Adirondack case guy

Well-known Member

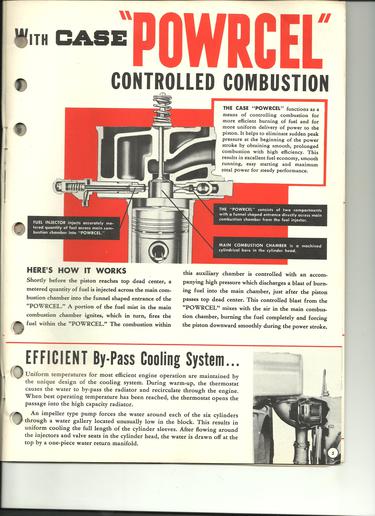

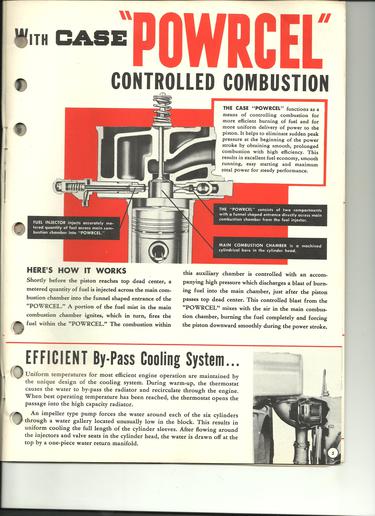

A week or so ago someone posted about coolant leaking into crankcase from heads/pre combustion chambers. I ran across this today in a peice of Case 500 lit. My good friend mEl explained the importance of renewing thes cells when doing an overhaul or any head work. The lit explains how they work, but does not mention the importance of how critical it is to have the two halves of the fuel cell mate together so combustion does not leak between them and erode holes directly into the cooling jacket of the head. The fuel cell is comprised of 3 parts. (1) the threaded cap, which is visible on the outside of the head. (2) the fuel cell cap which forms the outer half of the cell. and (3) the one peice funnel shaped volocity tube and inner half of the pre combustion chamber which is pressed into the head when aligned with a small stablizing pin in the head. If the drawing is unclear to anyone feel free to ask questions and I will elaborate. Sorry for the small print, I made it as big as I could.