Lou from Wi.

Well-known Member

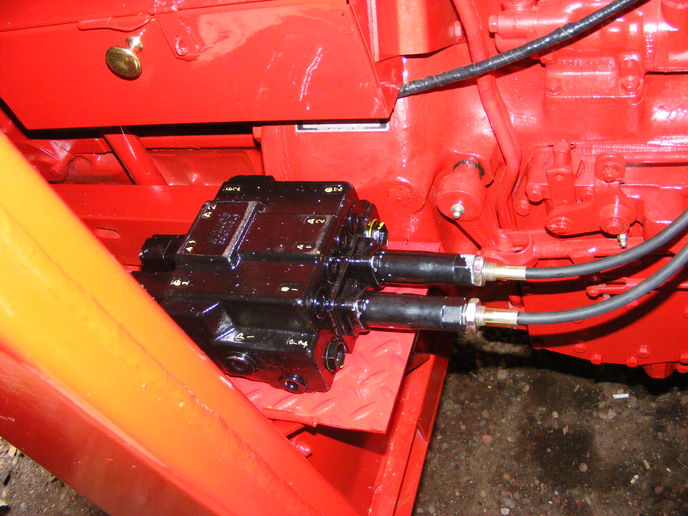

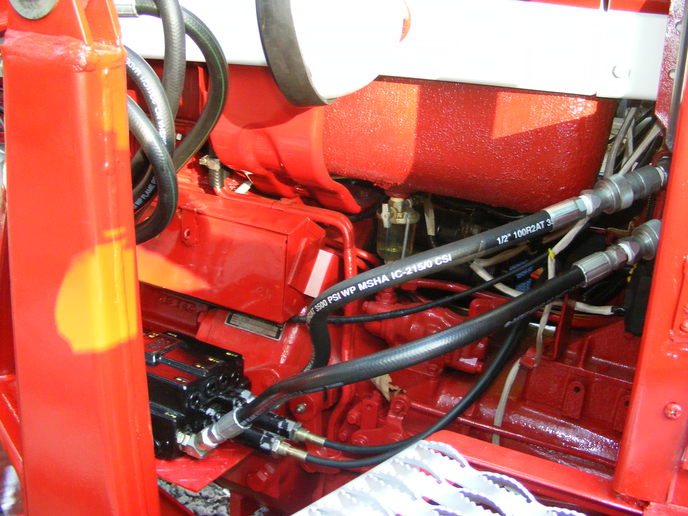

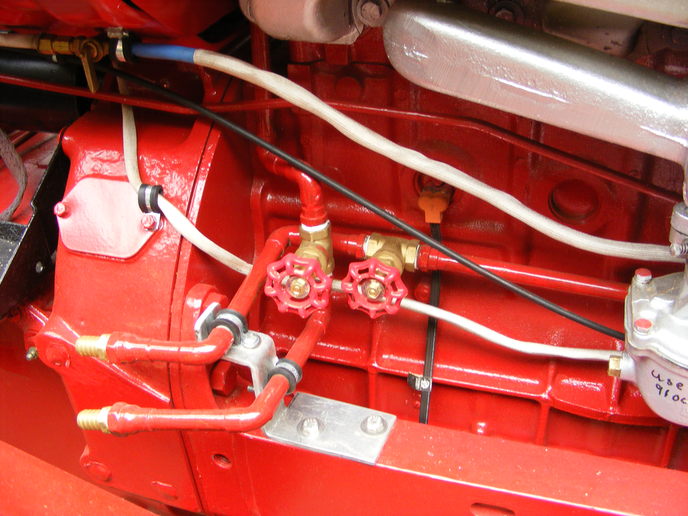

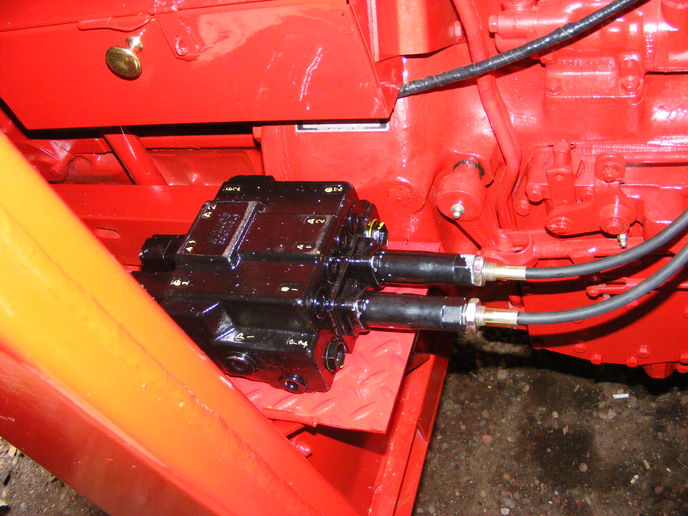

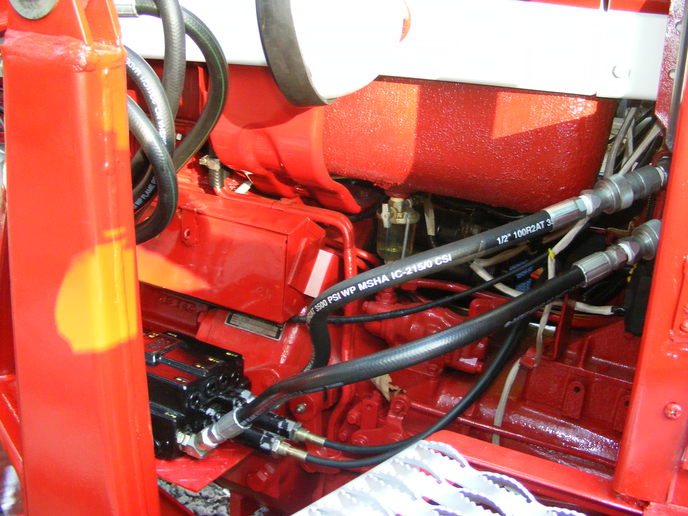

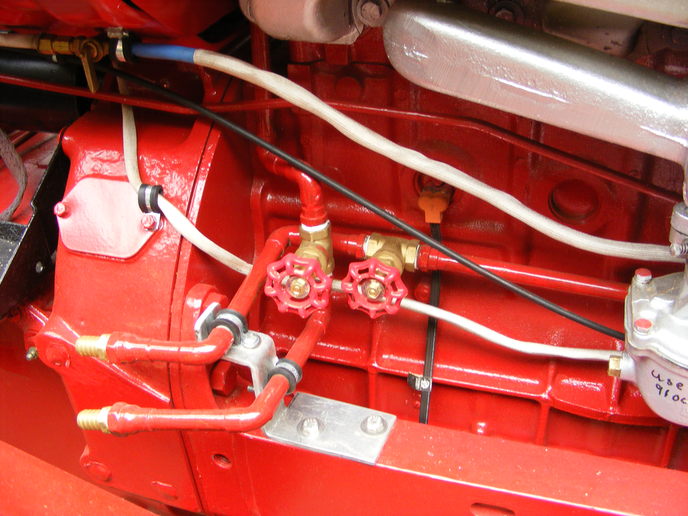

Hey Alan from Neb. Remember you asked where the loader was on the 706.Well here tis/lol. My son finished the Hydraulics today and it works just dandy. His first time in installing ,bending seamless stainless steel tubing .I,in advertanly led you to believe I did it But the truth of the matter is, He done 99/0 of the work in making the tractor what it is today.From manufacturing parts,welding,painting,cab repair. and a host of other items to long here to mention.Next item on the agenda is the sad bucket that the previous owner pushed trees with it. (not the tractor just the bucket.) We made new tangs ,for the schwartz loader,greaseable pins so the wear will be miniscule on the brackets. he and I went all over the country and a couple of states getting the cab,loader rear tire, a rim and tubes. New tires for the front. Ordered the Ss tubing from Ill,bender from Northern tool. fittings from discount Hyd hose company.He did a tremendous job on welding where it was necessary,so the end result is one heck of a fine I.H.706 WITH A LOADER lol Now you don"t have to wonder any longer lol. Here are pictures for you to look at so you know the loader is on and working.

Miss your pictures of your haying etc. ALLAN You are responsible for the heat in the cab,so I won"t freeze my 74 year old ask me no questions off this winter, which by the way,is just over the horizon. Got tire chains just waiting for the ice & snow. Wont be long now as the cat said when he backed into the lawn mower.Thanks for all your advice and help.

LOU

Miss your pictures of your haying etc. ALLAN You are responsible for the heat in the cab,so I won"t freeze my 74 year old ask me no questions off this winter, which by the way,is just over the horizon. Got tire chains just waiting for the ice & snow. Wont be long now as the cat said when he backed into the lawn mower.Thanks for all your advice and help.

LOU