Hey guys, I'm working on my Sunflower field

cultivator. It is an older one, has wings

and 4 lift cylinders. The depth stop valve

was not internal to the cylinder, it was an

external device mounted inline before the

first lift cylinder. It had gotten rusty

and ruined it before I got it, and leaked a

lot of oil, so I had just bypassed it for

the time being. Parts for the depth stop

are no longer available, and a newer style

depth stop valve is about $1500 from

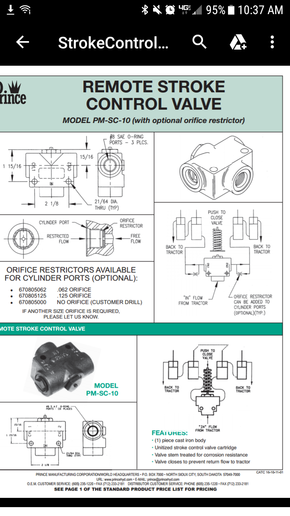

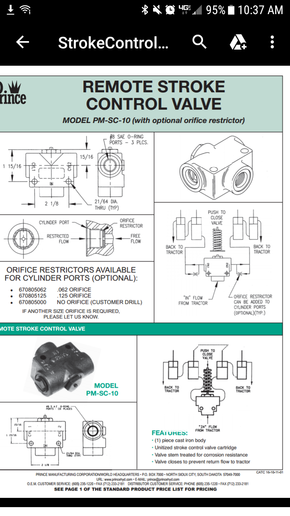

Sunflower. So I found this Parker cylinder

stroke control valve for $60. I think it

will work just fine, but I have a question

on my plumbing. All of the cylinders are

plumbed in a loop essentially. The one hyd

line runs into the bottom of the first

cylinder for lift, then comes out the top

of the same cylinder and goes into the

bottom of the next cylinder. And so on,

until it ends with the last hose coming out

of the top of the last cylinder going back

to the tractor. Could I use this valve

inline at the inlet to the first cylinder

of the group like the last one was, or will

I have to split it between the first 2 lift

cylinders as shown? Here's a picture of the

valve I plan to use. Thanks guys

Ross

cultivator. It is an older one, has wings

and 4 lift cylinders. The depth stop valve

was not internal to the cylinder, it was an

external device mounted inline before the

first lift cylinder. It had gotten rusty

and ruined it before I got it, and leaked a

lot of oil, so I had just bypassed it for

the time being. Parts for the depth stop

are no longer available, and a newer style

depth stop valve is about $1500 from

Sunflower. So I found this Parker cylinder

stroke control valve for $60. I think it

will work just fine, but I have a question

on my plumbing. All of the cylinders are

plumbed in a loop essentially. The one hyd

line runs into the bottom of the first

cylinder for lift, then comes out the top

of the same cylinder and goes into the

bottom of the next cylinder. And so on,

until it ends with the last hose coming out

of the top of the last cylinder going back

to the tractor. Could I use this valve

inline at the inlet to the first cylinder

of the group like the last one was, or will

I have to split it between the first 2 lift

cylinders as shown? Here's a picture of the

valve I plan to use. Thanks guys

Ross