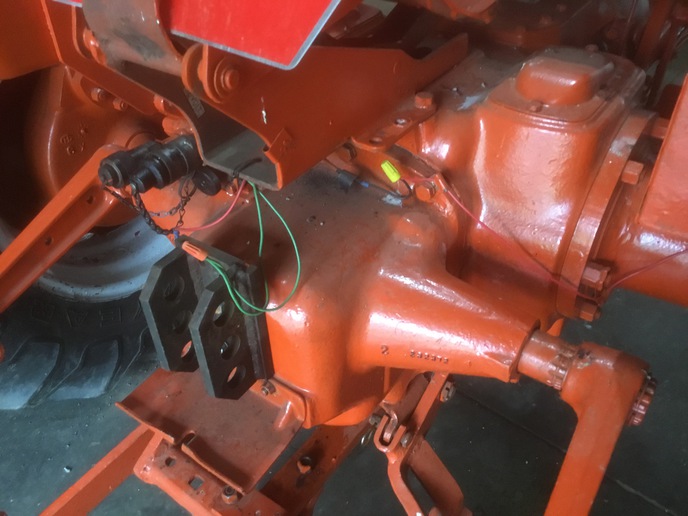

I need some help again I got a D 17 Allis hydraulics three point wouldn?t go up and down so I thought it was low on oil but when I went to check out the

dipstick in that place where it was on other d 17 tractor there was a seal in it so I busted the seal out and filled it up with hydraulic fluid it ran for a while

but it seems like the fluid transfers to the differential hydraulic fluid, now that is over full ,did that seal need to be in there to pressurize the system?

dipstick in that place where it was on other d 17 tractor there was a seal in it so I busted the seal out and filled it up with hydraulic fluid it ran for a while

but it seems like the fluid transfers to the differential hydraulic fluid, now that is over full ,did that seal need to be in there to pressurize the system?