Christopher S.

Member

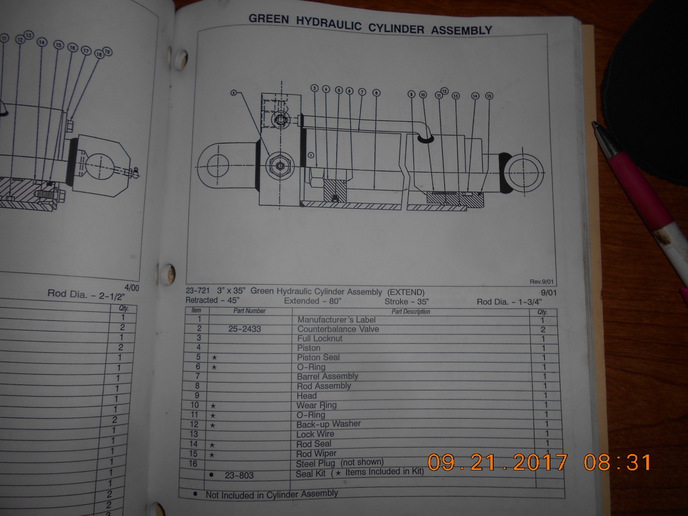

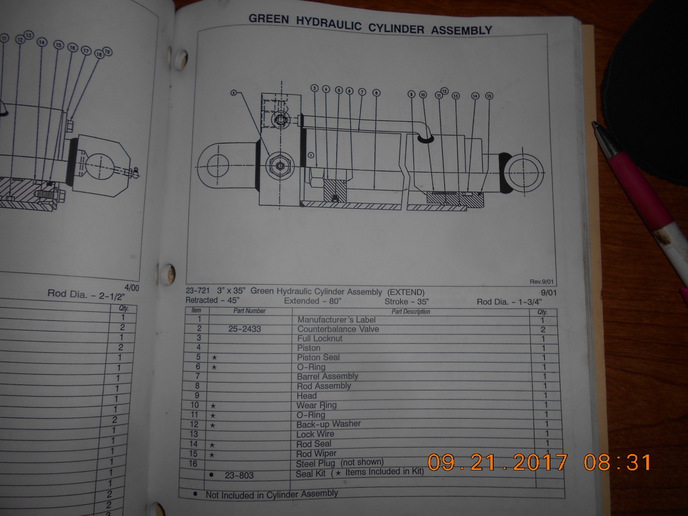

Good Evening Gentlemen, the hooklift assembly on our Dads roll-off truck needed to be re-shimmed. He mentioned that the jib extension cylinder was creeping a little bit on him during road travel between locations. We decided to repack the cylinder during the shimming procedure since 1/2 the disassembly would be done at this point. Fast Forward...we got the hydraulic cylinder out of the truck and on the work bench. We removed the retaining wire and began un-threading the gland nut with minimal force. We achieved about 1/8" of separation between the gland nut and cylinder body. The gland nut will spin either direction but we can't get it on or off. What are we missing or doing wrong? Is there a piece of the retainer wire broken off in its groove?

Thanks fellas!

Thanks fellas!