Zach Scherf

Member

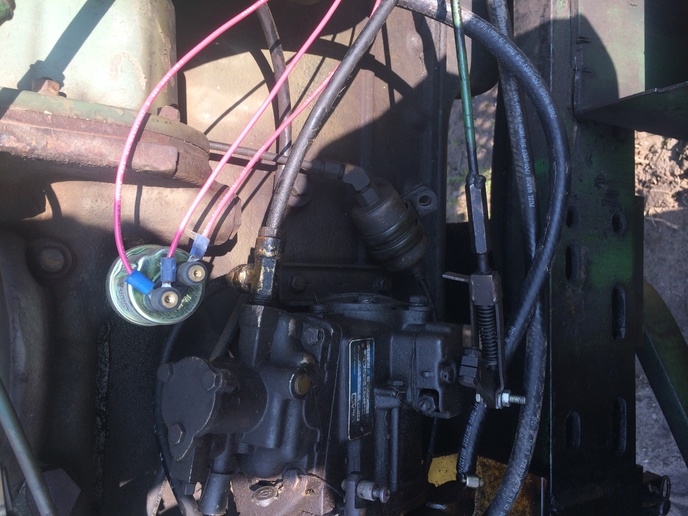

I have a white 2-150 tractor that i swapped a 465ldt multifuel engine into last year. It saw limited use, but this year i got all of the bugs worked out. The tractor idles great, runs

great at any rpm when under no load. This year i tried to use it for fieldwork and ran into a problem. It runs excellent with no load, but when going down the road with an

implement, or when using in the field, it will randomly seem to bog and then stop completely. Sometimes it will start up immediately and go for a little longer, other times it will

not. I have a small inline electric fuel pump that feeds the fuel from the tank to the filter that then feeds the injection pump. I have changed all of the rubber fuel lines and

stopped all leaks thinking perhaps i was sucking air. I then thought that the electric pump may have been messing up, but then realized it is always still working when the tractor

dies. I believe i have a problem in the injection pump. I changed the fuel filters last year and also dont believe there is any kind of restriction in the tank. I know it is a fuel

problem. The model of the injection pump is Ambac psb 6A-90EH-5337A3. Im a decent mechanic but have no experience tearing into a pump like this and honestly dont have a

clue what to look for. Hoping for some guidance or advice as i really dont want to spend another 1000 to have the pump rebuilt.

great at any rpm when under no load. This year i tried to use it for fieldwork and ran into a problem. It runs excellent with no load, but when going down the road with an

implement, or when using in the field, it will randomly seem to bog and then stop completely. Sometimes it will start up immediately and go for a little longer, other times it will

not. I have a small inline electric fuel pump that feeds the fuel from the tank to the filter that then feeds the injection pump. I have changed all of the rubber fuel lines and

stopped all leaks thinking perhaps i was sucking air. I then thought that the electric pump may have been messing up, but then realized it is always still working when the tractor

dies. I believe i have a problem in the injection pump. I changed the fuel filters last year and also dont believe there is any kind of restriction in the tank. I know it is a fuel

problem. The model of the injection pump is Ambac psb 6A-90EH-5337A3. Im a decent mechanic but have no experience tearing into a pump like this and honestly dont have a

clue what to look for. Hoping for some guidance or advice as i really dont want to spend another 1000 to have the pump rebuilt.