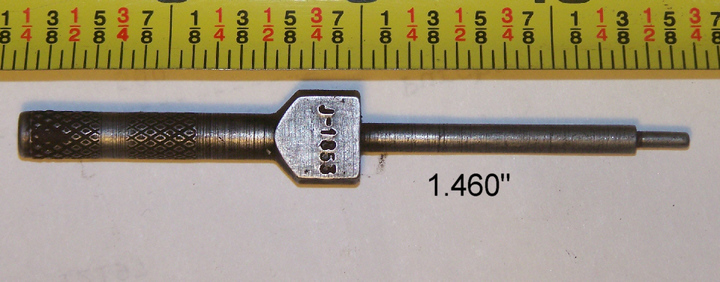

Does anybody happen to have the injector height setting tool laying around? The 3-53 i have is the type that utilizes the tool that drops down in a small hole on what i guess ill call the body of the injector. The service manual lists out all the possible height settings, but my question is, is that height setting based on going from the bottom of the valve to the top of the retainer, like the book says to set it too?

I will go ahead and order the tool online. I found that snapon has them online for like 120 bucks, but since its sunday i was hoping somebody could give me some insight on this so i could at least try this to see if i could ball park it. It would be real nice to actually hear it run before i make any more decisions.

On a side note, this is in a loader that got as a non running unit. The previous "mechanic" put in new injectors, but failed to clean off the 2 pounds of rat poop on the head prior to doing this.

Thanks!

I will go ahead and order the tool online. I found that snapon has them online for like 120 bucks, but since its sunday i was hoping somebody could give me some insight on this so i could at least try this to see if i could ball park it. It would be real nice to actually hear it run before i make any more decisions.

On a side note, this is in a loader that got as a non running unit. The previous "mechanic" put in new injectors, but failed to clean off the 2 pounds of rat poop on the head prior to doing this.

Thanks!