stuck/in a bind with the pilot bushing/hole

and this keeps the shaft turning even though the pressure plate is off

the clutch

-somebody sent me the wrong clutch or I ordered the wrong clutch

Really want to avoid splitting it the 4th time but pretty much expect to

have to split the tractor a third time to correct whatever is current

going on. Thanks for any help.

Clutch kit I ordered for Super A