Young Mechanic

Member

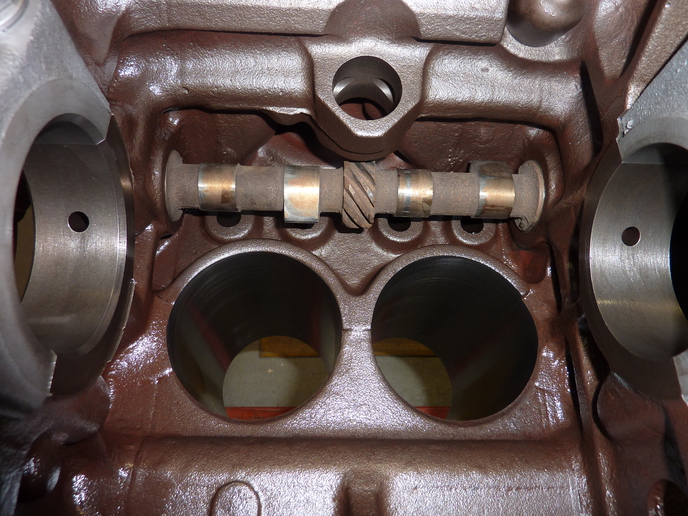

So here's the deal, got a customers tractor in, restored as some would call it, needs a few things. Engine is not putting any oil up to the rockers, so I pulled the pan pick up screen was clean, disassembled oil pump, spring was broke, gears were in spec, pump cover was not mating up good, got new spring, got cover sealed up good, reassembled and changed filter, oil pressure got better but no oil up to rockers. Next, took rockers off hole was open and clean. Next took head off, port was open and clean, and to my surprise the head gasket was on correct so the hole in the gasket was lined up with the hole in the block and head. Cranked engine with head off still no oil coming out of port to the rockers. Next I pressurized the port with air and it sounds like it is just leaking into the crank case, doesn't wiggle the gauge. Took plug out of oil galley on side of block blew air in that, it then wiggles the gauge and blows through the pump, I can hear it churning the oil in the pan but still no oil or air comes out of port to the rockers. I guess my question is does anyone know if there is a oil galley plug inside the crank case that someone maybe didn't put back in? What else could it be? ANY HELP WOULD BE APPRECIATED.