1939farmall

Member

I posted about bringing this little tractor home last week. Today

we started looking it over.

I had some things to do in the shop so son went out and started

cleaning some of the gunk off of it. Hes pretty excited to work

on it!

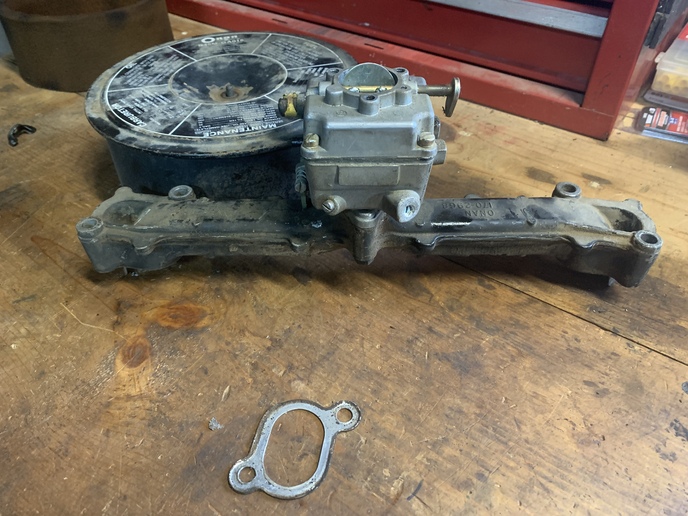

This is an Oman B48M engine we our working with. The story

we have is that it ran when parked, and its been sitting for 10

years. The first thing we noticed is a missing air cleaner screw

right by the throat of the carburetor. Fortunately it appears to

just be missing and didnt make it into the engine. I see a lot of

corrosion on the butterfly in the carb so Im figuring on getting a

gasket set and opening it up. Im sure it needs cleaned.

Son got the air filter off while I took the plugs out.

Heres a picture of them. If you can read plugs please tell me

what there saying!

This has the usual funky wiring a lot of old forgotten machines

end up with. Its also missing the battery ground cable for some

reason. If we can get it running it will get a rewire for sure. It

needs a set of points as well. The engine doesnt appear to have

much compression so we have the cylinders filled with ATF for

now I can see the intake valves moving and the engine turns

free so Im hoping it just has some sticky rings. The carburetor

bolts run up from the bottom of the intake so it was easier to

take the intake and carburetor of as a unit. We found 1 intake

gasket was missing as well. Thats where we stand on day one.

Pretty typical items so far for a machine that has been sitting for

years. On the plus side the gas tank look pretty clean with just

some rusty loose stuff in the bottom, someone added an

electric fuel pump and it still works! And the engine oil and

hydraulic oil look surprisingly good. If you have any tips tricks

thoughts or ideas wed love to hear them. Thanks!

we started looking it over.

I had some things to do in the shop so son went out and started

cleaning some of the gunk off of it. Hes pretty excited to work

on it!

This is an Oman B48M engine we our working with. The story

we have is that it ran when parked, and its been sitting for 10

years. The first thing we noticed is a missing air cleaner screw

right by the throat of the carburetor. Fortunately it appears to

just be missing and didnt make it into the engine. I see a lot of

corrosion on the butterfly in the carb so Im figuring on getting a

gasket set and opening it up. Im sure it needs cleaned.

Son got the air filter off while I took the plugs out.

Heres a picture of them. If you can read plugs please tell me

what there saying!

This has the usual funky wiring a lot of old forgotten machines

end up with. Its also missing the battery ground cable for some

reason. If we can get it running it will get a rewire for sure. It

needs a set of points as well. The engine doesnt appear to have

much compression so we have the cylinders filled with ATF for

now I can see the intake valves moving and the engine turns

free so Im hoping it just has some sticky rings. The carburetor

bolts run up from the bottom of the intake so it was easier to

take the intake and carburetor of as a unit. We found 1 intake

gasket was missing as well. Thats where we stand on day one.

Pretty typical items so far for a machine that has been sitting for

years. On the plus side the gas tank look pretty clean with just

some rusty loose stuff in the bottom, someone added an

electric fuel pump and it still works! And the engine oil and

hydraulic oil look surprisingly good. If you have any tips tricks

thoughts or ideas wed love to hear them. Thanks!