OliverNate

Member

need to rebuild the water pump for my 1947 oliver 99 4 cyl. and i'm turning up nothing for parts search i've seen some people have machined there pumps to accept a modern seal so if someone has part numbers for that then i have a plan b

the rubber part of the seal has S.C. CO. 19867X (what looks like an upside down SMV) 70 PAT. 2027505 on it there is also a metal sleave part of the seal that the carbon disc rides against its just still in the pump body yet

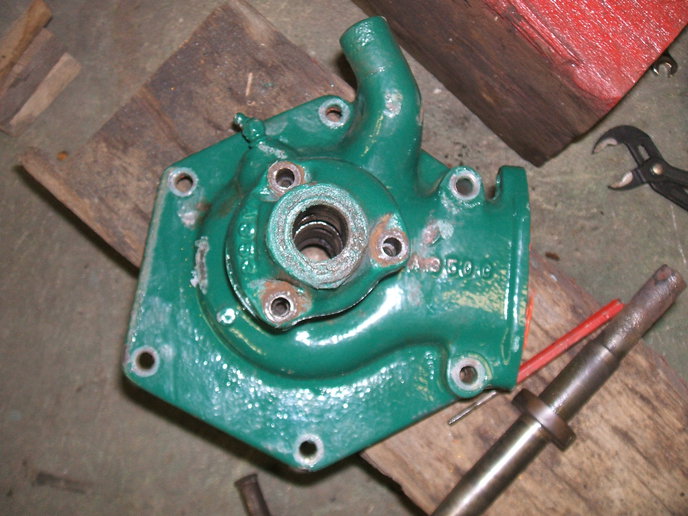

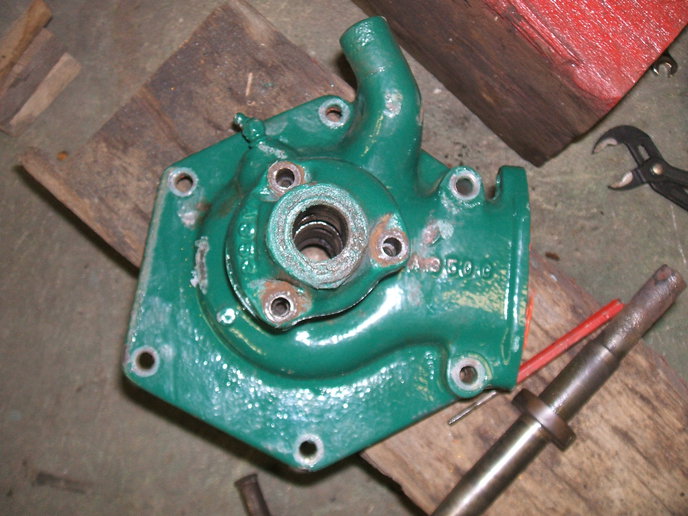

any help is greatly appreciated cause this is the last part of the puzzle I'll include a pretty much finished photo as well

the rubber part of the seal has S.C. CO. 19867X (what looks like an upside down SMV) 70 PAT. 2027505 on it there is also a metal sleave part of the seal that the carbon disc rides against its just still in the pump body yet

any help is greatly appreciated cause this is the last part of the puzzle I'll include a pretty much finished photo as well