I have an interesting problem on my recently bought JD450 dozer: The machine starts right up, doesn't skip a beat for about 5-10 minutes. Then for no reason at all, it just stops running. And won't restart either. Even after returning an hour later.. no/go. If I return to the machine the next day, it will start right up, then the whole situation manifests itself again.. I thought that it may have too low in fuel, so I added about 5 gallons, since the fuel level barely showed on the tank dip-stick. Didn't help. One of the return lines has a cracked rubber T boot and dripping water on the left hand side of the block, but I don't think this would be enough to stall the engine. Any thoughts??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter oneliner

- Start date

Jim.ME

Well-known Member

- Location

- central ME

5 gallons should keep it running. That said: If the tank is that low it would be a good time to at least look in it and see if you spot any foreign material in it. You didn't say if it is a straight 450 or a later letter model 450. Some had screens in the bottom of the fuel tank, if yours does it would be a good time to drain the tank and check/clean it. When was/were the fuel filter/filters last changed? Running the tank that low increases the possibility of the filter(s) plugging as any debris in the tank is likely to be more concentrated in the fuel. Pull the little cover, held with two screws, from the side of the injection pump and see if you see any pieces that look like mouse turds behind it. Remove the return line fitting/check valve from the fuel pump and see if there are any of those pieces in the check valve. Seeing those pieces in the window and/or check valve is a sign the pellethane ring is coming apart in the pump. The pieces plug the return line and performance will suffer and the engine may stall; as the return to tank must be clear to flow. When it stalls try just loosening the screws holding the little cover to let it leak and see if it starts.

I hope the cracked return line tee boot is not the source of the water dripping on the left side of the block.

If you don't know your model for certain, post the full serial number and someone will decode it for you. Then get a proper set of manuals for it if you don't have them. You can access the free on line John Deere parts catalogs at https://jdparts.deere.com/servlet/c...ountrySelected&country=US&language=19. You need to be sure you have the proper model and your serial number as there are serial number breaks for some arrangements.

I hope the cracked return line tee boot is not the source of the water dripping on the left side of the block.

If you don't know your model for certain, post the full serial number and someone will decode it for you. Then get a proper set of manuals for it if you don't have them. You can access the free on line John Deere parts catalogs at https://jdparts.deere.com/servlet/c...ountrySelected&country=US&language=19. You need to be sure you have the proper model and your serial number as there are serial number breaks for some arrangements.

Thank you for taking the time in answering my question, Jim.me. It is a straight 450. No letters following. I do believe that the filters were "recently changed", but that along with I had it running a year ago, and it ran fine when parked leads me to believe that it has been quite some time since they were both replaced!!! But yes, it would be a perfect time to start going through the filters, starting with the tank, and moving forward. The air release at the top of the filter housings do release air, so I thought that they were doing their job in filtering the fuel prior to going to the injector pump. Which could only be the other way around: unfiltered fuel enters the middle, and filtered fuel out to the sides of the element..But anyway, I will update my post once I start going through the machine. Thanks again. Hopefully that is the culprit!!!

(quoted from post at 03:16:38 08/05/19) 5 gallons should keep it running. That said: If the tank is that low it would be a good time to at least look in it and see if you spot any foreign material in it. You didn't say if it is a straight 450 or a later letter model 450. Some had screens in the bottom of the fuel tank, if yours does it would be a good time to drain the tank and check/clean it. When was/were the fuel filter/filters last changed? Running the tank that low increases the possibility of the filter(s) plugging as any debris in the tank is likely to be more concentrated in the fuel. Pull the little cover, held with two screws, from the side of the injection pump and see if you see any pieces that look like mouse turds behind it. Remove the return line fitting/check valve from the fuel pump and see if there are any of those pieces in the check valve. Seeing those pieces in the window and/or check valve is a sign the pellethane ring is coming apart in the pump. The pieces plug the return line and performance will suffer and the engine may stall; as the return to tank must be clear to flow. When it stalls try just loosening the screws holding the little cover to let it leak and see if it starts.

I hope the cracked return line tee boot is not the source of the water dripping on the left side of the block.

If you don't know your model for certain, post the full serial number and someone will decode it for you. Then get a proper set of manuals for it if you don't have them. You can access the free on line John Deere parts catalogs at https://jdparts.deere.com/servlet/c...ountrySelected&country=US&language=19. You need to be sure you have the proper model and your serial number as there are serial number breaks for some arrangements.

Jim.ME

Well-known Member

- Location

- central ME

If you have the two filter element housing used on the early 450s the fuel flow is as in the attached photo. Down the center of the element, through the filter media, then out to the next filter or injection pump.

[/img]

Using the lever on the side of the transfer pump to fill the filters; once the filters are full you should not get air from the bleeder screws. If you continue to get air, you have a leak some where in a line or the transfer pump. Bleed the filter nearest the transfer pump first until you get a clear fuel flow, then do the second one.

If it set for a year you may have condensation and?or algae issues. You don't say where you are located but wide temperature swings and an almost empty tank can be a recipe for a lot of internal tank condensation. You may do well to change the filters after checking the tank.

[/img]

Using the lever on the side of the transfer pump to fill the filters; once the filters are full you should not get air from the bleeder screws. If you continue to get air, you have a leak some where in a line or the transfer pump. Bleed the filter nearest the transfer pump first until you get a clear fuel flow, then do the second one.

If it set for a year you may have condensation and?or algae issues. You don't say where you are located but wide temperature swings and an almost empty tank can be a recipe for a lot of internal tank condensation. You may do well to change the filters after checking the tank.

My first suspect would be the fuel fitting at the bottom of the fuel tank. Has a tiny hole around 1/8" for fuel to flow and gets plugged very

easy. We had many older 350s and 450s dies because of that and added a small diameter fuel strainer attached to the fuel valve to prevent it

from plugging again. We had many that did just as you describe.

A failed pellathane dampener inside the injection pump (DB or JDB only) can cause similar issues except after it quits - it will restart a

few minutes later. My vote is a plugged valve at the bottom of the tank.

easy. We had many older 350s and 450s dies because of that and added a small diameter fuel strainer attached to the fuel valve to prevent it

from plugging again. We had many that did just as you describe.

A failed pellathane dampener inside the injection pump (DB or JDB only) can cause similar issues except after it quits - it will restart a

few minutes later. My vote is a plugged valve at the bottom of the tank.

Is it difficult to replace the pellethane ring? I have yet to take an injection pump apart

quote="JDEM"](quoted from post at 12:27:03 08/05/19) My first suspect would be the fuel fitting at the bottom of the fuel tank. Has a tiny hole around 1/8" for fuel to flow and gets plugged very

easy. We had many older 350s and 450s dies because of that and added a small diameter fuel strainer attached to the fuel valve to prevent it

from plugging again. We had many that did just as you describe.

A failed pellathane dampener inside the injection pump (DB or JDB only) can cause similar issues except after it quits - it will restart a

few minutes later. My vote is a plugged valve at the bottom of the tank.[/quote]

quote="JDEM"](quoted from post at 12:27:03 08/05/19) My first suspect would be the fuel fitting at the bottom of the fuel tank. Has a tiny hole around 1/8" for fuel to flow and gets plugged very

easy. We had many older 350s and 450s dies because of that and added a small diameter fuel strainer attached to the fuel valve to prevent it

from plugging again. We had many that did just as you describe.

A failed pellathane dampener inside the injection pump (DB or JDB only) can cause similar issues except after it quits - it will restart a

few minutes later. My vote is a plugged valve at the bottom of the tank.[/quote]

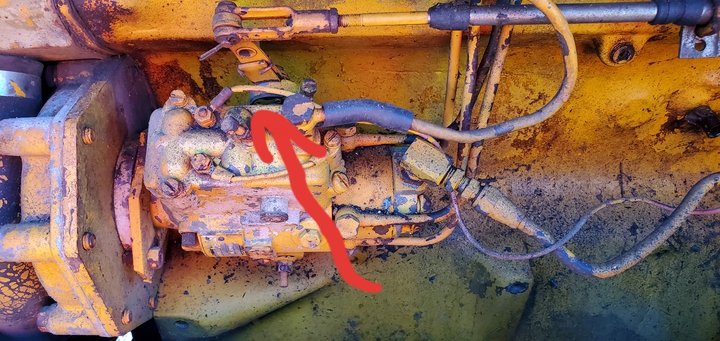

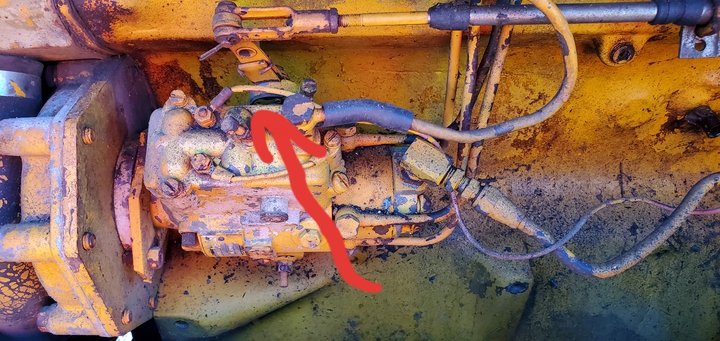

Some 450s used small round injection pumps that have no pellathane ring inside to fail. Parts for those pumps became unavailable in the

eary 80s and Deere sold kits to convert them with later style pumps. So, I have no idea what you have. Here is a photo from another poster

here with a conversion pump on his Deere crawler. If you pump looks like the one in this photo, then you DO have the plastic/pellathane

ring that often fails. To replace it? With the pump off on the bench (or tailgate of your truck), it takes about an hour to replace the

ring and install all new seals in the pump. $25 in parts. Requires one special tool that costs around $10 if you can find one anymore.

Note - that is one hour IF you have experience. If not and you are using the repair manual - it might take you half a day. No big mystery

inside. It is just two hydraulic pumps coupled together with a flyweight governor inside. There is one bolt that has to be removed that

uses a 6 tooth male Bristol wrench. Just about every Deere of that vintage I ever worked on has that 6 tooth bolt head. Other makes of

tractors sometimes had a more common Allen head instead.

Note that IF that ring inside the pump failed (assuming you have a JDB or DB pump) . . the inside of the injection pump reaches too high a

pressure because return fuel cannot get out fast enough. When that inside pressure exceeds charge pressure - it acts like it had run out

of fuel. This happens because little pieces of that plastic ring get stuck in the return fuel circuit and stop fuel from exiting the pump.

Look at this other poster's photo. Is this what you have?

eary 80s and Deere sold kits to convert them with later style pumps. So, I have no idea what you have. Here is a photo from another poster

here with a conversion pump on his Deere crawler. If you pump looks like the one in this photo, then you DO have the plastic/pellathane

ring that often fails. To replace it? With the pump off on the bench (or tailgate of your truck), it takes about an hour to replace the

ring and install all new seals in the pump. $25 in parts. Requires one special tool that costs around $10 if you can find one anymore.

Note - that is one hour IF you have experience. If not and you are using the repair manual - it might take you half a day. No big mystery

inside. It is just two hydraulic pumps coupled together with a flyweight governor inside. There is one bolt that has to be removed that

uses a 6 tooth male Bristol wrench. Just about every Deere of that vintage I ever worked on has that 6 tooth bolt head. Other makes of

tractors sometimes had a more common Allen head instead.

Note that IF that ring inside the pump failed (assuming you have a JDB or DB pump) . . the inside of the injection pump reaches too high a

pressure because return fuel cannot get out fast enough. When that inside pressure exceeds charge pressure - it acts like it had run out

of fuel. This happens because little pieces of that plastic ring get stuck in the return fuel circuit and stop fuel from exiting the pump.

Look at this other poster's photo. Is this what you have?

Oh boy! I have to go and check. With the T boot leaking on the bloc, everything is coated with a nice thick film of thick dust!!! I have to pressure wash the engine once I replace the T boot, and at that point, I will be able to see what I have. Also want to find the inspection plate to see if the "mouse turd" fragments are present. Didn't want to do so with all of the crap on the injection pump.

(quoted from post at 16:14:53 08/07/19) I think we are talking about the

same injection pump. Although grimy,

here's what I have (no cut off

wire):

buickanddeere

Well-known Member

(quoted from post at 22:51:21 08/04/19) I have an interesting problem on my recently bought JD450 dozer: The machine starts right up, doesn't skip a beat for about 5-10 minutes. Then for no reason at all, it just stops running. And won't restart either. Even after returning an hour later.. no/go. If I return to the machine the next day, it will start right up, then the whole situation manifests itself again.. I thought that it may have too low in fuel, so I added about 5 gallons, since the fuel level barely showed on the tank dip-stick. Didn't help. One of the return lines has a cracked rubber T boot and dripping water on the left hand side of the block, but I don't think this would be enough to stall the engine. Any thoughts??

Had the same thing happen to my JD 1640 tractor . The boys ran it out of fuel and poured 5 gallons into the empty tank. . This stirred up 20+ years of debris in the bottom sump of the tank.

The trash would plug new filters in minutes. Had to remove the tanks drain valve and flush the system. Blew and bunch of trash from the fuel lines and primary pump .

Ran well for a month and then the primary pump failed .

An old injection pump can also plug from a deteriorating drive ring. This will plug the return line check ball . If so, have the drive ring replaced prior to paying for a total pump failure .

I just posted a pick of my pump. Looks different from what you also posted. What do you think> Mine seems different, but I have no idea as to what the serial # might be. I will be pressure washing it in a few days so maybe I will be in luck and go in the direction that you mention.

Jim.ME

Well-known Member

- Location

- central ME

The arrow points to the tag that will have the info to ID your pump for certain. To me it looks like a DB series with a mechanical shutoff.

Here is a link to a Stanadyne manual on line that will give you insight into the pump.

http://www.stanadyne.com/dealerportal/ssi/english/Product Manual/99523.pdf

I live in Up State NY, close to Lake Ontario. So hot summers, nd cold winters. Machine was most likely left outdoors for the majority if its life.

One thing that I am stupefied of, is that when I bought the machine, I noticed that one of the filters, the right hand side one, was upside down. Donno know why, and I don't believe that it is not meant to be installed in that manner. Fuel flow, as per your diagram, is the same for both can filters.

Any idea??

One thing that I am stupefied of, is that when I bought the machine, I noticed that one of the filters, the right hand side one, was upside down. Donno know why, and I don't believe that it is not meant to be installed in that manner. Fuel flow, as per your diagram, is the same for both can filters.

Any idea??

Jim.ME

Well-known Member

- Location

- central ME

(quoted from post at 08:42:00 08/12/19) I live in Up State NY, close to Lake Ontario. So hot summers, nd cold winters. Machine was most likely left outdoors for the majority if its life.

One thing that I am stupefied of, is that when I bought the machine, I noticed that one of the filters, the right hand side one, was upside down. Donno know why, and I don't believe that it is not meant to be installed in that manner. Fuel flow, as per your diagram, is the same for both can filters.

Any idea??

I wouldn't think it would seal upside down. Maybe it is labelled upside down compared to the other one. Post a photo of the filters. I think you should change the filters and bleed it before you start going too deep into it. The filters could be plugging due to sediment stirred up in the tank with fuel that low.

I've seen a lot worse as far as grim.

Well, I thought I had the problem licked once I noticed the the screws on top of the lift pump with loose by 1/4 turn. That helped to keep the machine running for approx. 15 minutes at a time. Enough to be able to load & unload it on a trailer for transport back home. But even after replacing the lift pump, and both fuel filters, it will run for another short length of time, and stall out. I blew compressed air from the fuel line of the lift pump back to the fuel tank too. Just won't stay running. I also found that the fittings on the old lift pump didn't need much effort to unscrew. Thoughts??

Jim.ME

Well-known Member

- Location

- central ME

Is the fuel tank still as low as you posted earlier? If so have you taken a good flashlight and looked inside it to check condition and see if anything is floating around inside it? What brand fuel filters did you install? After it stalls you don't have to bleed the filters or anything else for it to start (it just has to set), is that correct? Does it fire of immediately when it restarts, or does it have to crank for a bit? Have you tried running it with the cap off the fuel tank? Have you blown air through the return line (from after the #4 injector connection) to the tank?

Do you have the service manual (JD # SM2064) for your crawler?

Do you have the service manual (JD # SM2064) for your crawler?

All excellent points. I filled up the tank with about 15 gallons of fresh fuel and replaced the filters with JD replacements. I don't have to bleed the filters between stalls, but do I pump up the finger prime lever on the lift pump, and that usually keeps it going for a while. Same duration though. Cant see the bottom of the tank now since its got quite a bit of fuel in it. I tried to look into the tank at night, but no luck.

As per your post, I should check the following:

run it w/o the fill cap

blow air through the return line

It starts immediately after it sits, but needs to crank over several times if I try after it stalls..

As per your post, I should check the following:

run it w/o the fill cap

blow air through the return line

It starts immediately after it sits, but needs to crank over several times if I try after it stalls..

Jim.ME

Well-known Member

- Location

- central ME

I ask again: Do you have the service manual (JD # SM2064) for your crawler?

Having the Service manual, and the Operator's Manual for machines you own is money well spent in my opinion. A manual won't answer all questions, but from them you can read and see how systems work. There many be diagnostic points we may miss in these discussions.

As for my saying look in the tank; I have had a couple machines I chased for similar symptoms. I found foreign material in them that floated over the suction outlet in the tank during operation then drifted away from it when the suction was gone (engine stalled). One was a plastic sandwich bag. Blowing back can clear the suction but the blockage can return if it is floating around in there.

Having the Service manual, and the Operator's Manual for machines you own is money well spent in my opinion. A manual won't answer all questions, but from them you can read and see how systems work. There many be diagnostic points we may miss in these discussions.

As for my saying look in the tank; I have had a couple machines I chased for similar symptoms. I found foreign material in them that floated over the suction outlet in the tank during operation then drifted away from it when the suction was gone (engine stalled). One was a plastic sandwich bag. Blowing back can clear the suction but the blockage can return if it is floating around in there.

My first order of business will be to drain the tank completely, of about 15 gal. of fuel, and remove or replace some old funky shut off vale that dosnt seem to be functional any more.

Oh, and no, I don't have the service manual.. But thanks to you, in giving me the part number, I will be ordering one shortly!

Oh, and no, I don't have the service manual.. But thanks to you, in giving me the part number, I will be ordering one shortly!

Didn't find anything interesting in the tank. Drained over 20 gallons, unscrewed the return line and outlet, blew air into both. Nothing. Bottom of tank clean. Both lines are installed to the outside wall of the tank, not the bottom, as you would expect. I did find a 4" length of rubber fuel line joining the supply line of the injection pump, joined together though. I replaced the rubber line, but still, ran the machine for approx. 10 minutes, and it quite once more. Crap!!! I removed the small plate that is installed on the injection pump, to the right of the ID plate, to see if it had the "mouse turd" issue, but nothing there either. Approx. a cup of fuel drained out though. Not sure if there should be any fuel on this side of the pump.. Man, just don't know where to look next!!!

I think I have the issue licked!!! After looking at Jim B's diagram, I went to my local JD dealer and purchased the said check valve (now $30) and installed the rather non-impressive part onto my injection pump. I had to make a new fuel line, because the old one did not release the cap, and twisted the line right up. I also blew out the return line from the #4 injector back to the tank, added some fuel, and voila!! I had it idling for an hour without a skip. Although not in operation mode, previously, I could not keep it idling for more than 5-10 minutes!!!

Thank you very much to those who gave me insight on how to troubleshoot the fuel system. You are all a great help!!

Thank you very much to those who gave me insight on how to troubleshoot the fuel system. You are all a great help!!

Similar threads

- Replies

- 28

- Views

- 4K

- Replies

- 5

- Views

- 834

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy