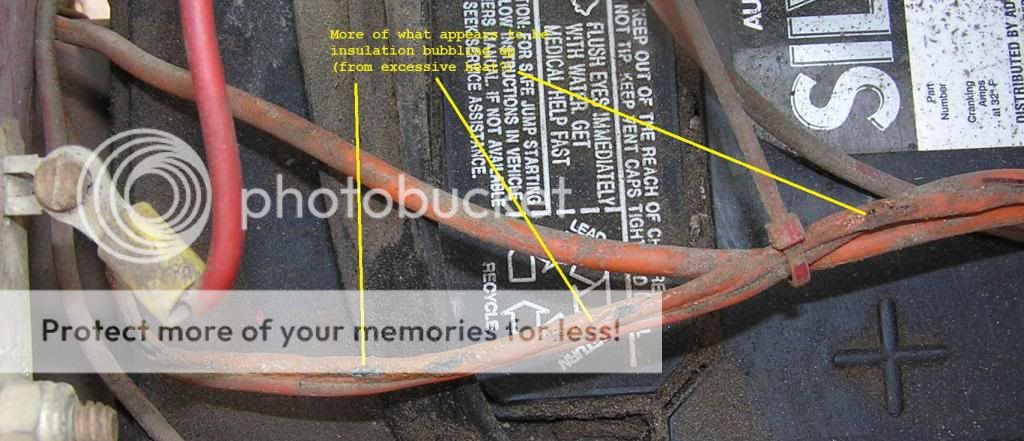

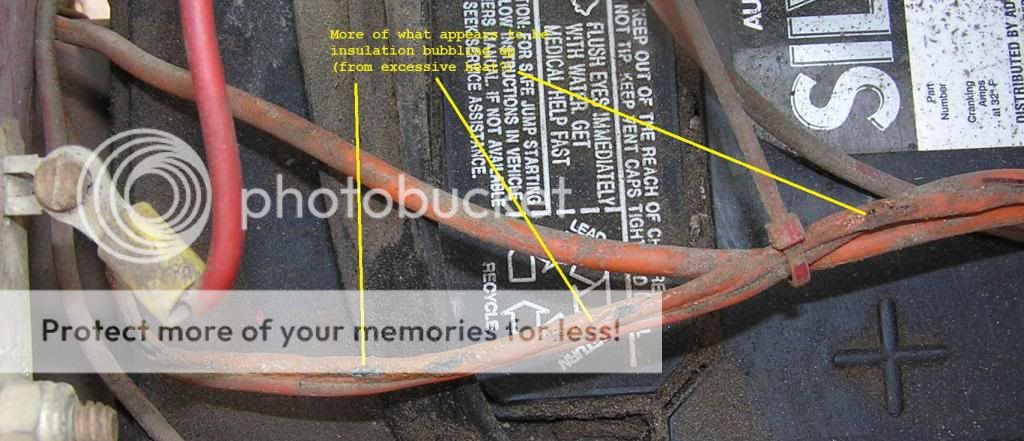

[b:fe28339e2b]As some of you know I bought a 1948 8N about a month ago and I've been trying to fix her up and you guys sure have helped me along. She was converted to 12 V some time ago and I'm getting ready to replace the harness however the wires show some damage I don't understand and I don't want my new harness to suffer the same fate. Can anyone tell me if this looks normal for old wires of if something else is going on that I will need to address?

I'm a complete idiot when it comes to tractors. As a boy we plowed with horses so even a 1948 8n seems really fancy to me lol. A few things came with the tractor, plows shovels a hoist, a scraper, a disc, and the rake pictured below. It doesn't look like any landscaping or hay rake I've ever seen. I sure would like to know what kind of rake that it is if you don't mind helping me to identify it.

Cheers,

Stewart[/b:fe28339e2b][size=18:fe28339e2b][/size:fe28339e2b]

I'm a complete idiot when it comes to tractors. As a boy we plowed with horses so even a 1948 8n seems really fancy to me lol. A few things came with the tractor, plows shovels a hoist, a scraper, a disc, and the rake pictured below. It doesn't look like any landscaping or hay rake I've ever seen. I sure would like to know what kind of rake that it is if you don't mind helping me to identify it.

Cheers,

Stewart[/b:fe28339e2b][size=18:fe28339e2b][/size:fe28339e2b]