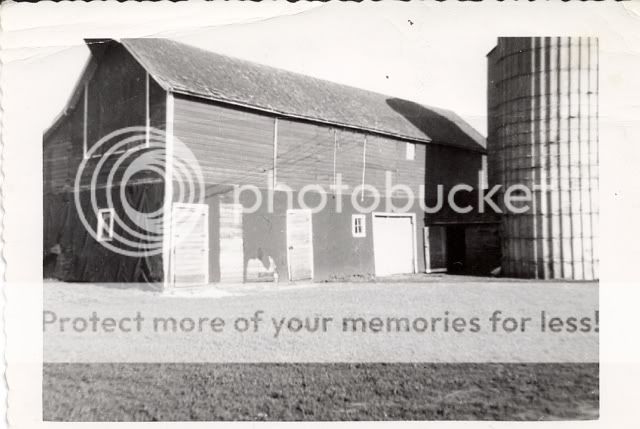

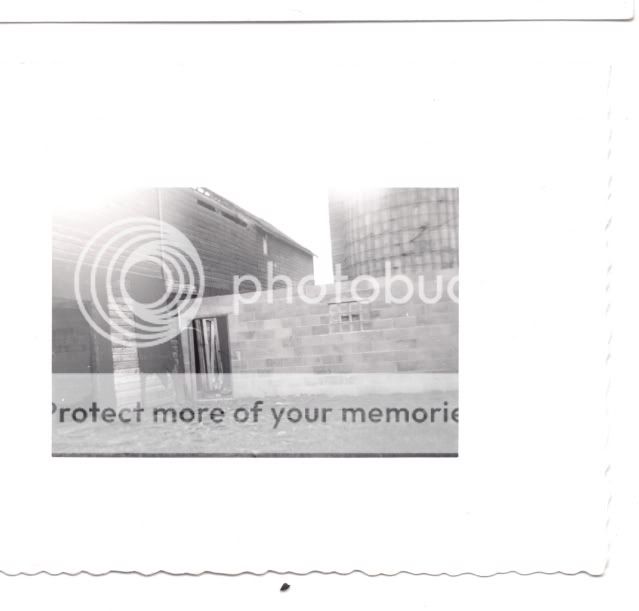

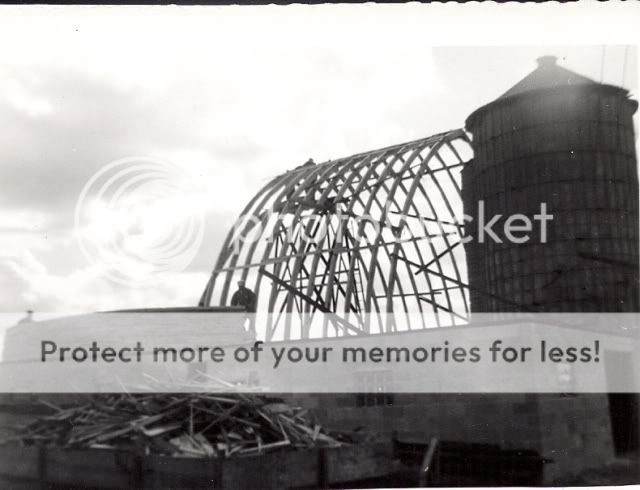

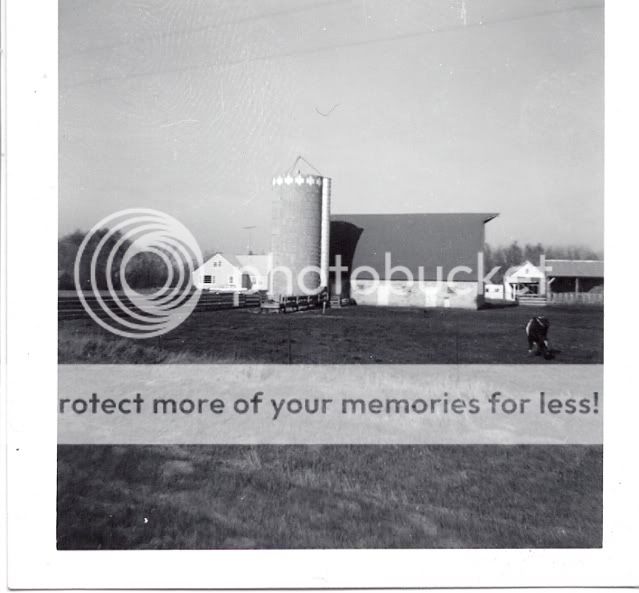

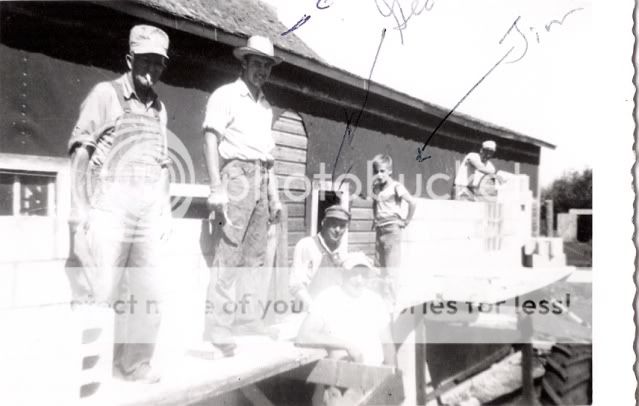

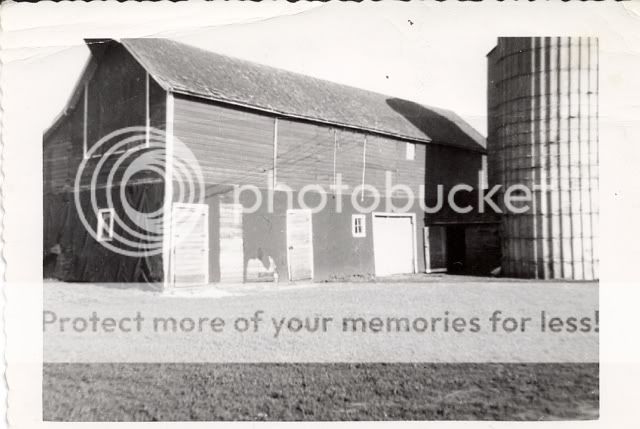

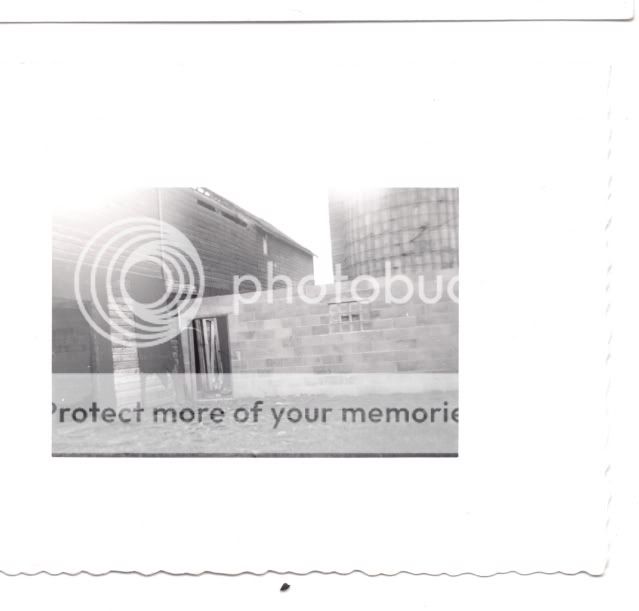

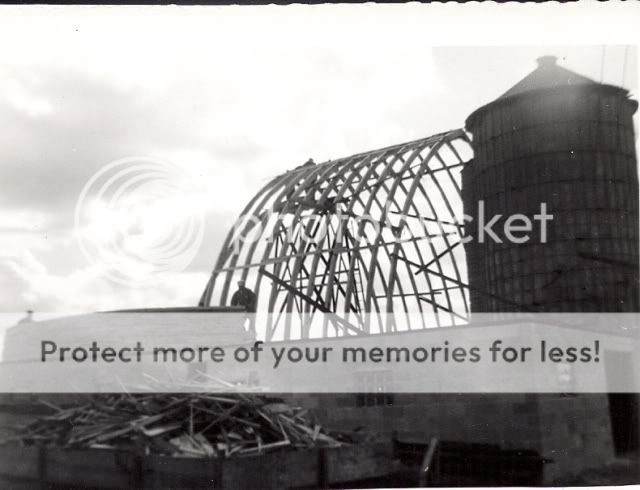

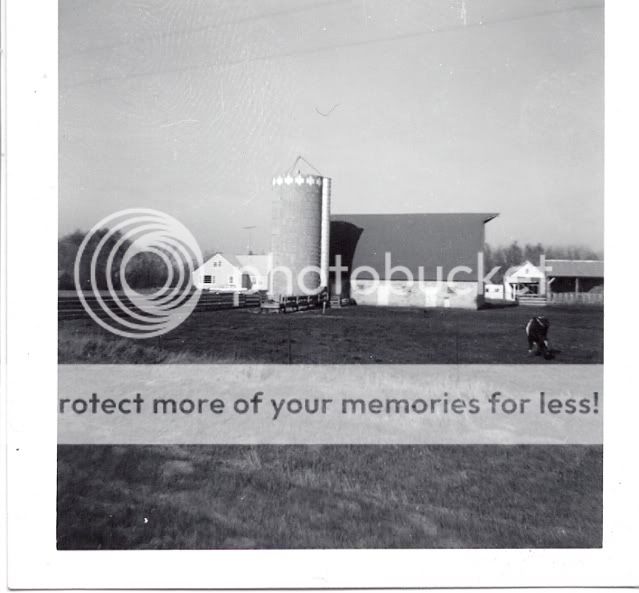

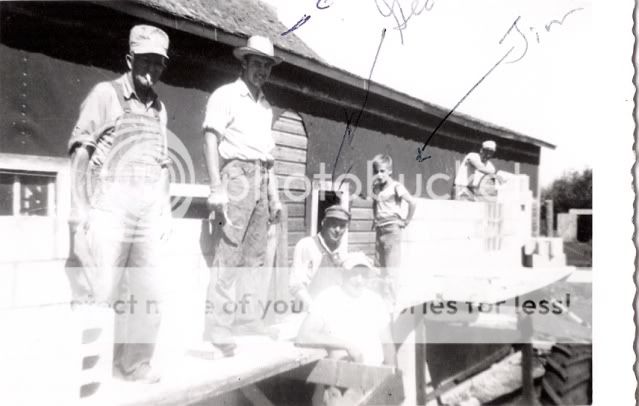

After posting a HM bale loader last week, some folks wanted other vintage pix- these are of our old and new barn in "52. Original barn was built in 3 sections, with 2 different haymow floor levels (foot difference). New block walls were laid through old wooden walls, cows got milked each day during construction, rafters nailed together from homesawed (cottonwood) lumber from our other farm, on the new haymow floor. Silo was lowered (that is a concrete roof) to stay inside the roofline...little frozen silage in winter with bales stacked around it. Gravity water system was fed by 3, 55 gallon tanks welded together. Last pic is the crew. I"m the short one- 8 years old. Brother, Dad, and blocklayers. Tire is "47 WC. (can"t you tell?) Completed barn pic is from early 60s, after the bunk feeder was built. That"s another story- Dad built it with a rubber tire drive system- similar to Ford rear mount cement mixer. Worked ok, except on frosty mornings.