hotdawg1984

Member

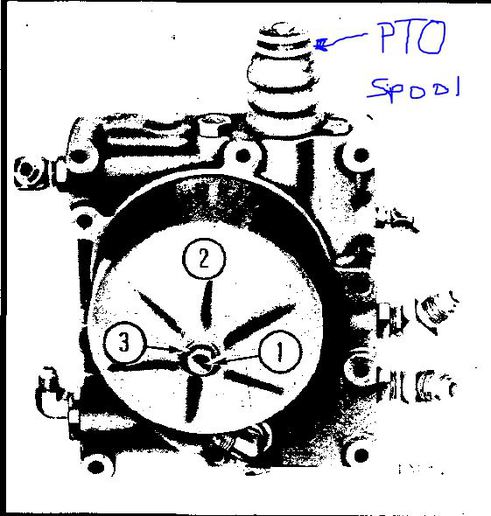

Hello everyone. Got a real problem with the PTO on my tractor.

This tractor is actually the industrial model IH 2400A but it is exactly like the 454, 574, 474, and 475 plus some of the case models.

It is the diesel model with the 3 cylinder engine. It has always been a very strong tractor and could mow down anything with my bush hog. HOWEVER, about 3 months ago it began to slow down when I hit heavy grass and now it is to the point where it won't even mow. it will turn but soon as I hit grass it stops.

My conclusion is the PTO clutches are worn out and need replacing.

So my question is: does anyone know how to remove that clutch pack and repair it? I have searched the internet and not much success on how to get it out of the tractor.

PLEASE don't tell me I have to split that monster. lol

Any help will be much appreciated.

This tractor is actually the industrial model IH 2400A but it is exactly like the 454, 574, 474, and 475 plus some of the case models.

It is the diesel model with the 3 cylinder engine. It has always been a very strong tractor and could mow down anything with my bush hog. HOWEVER, about 3 months ago it began to slow down when I hit heavy grass and now it is to the point where it won't even mow. it will turn but soon as I hit grass it stops.

My conclusion is the PTO clutches are worn out and need replacing.

So my question is: does anyone know how to remove that clutch pack and repair it? I have searched the internet and not much success on how to get it out of the tractor.

PLEASE don't tell me I have to split that monster. lol

Any help will be much appreciated.