I'm posting this here, rather than in the combine section, in the hopes that some experienced IH mechanic can advise me.

I'm trying to replace a leaking seal on the control valve assembly for the hydrostatic pump. It's the little o-ring and plastic ring that seals around the control valve shaft.

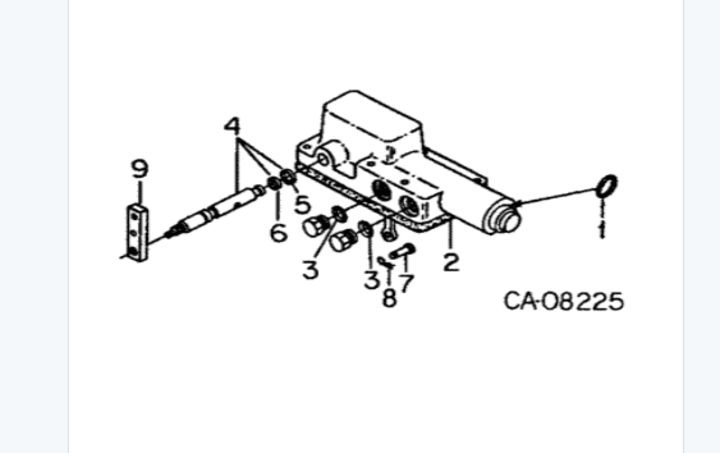

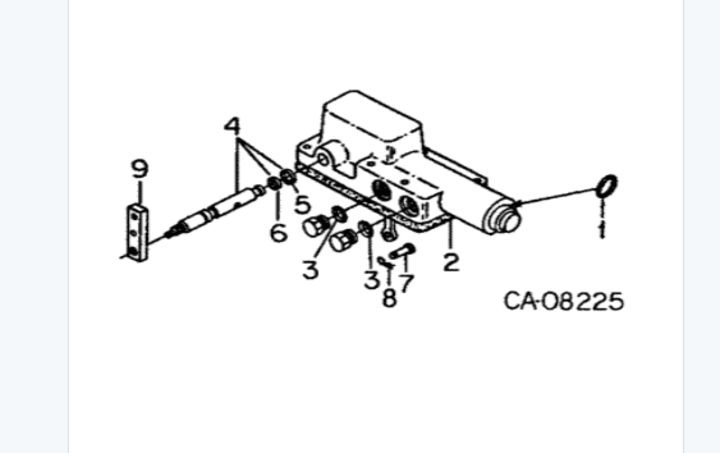

The problem is that I can't figure out how to remove the shaft (item 4 in the parts schematic) in order to replace the seals. I'm assuming this has to come out to do this.

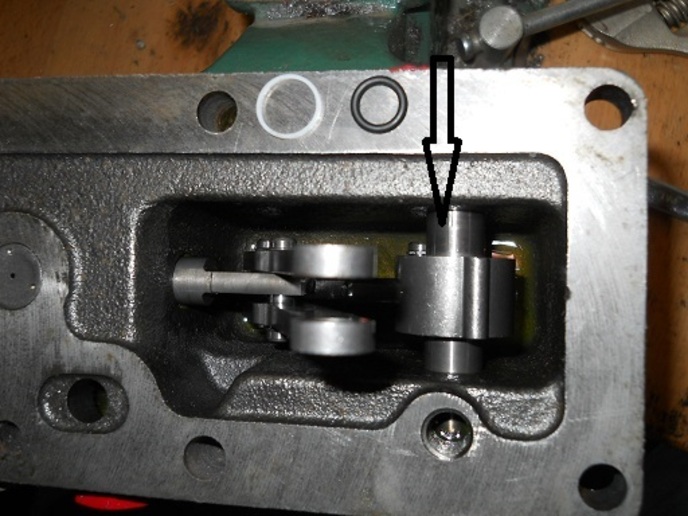

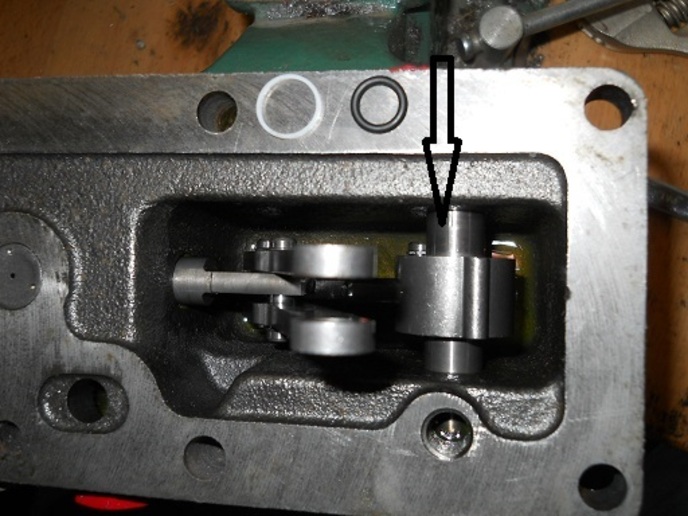

To remove the shaft, I need to drive a roll pin out from the linkage connecting collar (see arrow in picture). But I can't get a proper angle with a punch to get the friggin' roll pin all the way out! Only partially, but not enough to slide the shaft out (see picture).

Would really appreciate any advice from someone who has done this job before. Thanks!!

I'm trying to replace a leaking seal on the control valve assembly for the hydrostatic pump. It's the little o-ring and plastic ring that seals around the control valve shaft.

The problem is that I can't figure out how to remove the shaft (item 4 in the parts schematic) in order to replace the seals. I'm assuming this has to come out to do this.

To remove the shaft, I need to drive a roll pin out from the linkage connecting collar (see arrow in picture). But I can't get a proper angle with a punch to get the friggin' roll pin all the way out! Only partially, but not enough to slide the shaft out (see picture).

Would really appreciate any advice from someone who has done this job before. Thanks!!