Do you folks have any suggestions on pulling the steering sector gear on a Farmall M? I want to do this to tighten up the steering a bit.

I have already bopped the shaft with a sledge hammer and tried to get a pry bar under the gear. I even thought to drill and tap some puller holes in the gear but the gear is hard as a brick. Someone before me has already hammered on the stem and expanded the 1.0 dia. threads.

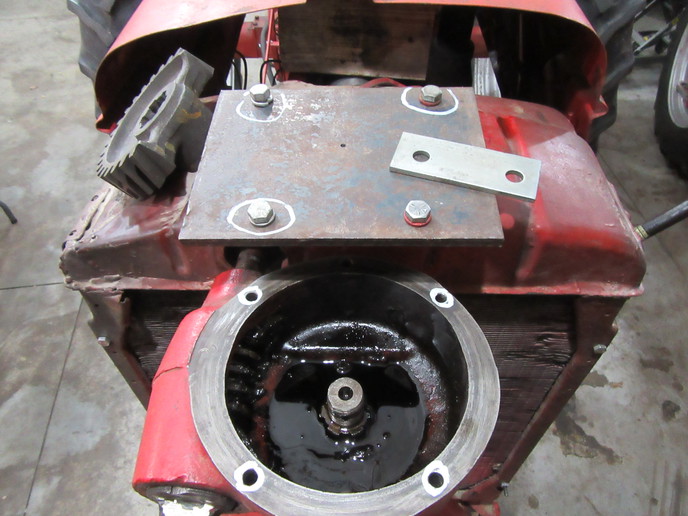

The front of the tractor is presently elevated slightly to allow for the stem to drop from the steering sector gear.

I was hoping you folks would have a good suggestion before I go into a self-destruct mode in getting this off.

I have already bopped the shaft with a sledge hammer and tried to get a pry bar under the gear. I even thought to drill and tap some puller holes in the gear but the gear is hard as a brick. Someone before me has already hammered on the stem and expanded the 1.0 dia. threads.

The front of the tractor is presently elevated slightly to allow for the stem to drop from the steering sector gear.

I was hoping you folks would have a good suggestion before I go into a self-destruct mode in getting this off.