I was born in 39 and at your age I had racked up many hours running dad’s well used 38 C Case which stayed in the family for about 6 decades because I rescued it from the junk man. Back then in the late 40s and 50s, I dreamed of dad and us having a DC but that never happened. The DC became a sentimental favorite of mine because the C was a good tractor and quite similar to the DC.

So for sentimental reasons in the 80s and 90s, I rescued a total of six 49-53 DCs from the junk man and put them back into good running condition. My goal (hobby at the time) was to preserve sentimental DCs. There is no money to be made persevering DCs. Hobbies are good for various reasons but many hobbies are money pits. What are your goals toward your free DC and the other two?

Your DC is a hodge-podge of model years which is not good for complete restorations and good resale. Your engine is apparently a 45 model. (subtract 4 from the first two serial # digits to get the model year so 49-4 is 45. ) The fenders are pre-52 because they do not have ribs on the inside. A good news is your fenders are in good condition. The ribbed fenders had a very serious rust problem down low at their seam and are very difficult to fix.

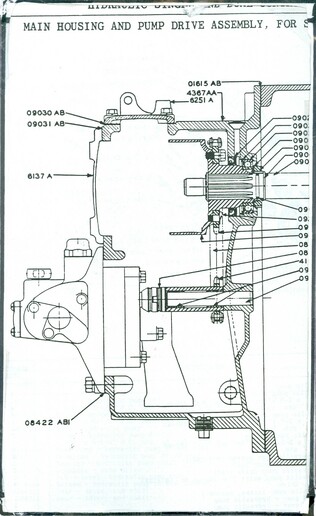

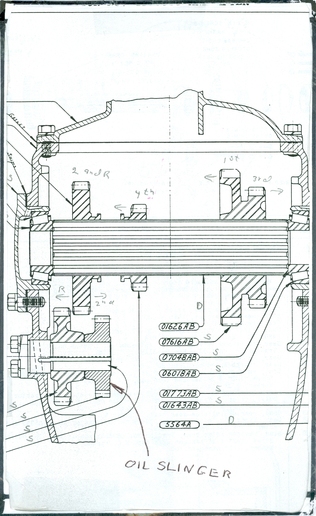

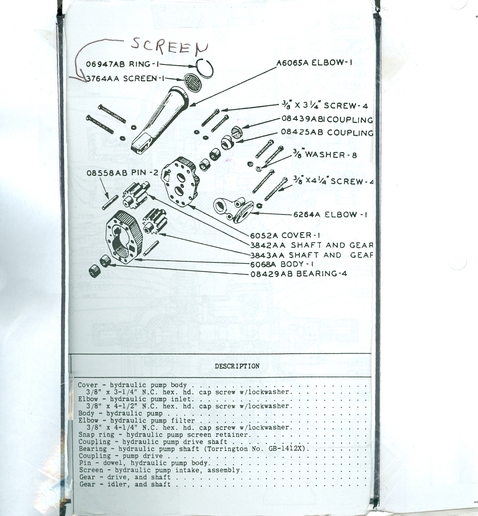

The left side of the oil pan shows a filter screen for the oil pump inlet. I doubt if there is an oil filter so just clean the suction screen. The 52 engine had an oil filter on the right side behind the mag. Sludge collecting in the bottom of the oil pan was natural for the DCs. No doubt you have found out that the 4 side plates on the oil pan are a nice feature for bottom-end work.

The starter gear mechanism apparently works part of the time so a good cleaning will probably fix that problem. Check the armature and brushes while it is apart. New brushes and sandpapering the armature might help a lot.

If you are wishing to sell either the DC or the M to raise some money to fix the other, the M will probably net you 2-4 times the money as the DC. Your DC free is a clue about a DC’s resale value.

You may be lucky and find your DC is in pretty good shape. It seems that step one would be to get the engine running and see how much or little it smokes----- and how much blow-by there might be.

The condition of the cooling system was a challenge on four of my 6 DCs. If yours came to you with antifreeze in it, that is a good sign that internal rust may not be a serious problem to remove. Internally plugged radiators and a freeze crack behind the intake manifold were significant problems for me. Fixing the method for tightening the fan belt was a challenge on several tractors. Just replacing the generator belt is a big challenge on the DC. Most of mine needed rebuilt water pumps and were a challenge to get off.

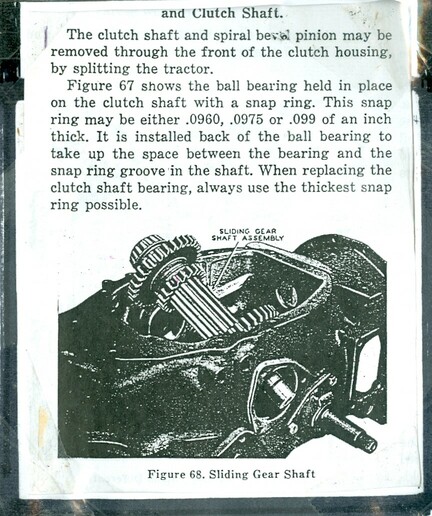

My 53, with a foot clutch, was a problem but none of the hand clutches were a problem. The clutch-brake at the pulley is usually a small challenge to fix.

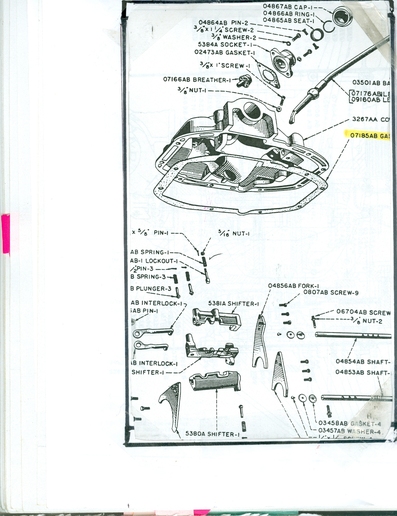

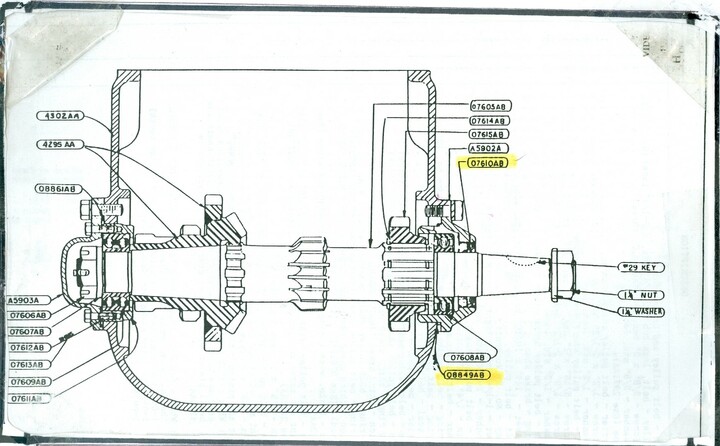

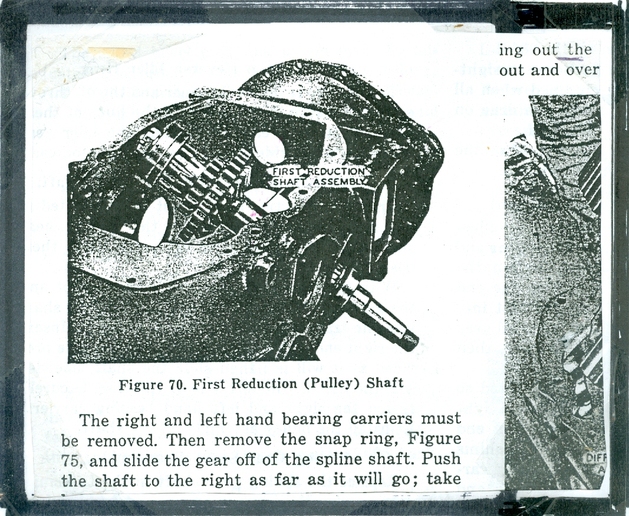

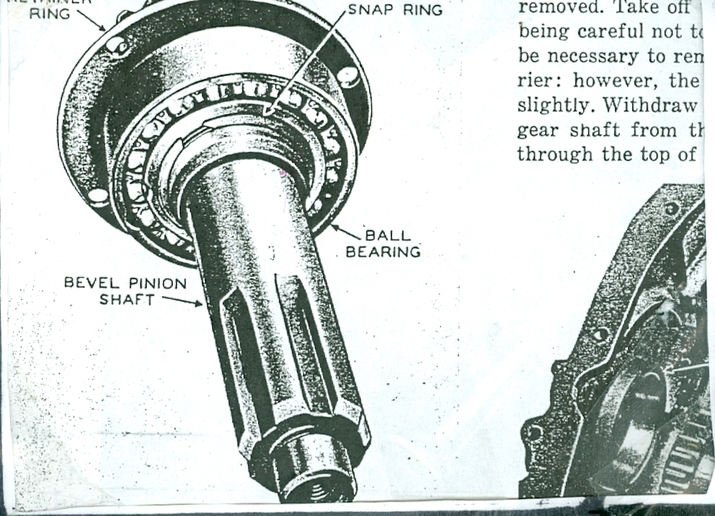

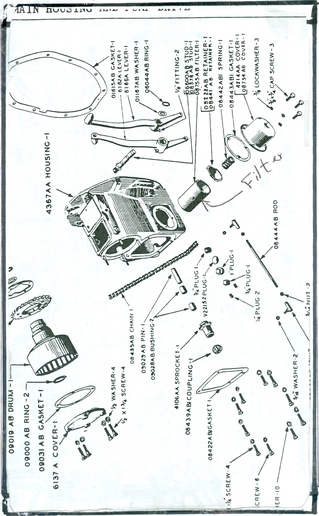

The top of the transmission case comes off pretty easy and this allows a good look at all the gears and chains. Unless one is doing total restoration, liquid gasket sealer works fine especially for the “big” gaskets such as at the main split joint and also the top of the transmission case.

You might be lucky and not need to spend much money to get your DC into fair-to-good condition. Your tires look decent. As mentioned, the upper attach bracket is poorly cobbled and will break the case if much load is applied. Included is a pic of the two choices of correct upper bracket. Sadly, the strong one covers the PTO shaft so no mounted PTO-driven implements.

The swinging drawbar is rinky-dink on the DCs. All mine were worn in the center like that and the rollers were flat-spotted. Your drawbar support is not significantly weak. I choose to clamp all the drawbars tight to the support using the two worn side-holes for the clamp bolts to pass thru.

The final drive chains tend to be low-wear because they run in oil. For high hour tractors, the hole for the drawbar pin tends to be significantly egg-shaped. Also, the upper bearing supporting the steering wheel shaft is likely worn egg-shaped if used a lot.

Your DC looks very clean. Was it power washed sometime back? My DCs came to me with a lot of oily crud in a lot of places.

I hope your DC gets saved from the junk man. LOL Feel free to post any more questions you have along the way. Good luck.