Hey everyone. Hoping you can help me out here. I'm jist about done with replacing the Bull Pinion Seals, and put fluid in today. I was about to get about 10 gallons in the transmission, and when I went to put fluid in the hydraulics, I wasn't able to get even 5 gallons in before it over flowed. No what I was expecting. I figured it would suck down, as I had some of the lines off and everything empty. I started it up, and the 3 point was able to raise, but I have to push it down. (Is this normal?) My other issue I have no loader pressure. The loader is a 1501, and has a pipe coming out the front of the tub (see picture). It would seem likely that there may not be enough fluid in yet, but I am very unsure of the priper level, since there is a stack up of fittings at the fill port. I currently have the level to the bottom of what seems to be a tube (about 3 inches down inside the tub itself) at the fill port. I've tried the On/Off knob in both positions and the red lever valve in the pic below in both positions, as well. Any help would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Kerplooey

- Start date

warren woodrow

Member

This is what I believe . The pump on the front right side of tractor is NOT CONSIDERED a front mounted pump . For years I thought it was and thus was

overfilling my transmission as tractor with a true front mounted pump requires more transmission fluid which is separate from the hydraulic fluid in

my tractor . Someone on this forum finally pointed out to me that there is an auxiliary front mounted pump that COULD be purchased and put on my

tractor and that this auxiliary pump is considered the front mounted pump . So.... Right or wrong I consider my tractor not to have a front mounted

pump although mine does have the one shown in your pic which has the suction and pressure hose running from under the seat to the pump.

overfilling my transmission as tractor with a true front mounted pump requires more transmission fluid which is separate from the hydraulic fluid in

my tractor . Someone on this forum finally pointed out to me that there is an auxiliary front mounted pump that COULD be purchased and put on my

tractor and that this auxiliary pump is considered the front mounted pump . So.... Right or wrong I consider my tractor not to have a front mounted

pump although mine does have the one shown in your pic which has the suction and pressure hose running from under the seat to the pump.

Warren, I took to peeling through the Parts Manual page by page last night, amd found the Front Mounted Pump has a special bracket and guard directly on the front of tractor. I am led to believe what is shown in my photo is just the normal installation. My only issue at this point is the proper level in the hydraulics. The book states 5 gallons in the transmission, but it took more than that, about 10 to come out of the level hole (book also states 6" down from filler hole for those with front mounted pumps). Mine had more than 10 in it when I drained it out. The book also states to fill the Hydraulics to the bottom of the filler hole, so I will put more in and see what happens.

Ok, so I brought the fluid level to the bottom of the hole. No change. I did notice that when operating the 3 or up and down, it would pulse in any position other than full down if I kept my foot on it. I raised and lowered it about 20+ times with no response from the loader. I shut it down, and checked for fluid at all hose connections for the loader. There was oil present, so I figured I was making progress. I added more fluid to the top of the standpipe sticking up from the filler. Started it back up and operated the 3 point. No pulsing, but I noticed that if I put some weight on it, I could hold it down. Power steering seems to work well, just rest of hydraulic functions are weak, which is why (I'm assuming) the loader won't work. I'm baffled at this point. Loader was working before I worked on the Pinion Seals. Mayday!

Is it possible to install the suction screen backward? Asking for a friend. I've tried a light percussive adjustment on about everything thinking maybe it was stuck in bypass or something. I've got nothing. Been through all of the books I own. Any suggestions, please throw them his way.

JimB2

Well-known Member

- Location

- Ottawa, Ontario, Canada

Hi, was the hydraulics working before you replaced the Bull pinion seals? Is this tractor new to you?

Did you lift the complete hydraulic housing off the tractor when you replaced the Bull pinion seals? Did you notice a tube going

from the hydraulic housing down into the trans/diff housing? Before you did the seal replacement did the 3pt and load both work

together? It would appear to me looking at your photos the way the loader is connected either the 3pt works or the loader works?

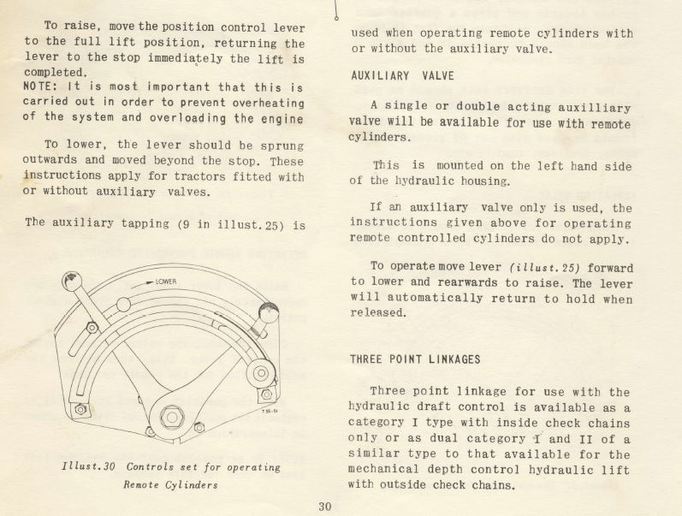

Try this, with the hand lever valve on the loader hose in the open position, move the 3pt lever to 1/2 way up position, turn the

"Isolating Hand wheel Valve" (Right side in front of seat) to OFF then move the 3pt lift lever up about an inch and then try the

loader. If you detect buzzing from the hydraulic housing then move 3pt level back to mid position.

Let us know what happened.

Did you lift the complete hydraulic housing off the tractor when you replaced the Bull pinion seals? Did you notice a tube going

from the hydraulic housing down into the trans/diff housing? Before you did the seal replacement did the 3pt and load both work

together? It would appear to me looking at your photos the way the loader is connected either the 3pt works or the loader works?

Try this, with the hand lever valve on the loader hose in the open position, move the 3pt lever to 1/2 way up position, turn the

"Isolating Hand wheel Valve" (Right side in front of seat) to OFF then move the 3pt lift lever up about an inch and then try the

loader. If you detect buzzing from the hydraulic housing then move 3pt level back to mid position.

Let us know what happened.

(quoted from post at 13:01:38 03/13/19) Hi, was the hydraulics working before you replaced the Bull pinion seals? Is this tractor new to you?

Did you lift the complete hydraulic housing off the tractor when you replaced the Bull pinion seals? Did you notice a tube going

from the hydraulic housing down into the trans/diff housing? Before you did the seal replacement did the 3pt and load both work

together? It would appear to me looking at your photos the way the loader is connected either the 3pt works or the loader works?

move 3pt level back to mid position.

Jimb2,

The hydraulics had been working before I replaced the BP Seals, albeit a little choppy. I had resurfaced the Engine Oil Pump Cover, and just got it running. I used it a about an hour with the loader, and then the loader started to act up, kind of bouncing like it was low on fluid. I parked it in the garage, and got back to a week later to find a puddle of fluid on the floor. It did this twice before I found the pinion seals leaking, so there it sat until a week ago. The Tractor is new to me, and I've been excorcising demons within it since bringing it home. From what I could tell, the 3 point seemed to work before, but I never got to hang an implement on it to notice if it was weak or not. I did lift the the entire housing off the case when I did the seals, but did not notice a tube reaching into the case.. just the spring for the Draft Control. I will try your suggestion and get back to you. I believe I may have a rig that I can plug into the aux and check pressure to the loader, as well.

JimB2

Well-known Member

- Location

- Ottawa, Ontario, Canada

Good, will the loader work now. If not we require some more photos of the loader valve setup and follow the small hydraulic line back from the pump on front right of

engine. I have never seen a 1501 loader hooked up like yours but with enough photos we can sort it out. Also there is an inspection plate under the seat that you can

remove and start tractor at low idle and you should see the hydraulic fluid circulating without any air bubbles or surging.

engine. I have never seen a 1501 loader hooked up like yours but with enough photos we can sort it out. Also there is an inspection plate under the seat that you can

remove and start tractor at low idle and you should see the hydraulic fluid circulating without any air bubbles or surging.

Just some more information; I plugged in a gauge to the hose coming out of the Aux port, which goes into the loader controls. At a medium throttle setting, I got 0 psi whether the Isolater Valve was open or closed. I did not have an adapter large enough to tee into the pump pressure side hose, but I did take it off and turned over the engine. It actually started to my surprise at lowest throttle setting, and I was able to observe fluid flowing out of the hose into a bucket. I was not brave enough nor do I have enough kitty litter to advance the throttle, so I will try and see what I can come up with to check the pump output pressure tomorrow.

BarnyardEngineering

Well-known Member

- Location

- Rochester, NY

I suspect the problem is that you don't have the right combination of valves open/closed as necessary.

This tractor has an open center hydraulic system, and someone has badly butchered it for the loader, hence the need for the valves.

Open center hydraulic systems only work when there's ONE path for the fluid to flow through. Give it a second path, and it won't develop any pressure. A "TEE" is a bad thing anywhere between the valves and pump in an open center hydraulic system.

You won't get any pressure at the pump either due to this even if the pump is perfectly fine.

This tractor has an open center hydraulic system, and someone has badly butchered it for the loader, hence the need for the valves.

Open center hydraulic systems only work when there's ONE path for the fluid to flow through. Give it a second path, and it won't develop any pressure. A "TEE" is a bad thing anywhere between the valves and pump in an open center hydraulic system.

You won't get any pressure at the pump either due to this even if the pump is perfectly fine.

Forgive me for not understanding, but what "TEE" are you talking about? As I understand it, the pipe with the Red Valve on it is typically where an Aux would be tapped in for pressure. ?? Shouldn't the Isolate Valve shut off pressure to the 3 Point and direct it to the Loader? If the system was butchered to allow for the loader installation, what is the proper way to do it? Thanks for any insight.(quoted from post at 06:45:16 03/15/19)

Open center hydraulic systems only work when there's ONE path for the fluid to flow through. Give it a second path, and it won't develop any pressure. A "TEE" is a bad thing anywhere between the valves and pump in an open center hydraulic system.

JimB2

Well-known Member

- Location

- Ottawa, Ontario, Canada

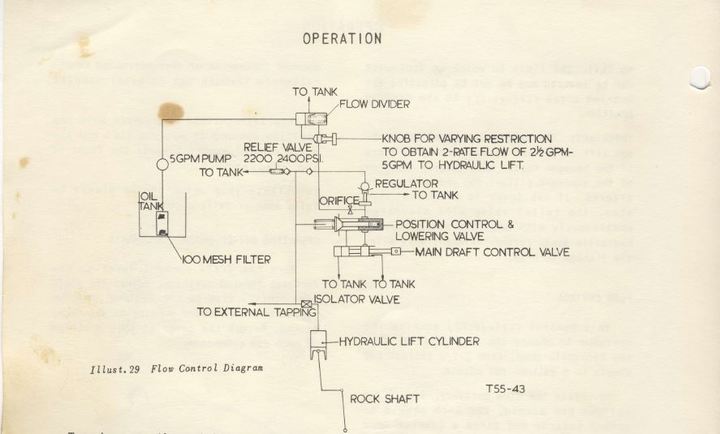

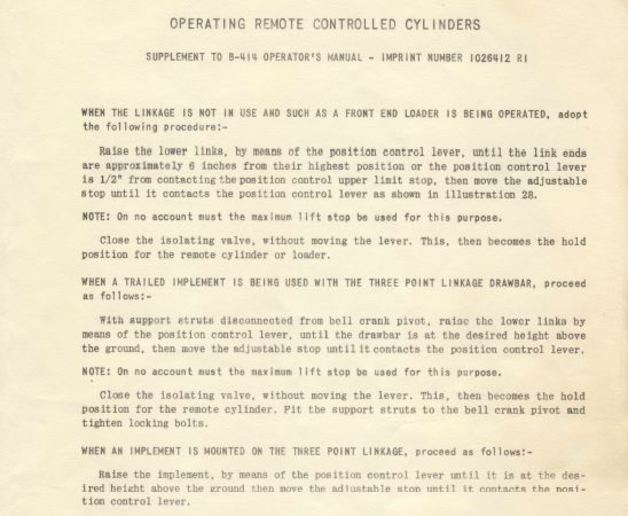

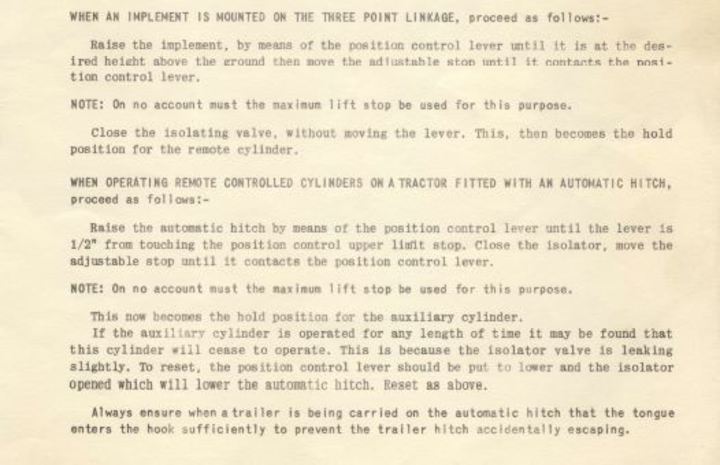

Hi, before flow will come out the Aux port the 3pt lift lever has to be in the proper position.

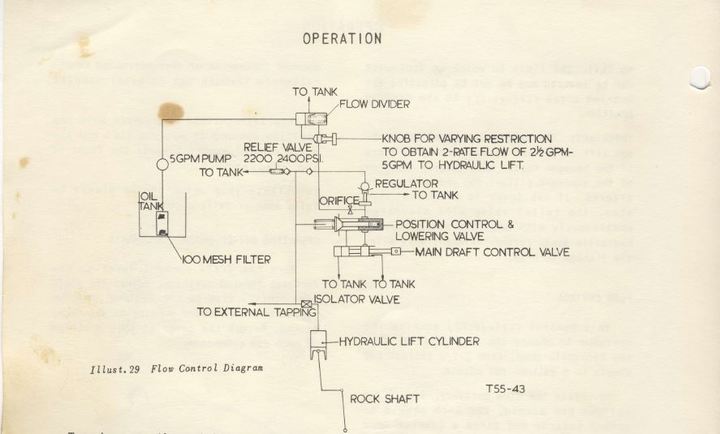

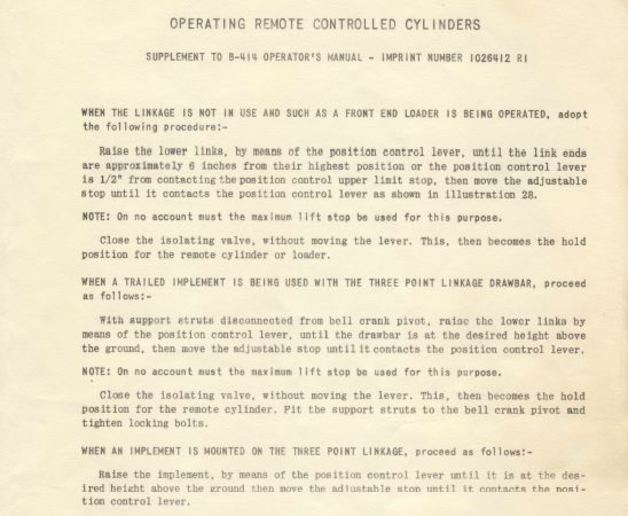

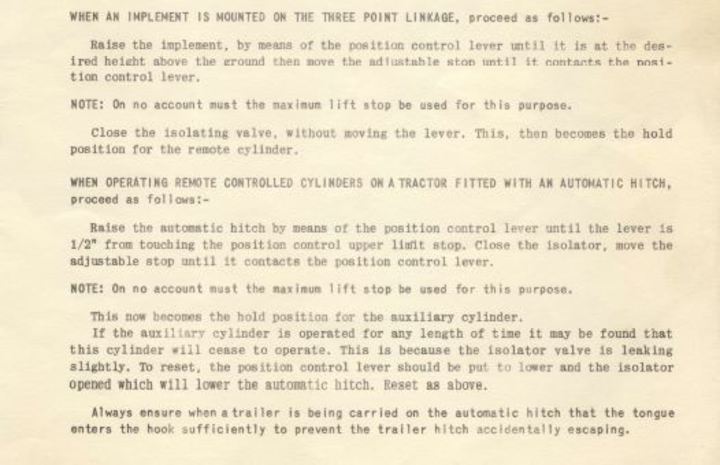

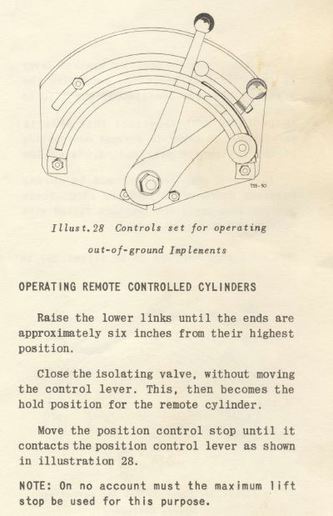

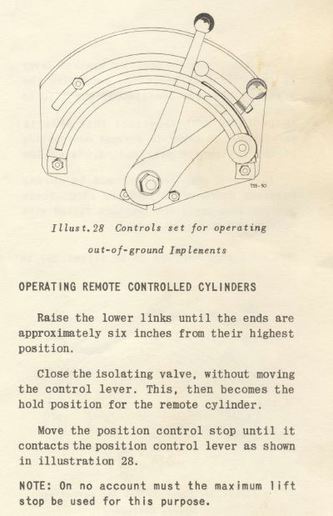

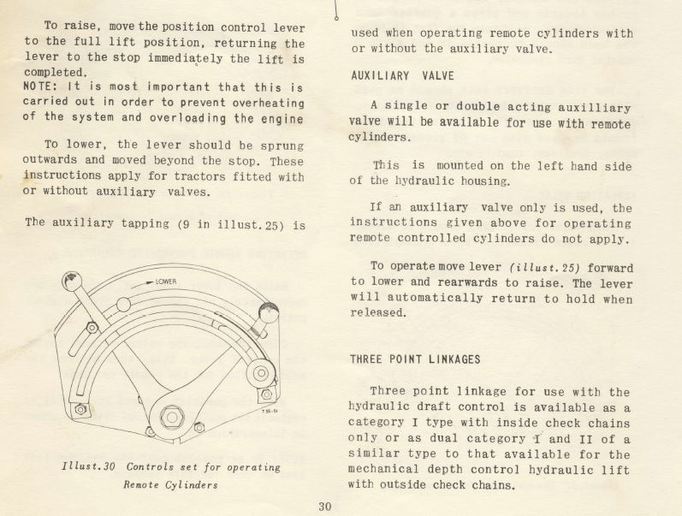

I am attaching the page from my B414 Operator's Manual(your 444 in a grandson of the B414). Unfortunately this site does not

allow pdf documents so I had to snip it into multiple jpgs.

I agree with BarnYardE that someone made a mess.

Hopefully after you read the Remote Cylinder Operating instructions it will help sort out your problem.

Basically the 3pt lift lever will have to remain locked in the UP position to have continuous flow out of the Aux port.

I am attaching the page from my B414 Operator's Manual(your 444 in a grandson of the B414). Unfortunately this site does not

allow pdf documents so I had to snip it into multiple jpgs.

I agree with BarnYardE that someone made a mess.

Hopefully after you read the Remote Cylinder Operating instructions it will help sort out your problem.

Basically the 3pt lift lever will have to remain locked in the UP position to have continuous flow out of the Aux port.

Jimb2, THANK YOU!! The 444 manual has a page with similar images, but does not break it down like the 414 manual does. Using what you gave me, I was able to figure out the correct combo; 3 point down, Isolate closed, then position lever back, and loader came alive. I have some things to figure out yet, but I hope I that I will have use of both at one time. Still trying to figure out why the handle with the red valve is there. Thanks to everyone who helped me with this. I was about making myself crazy with it. I will see what other anomalies with this thread I can answer and post them below.

JimB2

Well-known Member

- Location

- Ottawa, Ontario, Canada

Hi, great news, I have spent a lot of time in the seat of B414, 434 and 384 with 1501 loader and later with the newer 1550

loader. We never had a 444 but neighbor next farm to east had one with 1550 loader.

To be able to use the loader and 3pt you have to modify the loader plumbing.

It is more difficult on your 444 because it is a USA assembled unit with both the suction line and the pressure line connecting

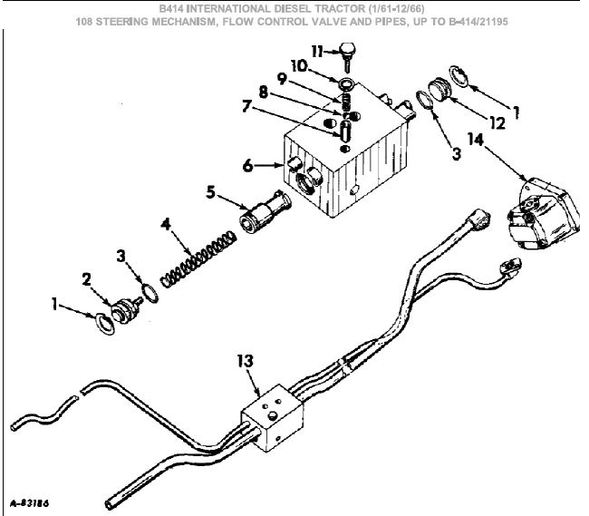

to a block that connects to the hydraulic pump. Also the high pressure line from the hydraulic pump has a hydraulic splitter

block back by the clutch housing that splits out 3 GPM for the PS. The UK build units had two hydraulic pumps, one stacked on

the rear of the other and one ran 3pt and the other ran PS.

To make the 3pt and loader usable on your 444 would require connecting the loader hydraulic control in hose (the one that is

connected to the Aux port now) to the small high pressure line out of the splitter block and the loader hydraulic control out

hose (center right side of loader control, now going back to filler plug) to the small hi pressure line at the front of the seat

just above the transmission cover. The dump line that connects to bottom of loader control will remain going into hydraulic

filler plug. This configuration will allow 3pt and loader to operate together but if you pull loader control valve lever and 3pt

lever at the same time the loader will go first and as soon as you release loader valve 3pt will lift.

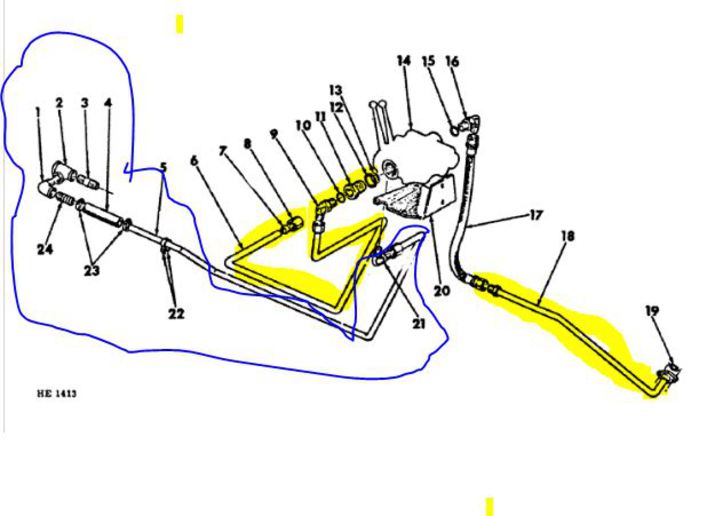

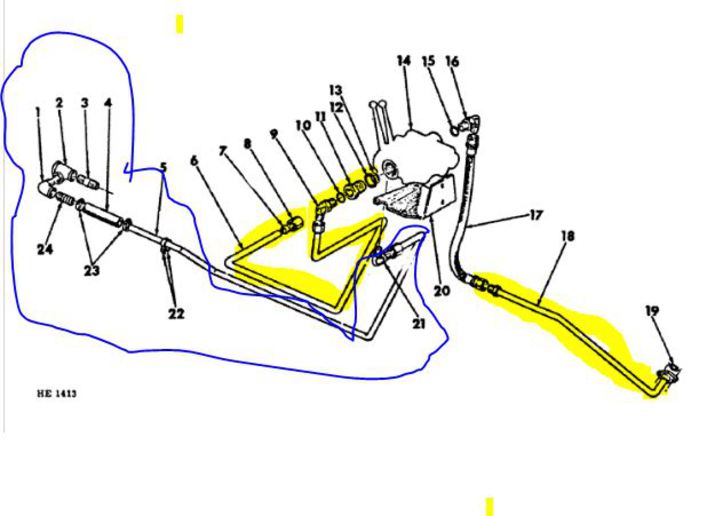

I have included a couple of photos, one of proper loader control vale connection, parts in yellow is the ones you would have to

add, the blue parts you already have connected. The item #18 and 19 you could buy from CIH but the one shown goes directly to

the pump, yours would have to connect to high pressure line out of the splitter block. I don't know if the lines are screwed

into the splitter block or welded. Here in Canada we always had the UK build models.

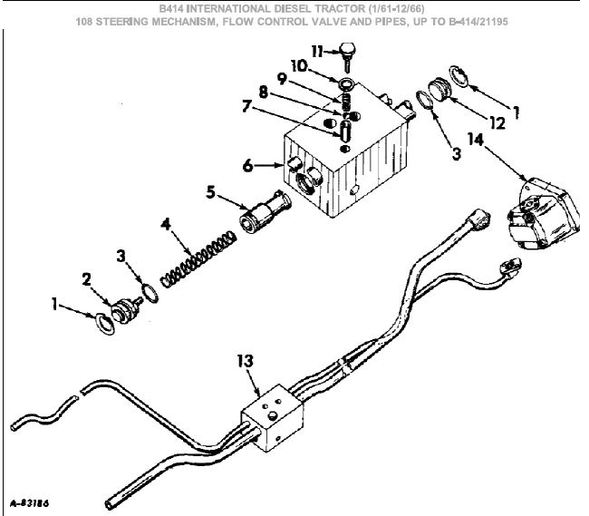

The other photo is of a typical PS splitter block from CIH parts.

Hope your 444 works well for you.

loader. We never had a 444 but neighbor next farm to east had one with 1550 loader.

To be able to use the loader and 3pt you have to modify the loader plumbing.

It is more difficult on your 444 because it is a USA assembled unit with both the suction line and the pressure line connecting

to a block that connects to the hydraulic pump. Also the high pressure line from the hydraulic pump has a hydraulic splitter

block back by the clutch housing that splits out 3 GPM for the PS. The UK build units had two hydraulic pumps, one stacked on

the rear of the other and one ran 3pt and the other ran PS.

To make the 3pt and loader usable on your 444 would require connecting the loader hydraulic control in hose (the one that is

connected to the Aux port now) to the small high pressure line out of the splitter block and the loader hydraulic control out

hose (center right side of loader control, now going back to filler plug) to the small hi pressure line at the front of the seat

just above the transmission cover. The dump line that connects to bottom of loader control will remain going into hydraulic

filler plug. This configuration will allow 3pt and loader to operate together but if you pull loader control valve lever and 3pt

lever at the same time the loader will go first and as soon as you release loader valve 3pt will lift.

I have included a couple of photos, one of proper loader control vale connection, parts in yellow is the ones you would have to

add, the blue parts you already have connected. The item #18 and 19 you could buy from CIH but the one shown goes directly to

the pump, yours would have to connect to high pressure line out of the splitter block. I don't know if the lines are screwed

into the splitter block or welded. Here in Canada we always had the UK build models.

The other photo is of a typical PS splitter block from CIH parts.

Hope your 444 works well for you.

JimB2,

Thank you for your continued support! In your explanation, you stated that I would need to connect the loader hydraulic control in hose that is connected to the Aux Port to the small high pressure line out of the splitter block. Please see the photo below. Do you mean the small line shaped like a question mark? Reason I ask is it is tapped into the Hyd Pump Suction Line, which I wouldn't think to be High Pressure. Also the loader hydraulic control out hose would have to go to the small hi pressure line at the front of the seat just above the transmission cover. Is that the one directly behind the shifter (shown in the second pic of this thread)? That pipe also goes to the PS Block, which I have labeled below. Forgive me for not understanding... it just doesn't make sense to me as to why both would connected to High Pressure.

Thank you for your continued support! In your explanation, you stated that I would need to connect the loader hydraulic control in hose that is connected to the Aux Port to the small high pressure line out of the splitter block. Please see the photo below. Do you mean the small line shaped like a question mark? Reason I ask is it is tapped into the Hyd Pump Suction Line, which I wouldn't think to be High Pressure. Also the loader hydraulic control out hose would have to go to the small hi pressure line at the front of the seat just above the transmission cover. Is that the one directly behind the shifter (shown in the second pic of this thread)? That pipe also goes to the PS Block, which I have labeled below. Forgive me for not understanding... it just doesn't make sense to me as to why both would connected to High Pressure.

JimB2

Well-known Member

- Location

- Ottawa, Ontario, Canada

Hi, not the ? line but remove the "Pressure to Hyd Head" line and connect the Loader valve high pressure In port Hyd line to

here.

Connect the Loader valve Out port to the Hyd In Port on the Hyd Head in front of the seat. This is where the line that you have

labelled "Pressure to Hyd Head" should go. I took your photos and put a blue line around the Hyd lines to connect the Loader

Value into.

Third photo is of a 444 with a similar Loader control valve as yours except it does not have a dump Hyd line going to the fill

plug behind the seat. The blue line is high pressure in from splitter block to In port on loader valve and black line is loader

valve Out port to high pressure In port of Hyd Head in front of seat. In this photo it would appear that the installer just took

the Hyd line off the splitter block and bent it out so that he could connect a hyd hose. Not ideal but it works. Usual method is

to shorten the steel line and put a new Hyd fitting on it or run a Hyd hose directly to the In port of Hyd Head but it is a

little difficult to get the Hyd hose to fit next the trans cover.

Theory, you 444 is an "Open Center" hydraulic system, meaning that the hyd oil is constantly flowing in a loop and when you pull

a control valve it diverts this flow to the hyd cylinder. This system is like an series electrical system. Newer modern tractors

use "Closed Center" Hyd system where there is constant pressure on all valves and the pressure is regulated by the pump. This is

like the water system in your house.

So for your 444 that is the reason you would connect the Splitter Block "Pressure to Hyd Head" port to the In port of Loader

valve and then the Loader valve Out port to the In port of "Hyd Head". The free flowing loop of Hyd oil must be maintained or

damage to the Hyd pump will occur. On the third photo I red circled the relief valve in the loader control valve, this to

protect the pump. If you were to take the loader off the tractor including the loader control valve, you would have to connect

the Hyd hoses from the loader control value In port to the Out port together to maintain the Hyd oil flow loop.

Hope this makes sense to you, if not post more questions.

JimB

here.

Connect the Loader valve Out port to the Hyd In Port on the Hyd Head in front of the seat. This is where the line that you have

labelled "Pressure to Hyd Head" should go. I took your photos and put a blue line around the Hyd lines to connect the Loader

Value into.

Third photo is of a 444 with a similar Loader control valve as yours except it does not have a dump Hyd line going to the fill

plug behind the seat. The blue line is high pressure in from splitter block to In port on loader valve and black line is loader

valve Out port to high pressure In port of Hyd Head in front of seat. In this photo it would appear that the installer just took

the Hyd line off the splitter block and bent it out so that he could connect a hyd hose. Not ideal but it works. Usual method is

to shorten the steel line and put a new Hyd fitting on it or run a Hyd hose directly to the In port of Hyd Head but it is a

little difficult to get the Hyd hose to fit next the trans cover.

Theory, you 444 is an "Open Center" hydraulic system, meaning that the hyd oil is constantly flowing in a loop and when you pull

a control valve it diverts this flow to the hyd cylinder. This system is like an series electrical system. Newer modern tractors

use "Closed Center" Hyd system where there is constant pressure on all valves and the pressure is regulated by the pump. This is

like the water system in your house.

So for your 444 that is the reason you would connect the Splitter Block "Pressure to Hyd Head" port to the In port of Loader

valve and then the Loader valve Out port to the In port of "Hyd Head". The free flowing loop of Hyd oil must be maintained or

damage to the Hyd pump will occur. On the third photo I red circled the relief valve in the loader control valve, this to

protect the pump. If you were to take the loader off the tractor including the loader control valve, you would have to connect

the Hyd hoses from the loader control value In port to the Out port together to maintain the Hyd oil flow loop.

Hope this makes sense to you, if not post more questions.

JimB

BarnyardEngineering

Well-known Member

- Location

- Rochester, NY

The TEE I was talking about was the TEE you were going to put in to take pressure, along with the numerous other TEEs that were shown in your pictures.

If done properly, everything should just work. You should not need to do the hokey-pokey with a bunch of valves and have to choose between loader, 3pt, and/or whatever else. How that's done on a 444, I can't tell you because I'm not familiar with that tractor, but it's not impossible. There's no magic to hydraulics.

However, don't look a gift horse in the mouth. You figured out how to make it work, and that's a GREAT thing. "It works" is 99% of the way there. Having it neat and elegant, not a priority. The other thing is it will likely cost you a few hundred dollars in hoses... Replumbing is only a last resort if you couldn't figure out how to make it work.

If done properly, everything should just work. You should not need to do the hokey-pokey with a bunch of valves and have to choose between loader, 3pt, and/or whatever else. How that's done on a 444, I can't tell you because I'm not familiar with that tractor, but it's not impossible. There's no magic to hydraulics.

However, don't look a gift horse in the mouth. You figured out how to make it work, and that's a GREAT thing. "It works" is 99% of the way there. Having it neat and elegant, not a priority. The other thing is it will likely cost you a few hundred dollars in hoses... Replumbing is only a last resort if you couldn't figure out how to make it work.

I never stated anything about installing a "TEE" anywhere, thus my confusion. I was installing a terminating pressure gauge in the Aux port to check for pressure, which would not overload the pump.

I agree that there is no magic to hydraulics and I would never "look a gift horse in the mouth". I am thrilled that I don't have to replace any parts due to wear or damage. However, this is no trailer queen, either. It will be put to work, likely on a daily basis. I don't have time or the patience to be trying to do a job with something that is not correct. For the time to make 2 lines, it would be done properly and done. Who wouldn't want their machine to be working as intended? I mean, that's why we're all here, right?

I agree that there is no magic to hydraulics and I would never "look a gift horse in the mouth". I am thrilled that I don't have to replace any parts due to wear or damage. However, this is no trailer queen, either. It will be put to work, likely on a daily basis. I don't have time or the patience to be trying to do a job with something that is not correct. For the time to make 2 lines, it would be done properly and done. Who wouldn't want their machine to be working as intended? I mean, that's why we're all here, right?

Similar threads

- Replies

- 10

- Views

- 407

- Replies

- 3

- Views

- 218

- Replies

- 0

- Views

- 66

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy