Zachary Hoyt

Well-known Member

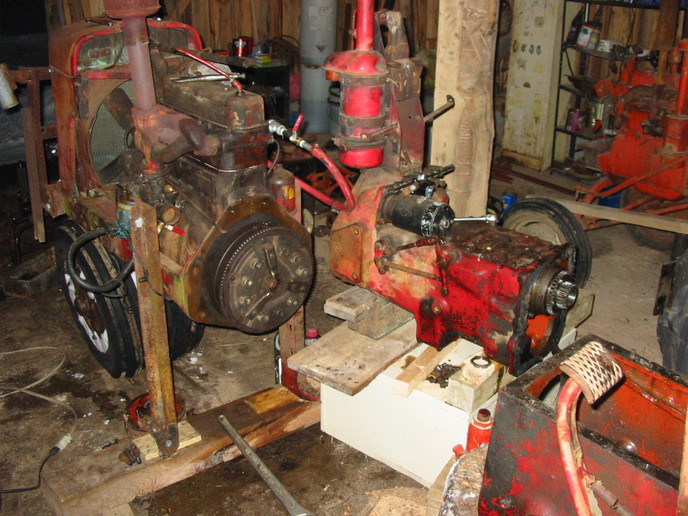

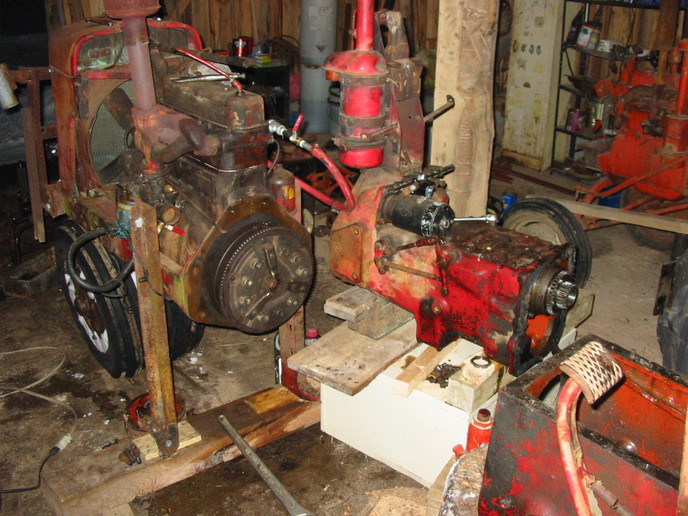

I made some more progress on the 300 today. I put the TA housing on an old copier cart on casters that I had saved and put in the shed with the idea that it would come in handy someday. The pilot bearing had indeed fallen apart as was foretold by various wise sages on this forum. I found one roller by the seasonal disconnect lever, so it must have hopped through the round hole in the front of the transmission housing. The other bearings I have seen so far are all in remarkably good shape, it looks to me like they were put in new by the previous mechanic. I have one axle out now and I found that the outer bearing had been installed with the shield on the inside (toward the center of the tractor), which is backwards of how I thought it was supposed to be, so I plan to turn it around before reassembly. I took one brake apart and found it is in very good shape and the seal looks new. I was going to think about putting H axles in it since I do not want the extra length but I found that the H axles have 16 splines and the 300 have only 14 splines, so that idea goes out the window. Tomorrow I hope to finish the teardown. I am wondering about what is the best liquid to clean the inside of the castings. I was thinking about diesel fuel and an old paint brush but if there is a better way I would like to find out. I also am wondering what to use when I am setting the mesh and backlash on the ring and pinion. My I&T manual says to use "Prussian blue or red lead" and I am wondering if there is some other material that is in use now. Thank you all very much for your patience with my many questions.

Zach

Zach