THe light switch is two switches on one shaft. One switch has control of the lights, one switch has control of the generator output.

The switches are rotated together and both have resistors in their circuit. The light switch is supplied from the amp meter through a 15 amp fuse, and is on Dim (through the wire wound resistor) in the third switch position, and Bright in the far CW position (direct 6 volt to lamps).

The first two switch positions are "off".

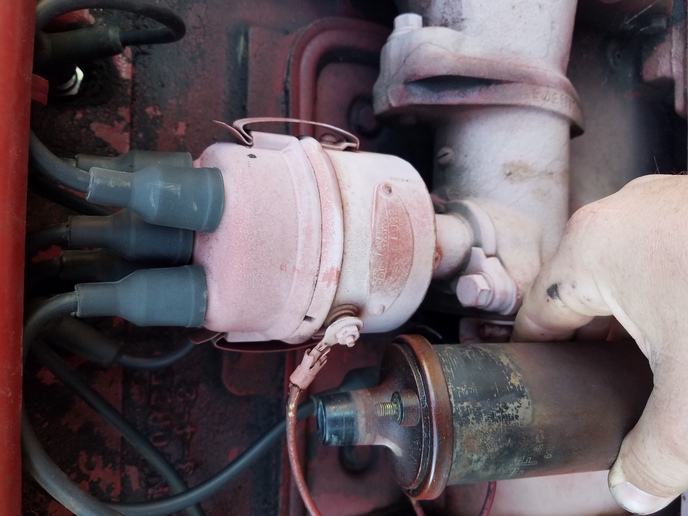

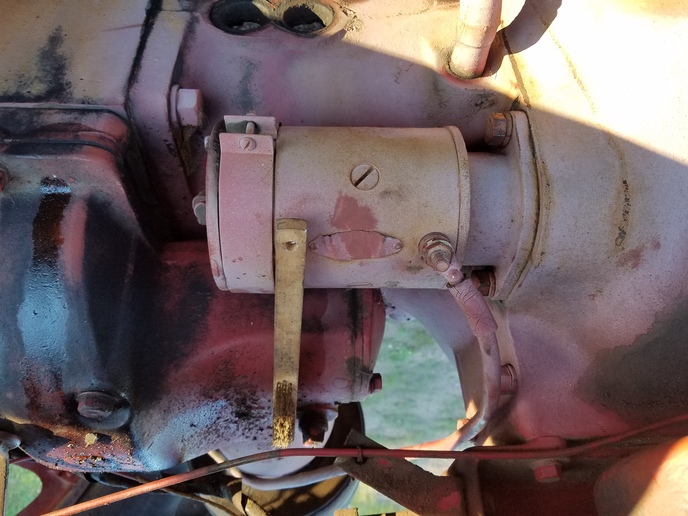

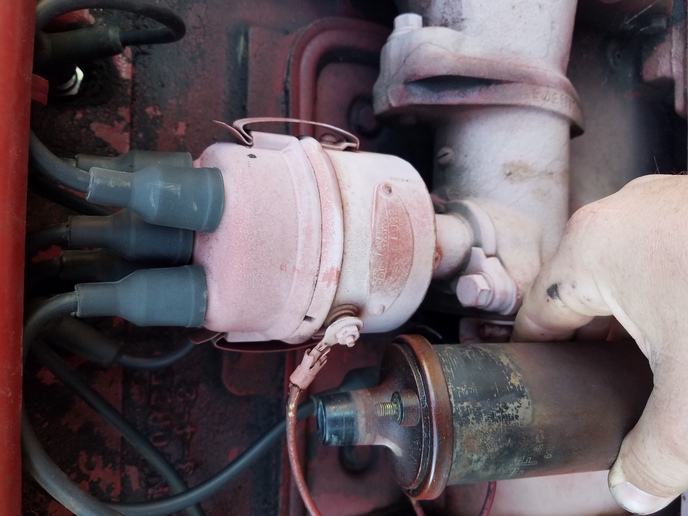

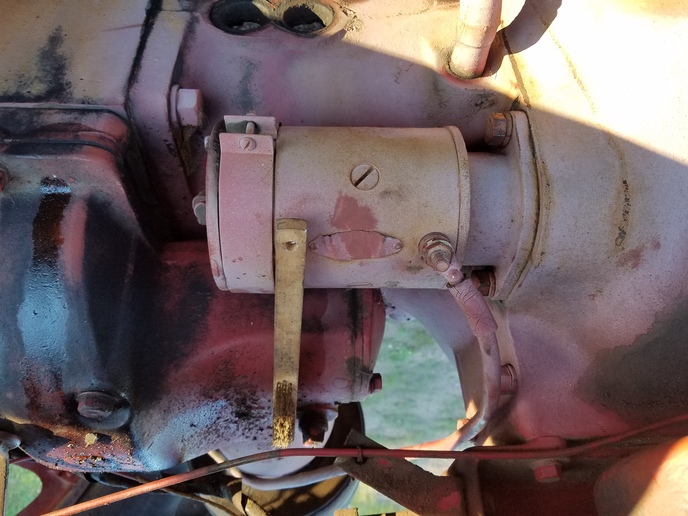

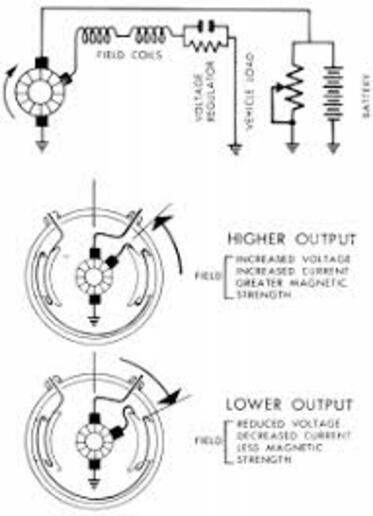

The Charge control is a grounding task, and the switch grounds the generator field either through a resistor, Low charge, or,directly to ground, High charge. the electrical path is a bit complex, bear with be. The generator has three brushes inside. One is connected to the Arm terminal of the VR. one is grounded, and one is adjustable, but near the brush connected to the Arm, not the grounded one. Electricity is sourced by this third brush, and sent to the gen field coils on the outside of the gen body. From there, the voltage needs to find ground o be complete/flow. The light switch provided that grounding. A single wire in the loom went from the F terminal, to the light switch for grounding. At the switch the field was always grounded (either some through a resistor, or fully directly through the switch body to the electrical box, through the steering support column, then the tractor frame parts to the grounded positive terminal(where the electrons ended up back in the battery soup.(remember electrons flow from negative to positive.

The gen output, when the tractor is shut off, is created by left over magnetism in the field pole iron. This electricity is strong enough to reach battery voltage when not connected to a big load, but strong enough to latch the cutout, connecting the battery to the generator. Now the fields have full power connection, and the charging voltage/current travels through the cutout, to the amp gauge, from there to the battery negative terminal. The field ( when a tractor is ordered with no lights) travels to the Cutout relay, where a simple resistor is used (separate from the cutout) to ground the F terminal through a resistor. This limits a "no lights" tractor to low charge all the time.

If a regulator is used, There is no use for the light switch grounding circuit, so the switch for the gen control is disconnected, or not there if OEM with a regulator. Regulator F terminals are the only thing connected to the F terminal of the gen. The vibrating points in the regulator (voltage control relay part) chop the electricity into bits, creating an average ground for the field, that controls output voltage of the gen. Nothing is as simple as it seems. Your generator field should not be under that screw. It may be wired so wrong that things will smoke or start fires if started. Jim

Info