Skybow, good questions I can tell you are thinking this through and sincerely trying but NO its NOT quite correct (YES Billy Bob and Bubba, I know, save your breath, don't have a calf, you did it that way for years and never had a problem, it will "work")

Here's the deal: As I understand your question you are feeding a SUB PANEL in your garage that's fed from your homes Main Panel and want BOTH 120 and 240 (2 legs of 120) available in the garage Right?????

Some of your plan is correct some is NOT

1) "I would run a separate ground wire to a copper rod thru the garage floor into the earth below."

NO You need to wire the sub panels "Equipment Ground Buss" FROM the Main Panel Ground Buss TO the Sub Panel where it bonds to the Sub Panel's Equipment Ground Buss which is separate and isolated from the subs Neutral Buss. If you wire the subs Equipment Ground Buss down to a Ground Rod instead, that would be wayyyyyyyyyyyyyy to much resistance to conduct fault current back to the main panel. The purpose of the Equipment GroundING Conductor is to provide a dedicated low impedance return current path ONLY FOR FAULT CURRENT. The earth isn't a good conductor, there would be a lot of resistance from that rod driven into the ground back to the Main Panel where Ground and Neutral Busses are bonded together and Neutral is bonded to a ground rod there. That's why you need a low resistance wire conductor, NOT rely on earth (higher resistance) to conduct fault current.

"..... keeping the ground and neutral bus separated in the garage panel"

YES in the garage Sub Panel the Equipment Ground Buss and Neutral Buss are separate and isolated HOWEVER the Subs Ground Buss needs to be wired to the Main Panels Ground Buss NOTTTTTTTTTTTT to a rod driven into the earth.

WHAT YOU NEED TO RUN FROM THE MAIN TO SUB IS FOUR NOTTTTTTTTTTTTTT THREE WIRES

Two Hot Ungrounded Conductors L1 & L2,,,,,,,,,,,,,One Neutral Grounded Conductor (wires to sub panels Neutral Buss ONLY) ,,,,,,,,,,,,One Equipment Grounding Conductor (Wires to Sub Panels Ground Buss ONLY). The Equipment Ground Buss in the Sub Panel wires back to the Main Panels Ground Buss NOT to a ground rod.

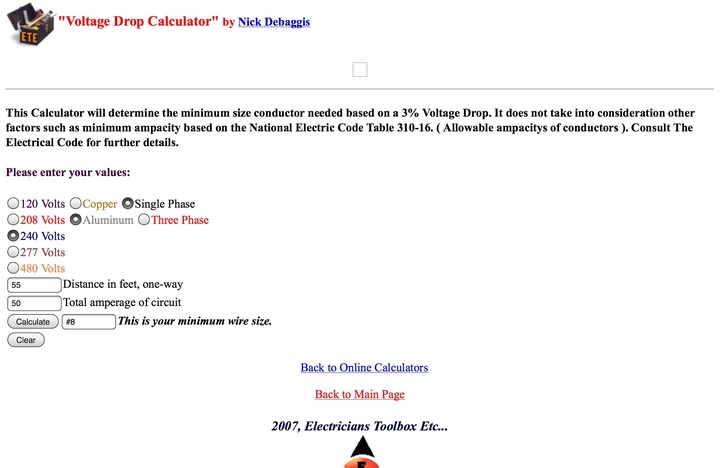

According to the chart I looked at, No. 6 THWN or THHN Aluminum Conductor wire at 75 Degrees has a rated ampacity of 50 amps so you would protect it with a 2 Pole 50 amp circuit breaker in the Main Panel where it serves the Sub Panel (use anti oxidant grease/coating and correct torque).

All you have to do is run that fourth Ground Wire out to the Sub Panel (in addition to the three you mentioned) and it will be correct.

As usual Electrical or Legal questions draw more responses (some from professional electricians some not, but all well intentioned) then most any other topics, so see what other lay as well as professional opinions have to offer and do as you please. I'm long retired as a distribution design engineer and rusty on the latest codes so no warranty. CHECK WITH LOCAL AUTHORITY (if applicable in your jurisdiction) AND YOUR UTILITY PROVIDER, NOTTTTTTTTTT ME. Some posters may agree with me, some may have more or less to offer, ITS YOUR HOME AND YOUR RISK AND YOUR DECISION NOT OURS.

John T