I have a 2002 AWD Astro I bought as an insurance wreck. So, I have no prior history on it. When I first got it all together - I had trouble with it stalling whenever I shifted from reverse to forward (or vice-versa). I pulled the engine-house off and found that the distributor was worn out. Worse I have ever seen. Near 1/4" of side-play on top. Bottom where the drive-gear is was fine. So I put in a new distributor. It started right up and runs great. No more stalling. Van absolutely runs great BUT . . check engine light keeps coming on with code P1345. I already took the distributor out once and did 2nd install putting the engine at TDC and following info in the book. It certainly seemed to go in correctly. This code indicates some sort of timing problem.

At the moment - engine has 187,000 miles and runs like new. No operating complaint. Just this light on. I have no idea if this is a new problem I caused or it was doing it long before I got it.

Two questions.

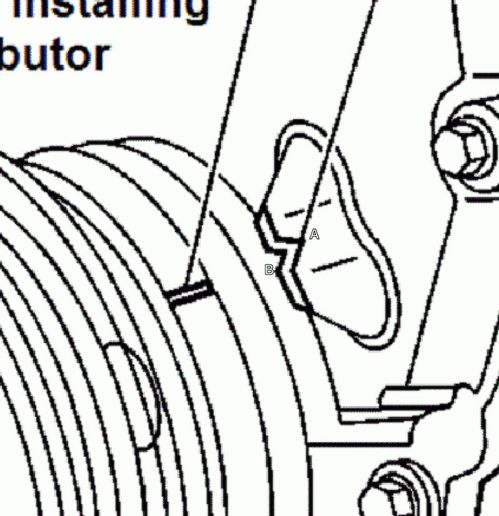

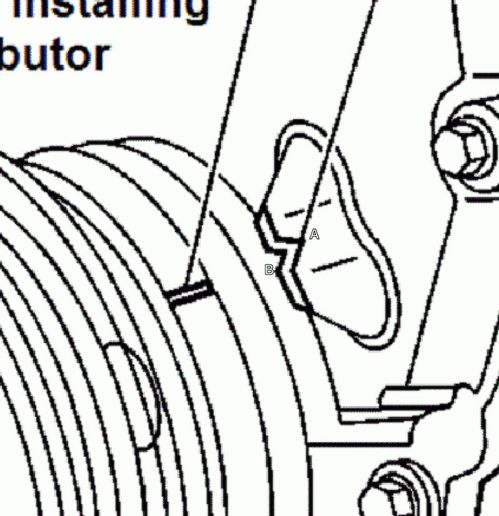

#1 -I am not sure how the crank-pulley indicator works to show TDC. Note the image I posted. I am not sure if the line on the pulley needs to point to the middle of the VEE I marked "A", or to an edge next to the VEE I marked "B."

#2 Has anyone ever verified a good running 4.3 engine with enough timing chain wear to keep throwing this code?

At the moment - engine has 187,000 miles and runs like new. No operating complaint. Just this light on. I have no idea if this is a new problem I caused or it was doing it long before I got it.

Two questions.

#1 -I am not sure how the crank-pulley indicator works to show TDC. Note the image I posted. I am not sure if the line on the pulley needs to point to the middle of the VEE I marked "A", or to an edge next to the VEE I marked "B."

#2 Has anyone ever verified a good running 4.3 engine with enough timing chain wear to keep throwing this code?