I bought a non running F20 a few months back and finally got the time to tinker with it. The clutch did not operate at all so I took it apart. I slid the engine forward and removed the clutch cover , etc. (has Heisler overdrive). One thing I did notice looking from the inspection hole on the underneath side the clutch fingers were about a 1/2" to 9/16" away from the throw out bearing even with it all the way forward . There is no "spring" or resistance when you move the clutch lever the adjustment rod connects to. I can see the throw out bearing moves freely back and forth when manually pushing/pulling on the outside clutch cover lever. The throw out bearing never touches the clutch fingers when moved to the forward position. I did take the clutch pressure plate assembly apart and cleaned it thoroughly along with all the other parts, nothing was frozen or rusted together. What might be the reason the fingers don't even come close to contacting the throw out bearing. Everything was taken apart, cleaned and put back exactly like it was before I started. My thoughts are the 3 adjustable plungers/dogs that attach to the back of the fingers and pull the pressure plate in need adjusted out to allow the fingers to extend farther. I don't see how a gap between the clutch finger and throw out bearing this wide could come about without issues before hand. The clutch disk/pressure plate and all parts look very good - the tractor has been taken care of over the years for the most part. Steering is tight, radiator and gas tank are good, no dents, cracks or welds. Some of you guys have years/decades of experience. I appreciate your input. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Al in Il.

- Start date

caterpillar guy

Well-known Member

Could the flywheel have been faced and they didn't cut the edge/rim to fit the correct height setting causing them to be to far away from the throwout bearing. This would only be pertinent to a dished flywheel as a flat one would be surfaced completely.

The flywheel doesn't seem to have ever been resurfaced, you could tell by the way it looked. It appears to be flat and in good condition. I just don't see how the tractor could have ever moved with the fingers/throw out bearing never contacting, this is a mystery to me. I wedged a small block of metal about the width of the gap between one of the fingers and throw out bearing and there was resistance/spring when operating the clutch lever. Thanks for the thought Caterpillar Guy.

AL, I have seen clutch pressure plate stuck not moving so it does no spring back.

Most I take it all apart clean everything and get the plate moving again and fingers working.

the recess treaded plate adjusters I get the max out of them and that helps get the peddle back up.

Most I take it all apart clean everything and get the plate moving again and fingers working.

the recess treaded plate adjusters I get the max out of them and that helps get the peddle back up.

Janicholson

Well-known Member

is the clutch pressure plate actually clamping the disk? some IHC clutches have 3 bolts in the Pressure Plate that hold the PP in the released position for installing. they are the same size as the mounting bolts. (just thinking of possible realities). Jim

Hey Jim, The clutch pressure plate must be clamping the disk as it's stuck in gear and turns the engine over when the transmission lever is engaged. The clutch pedal does nothing when pushed in - found this out when trying to pull start. I assume the throw out bearing actually contacts/pushes the clutch fingers with nothing in between. The clutch itself and related parts are relatively simple to understand but I can't figure it out. Thanks Jim.

Oldiron29, The pressure plate worked fine when I took it off to clean and check. It still works, just cleaner now! I guess my next step is to move the 3 pressure plate bolts out farther and see if it will allow the fingers to contact the throw out bearing - or at least get close enough to function. Thanks for the reply Oldiron29!

used red MN

Well-known Member

- Location

- Coon Rapids, MN

First off let me say I have not been around an F20 or worked on one. Is it possible that the shaft that comes through the housing cover that connects to the part that moves the throw out bearing has come ..un-clocked..? Or in other words has a key sheared in there or it is loose not holding the shaft and the part in a proper rotational relationship? Since I have never found an IH part break down for the pre H-M tractors online they must not cover them. I used the linked video to at least in some way know what I wanted to suggest could apply to your tractor, it shows the clutch release shaft with a key way I am referring to on the work bench at the 18:15 minute mark. The author of the video Ken Christopherson is a poster here on YT. Hope this helps.

F20 clutch video

F20 clutch video

used red MN

Well-known Member

- Location

- Coon Rapids, MN

After I watched the video through to the end I think the thick washers shown at 21:30 set in the split of the parts that clamp on the shafts and engage in the key ways of the shafts. Still could be missing or sheared. He turn off the camera while he is actually assembling the throw out bearing into the clutch cover so I can't 100 percent verify my thick washer theory.

I had checked this also and everything is ok, nothing broke, missing or sliping. Even though the clutch is pretty

straightforward to understand, there's plenty to go wrong - as with many things. Thanks for the reply Used Red MN!

P.S. I had watched the video you posted several times before to get a good idea of what to expect/do. You are also

right about no online exploded views of F 20's - haven't found one yet.

Alan

straightforward to understand, there's plenty to go wrong - as with many things. Thanks for the reply Used Red MN!

P.S. I had watched the video you posted several times before to get a good idea of what to expect/do. You are also

right about no online exploded views of F 20's - haven't found one yet.

Alan

Janicholson

Well-known Member

If the clutch friction plate is in backwards, the disk will be too fat, and the fingers won't reach. The thick part of the disk must face rearward. jim

Jim, The clutch disk is in the correct position. Several of you have mentioned probable causes and I appreciate the ideas and thoughts. Unfortunately none of the tips are the reason for the clutch not working. My next attempt is to adjust the 3 pressure plate bolts. We'll see how that goes and I'll let you all know one way or the other. Thank you.

Janicholson

Well-known Member

One more idea. What if the pressure plate is incorrect. or the T/O carrier in the wrong part number. There are many contributors on here that could share part numbers and sizes with you. The simple fact is that the finger adjustment is usually only wrong when someone has screwed them in or out. 99% are good to go from the factory or rebuilder. The step face could be incorrect if the mounting rim was ground down too much and the system put back together. Most fingers are situated (when installed and pretty new) shch that they are not quite flat to each other. A theoretical cone formed by them would be toward the T/O bearing, but not much. If yours are way dished inward toward the engine, the issue is there, not with linkage. Jim

James Williams

Well-known Member

Al,I ran into the same problem on a F20,I never figured it out.I put small flat washers between the flywheel and pressure plate and It worked perfect.Thats been 15 years ago and its still working

Jim, You are right about the finger adjustment. I screwed them in and out and everywhere in between with no success. I noticed they only protrude so far out before contacting the backplate ( I think that's what IH calls it) so it looks like there's just one general setting - referring to your 99% are correct statement. SOMETHING is wrong/incorrect. And yes, the linkage has nothing to do with the actual problem. The throw out bearing travels the entire length ( about an 1-1/2") on the release sleeve. It goes all the way back/rearward and all the way forward but is 1/2" to 9/16" inches short of touching the clutch fingers when all the way forward - and of course about 2" away when all the way back . The clutch fork the throw out bearing rides in does contact the inside clutch cover when it moves backward pushing the throw out bearing forward. This effectively stops the forward travel of the throw out bearing but, it does move it all the way to the end of the release sleeve before touching the cover. I've compared my clutch/pressue plate with ones advertised on Ebay, etc. and they look/are exactly the same. I will EVENTUALLY figure this problem out but - guys like you can cut the time down considerably! Thanks again Jim.

Now that's interesting! I was hoping someone had the same experience. Everything is functioning with nothing stuck, broke, etc. I am so stumped. I was thinking of doing something like you did temporarily - maybe even permanent if it worked or was safe. Thanks for the reply James.

Whiskey Bent

Member

I have never worked on a f-20 so just guessing here, is it possible that the throw out bearing is wrong to short? Or collapsed?

Just thinking, the throw out carrier could be incorrect. Don't know if I could post a pic of it on the forum - somewhat computer illiterate. Emails I can do though. Someone could post a pic of the correct bearing to see/compare with what I have if possible or hopefully I could read a bearing number.

Quick story: About 2 years ago my 1953 Ford Jubilee engine started ticking abnormally so I took the head off. It had a cracked (in half) #1 piston. It had been overhauled in 1992 shortly after I bought it. The problem was the replacement sleeve had no "ring" at the top to keep it from moving up/down in the block. Eventually (26 years later) the sleeve slid down the block bore contacting the rotating crankshaft chipping/breaking the sleeve apart - hence the tick. As the sleeve got lower and lower in the block, the piston travel stayed the same of course until the top piston ring finally expanded over the top of the sleeve pulling it down and cracking the piston in half. I ordered one set of rings, sleeve and piston from this website and it's ran great since. Been finish mowing my 5 acres for the last 28 years. Tractors like people have problems when they get old don't they?

Quick story: About 2 years ago my 1953 Ford Jubilee engine started ticking abnormally so I took the head off. It had a cracked (in half) #1 piston. It had been overhauled in 1992 shortly after I bought it. The problem was the replacement sleeve had no "ring" at the top to keep it from moving up/down in the block. Eventually (26 years later) the sleeve slid down the block bore contacting the rotating crankshaft chipping/breaking the sleeve apart - hence the tick. As the sleeve got lower and lower in the block, the piston travel stayed the same of course until the top piston ring finally expanded over the top of the sleeve pulling it down and cracking the piston in half. I ordered one set of rings, sleeve and piston from this website and it's ran great since. Been finish mowing my 5 acres for the last 28 years. Tractors like people have problems when they get old don't they?

Janicholson

Well-known Member

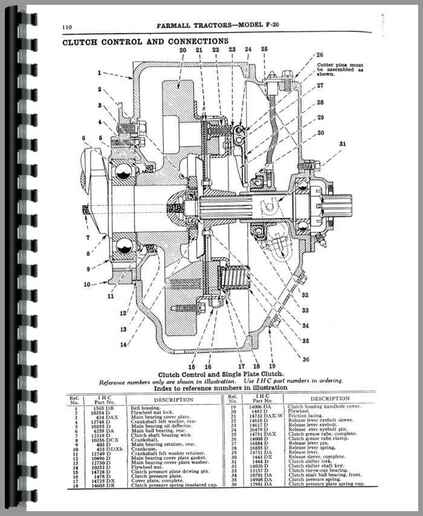

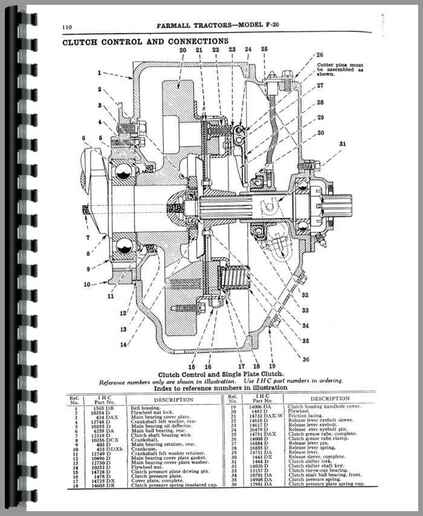

I found a cross swction of the assembly. It does not show adjustment screws on the fingers. I believe you may have the wrong pressure plate, as I have seen only those woth no screws. The mounting holes might be exactly the same as the correct Plate!. Jim

Iv'e got it all apart now with all parts off. Yes, the clutch etc. is pretty easy to understand how it

works/operates. Everything seems to be original and in good condition. That's what makes it so frustrating. I just

finished working on a stuck clutch on an M today. Dropped the belly pump etc. Wasn't difficult, just took time.

works/operates. Everything seems to be original and in good condition. That's what makes it so frustrating. I just

finished working on a stuck clutch on an M today. Dropped the belly pump etc. Wasn't difficult, just took time.

Similar threads

- Replies

- 5

- Views

- 423

- Replies

- 14

- Views

- 318

- Replies

- 13

- Views

- 407

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy