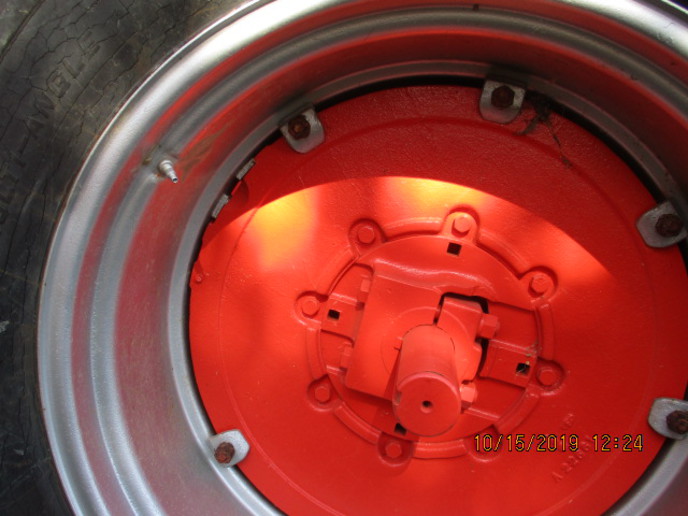

Salt water rusted through around the tire valve. I let it go way too long and then it sat for several years and got worse I ended up cutting out the rust and welding in new metal.

Not an easy task, forming the angle iron. That 2X4 in the bottom of the 2nd photo started out being about 30" long. Notice the charring on one end.

I could not find a replacement 30"x14" double bevel wheel for the CASE. Didn't know what else to do. Any bets on how long it will last ? So far it's been good for about a 100 yards in the past week.

Not an easy task, forming the angle iron. That 2X4 in the bottom of the 2nd photo started out being about 30" long. Notice the charring on one end.

I could not find a replacement 30"x14" double bevel wheel for the CASE. Didn't know what else to do. Any bets on how long it will last ? So far it's been good for about a 100 yards in the past week.