Lou from Wi.

Well-known Member

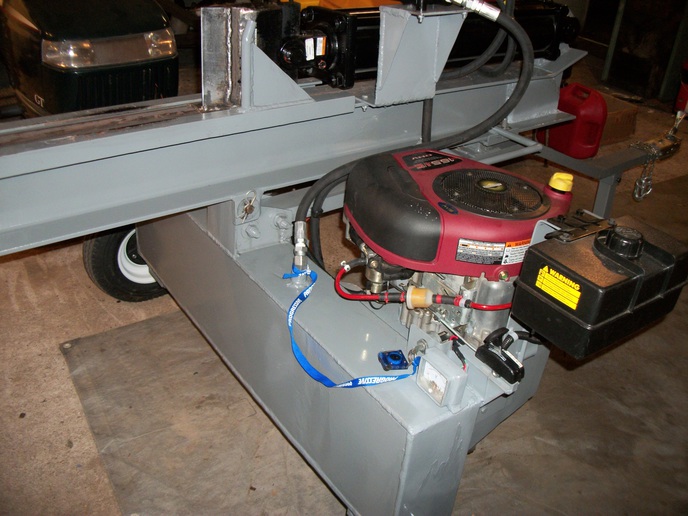

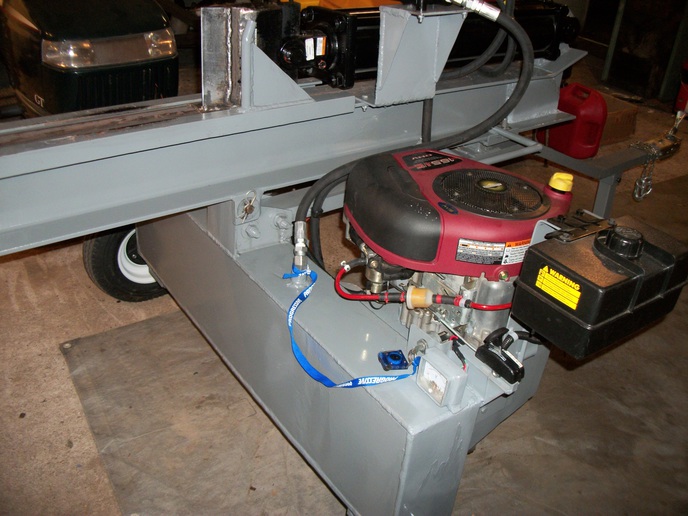

My way of thinking is it's best to have two of every tool be it hand tools or machinery (like log splitters)which we have built from scratch )with the exception of engines, pump, hydraulic valves, cylinders,axles, tires, oil, steel, these items we had to buy.

Now the problem----.Daughter paid for the 16.5 B&S used.Got the splitter built ,even installed on the tank, an volt meter so we could see what the charge rate is on the battery(Battery start engine) as my Son is getting tired of pulling the starter rope on the 8 hp.

Daughters wood(13+loggers cord)is cut & blocked and we took the newest splitter down to the pile and started splitting.

Now the unit started spitting Black oil out of the engine.

Son and I had it running (short time)before engaging wood so-yesterday was a tear down and found the head gasket blown through on two places.Today was clean up head & O.H Valve chamber and replaced head gasket, exhaust gasket O.H valve cover gasket, which we made at $6.38 each ( 3) Spares if needed plus one factory one.

Got the engine back together today,runs great with NO OIL

LEAKS!!

Run it 1/2 hr and tomorrow back to the wood pile and if it starts leaking, out comes the 8 hp first picture.(first one built ) and use it . Winter season is FAST aproaching , no time to waste.

Sure like the electric start.Got to keep warm and way to old to hand split lol.

Regards Lou & Son.

Now the problem----.Daughter paid for the 16.5 B&S used.Got the splitter built ,even installed on the tank, an volt meter so we could see what the charge rate is on the battery(Battery start engine) as my Son is getting tired of pulling the starter rope on the 8 hp.

Daughters wood(13+loggers cord)is cut & blocked and we took the newest splitter down to the pile and started splitting.

Now the unit started spitting Black oil out of the engine.

Son and I had it running (short time)before engaging wood so-yesterday was a tear down and found the head gasket blown through on two places.Today was clean up head & O.H Valve chamber and replaced head gasket, exhaust gasket O.H valve cover gasket, which we made at $6.38 each ( 3) Spares if needed plus one factory one.

Got the engine back together today,runs great with NO OIL

LEAKS!!

Run it 1/2 hr and tomorrow back to the wood pile and if it starts leaking, out comes the 8 hp first picture.(first one built ) and use it . Winter season is FAST aproaching , no time to waste.

Sure like the electric start.Got to keep warm and way to old to hand split lol.

Regards Lou & Son.