Geo-TH,In

Well-known Member

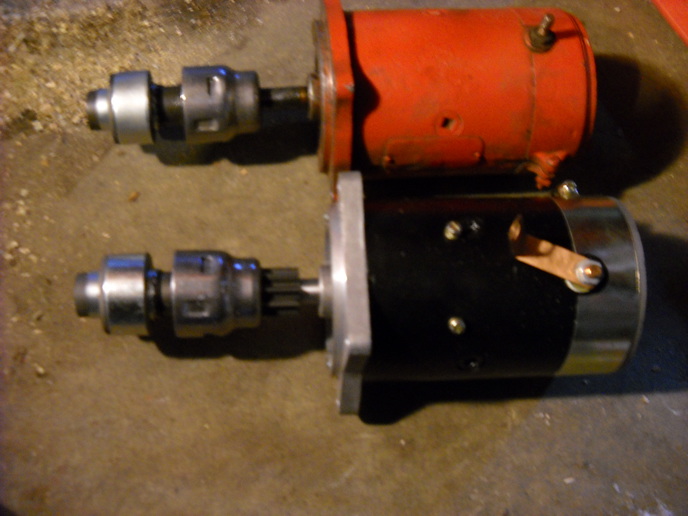

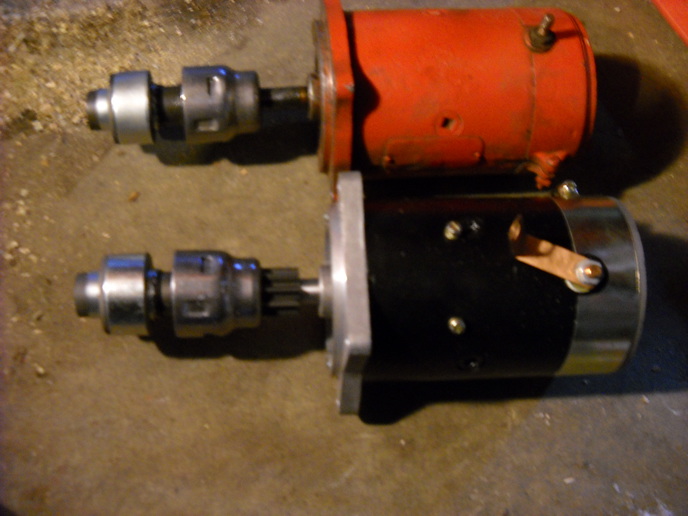

My Jubilee was converted to 12v before I got it. In 5 years had two starter drives go bad. Last one things sounded real bad. I ordered a 12v starter from YT, $147 shipping included. Installed it today and just like I thought one tooth on starter ring is more than half missing. Not sheared off, Chipped off.

Many will be many say they have gone for years using a 6v starter on 12v. Some even said I was making too much out of this.

I will say you are playing Russian rulet. Do you want to spend $147 on a nice sounding starter from YT, shipped in 2 days, or do you want to split the tractor and replace the starter ring?

Many will also say OHM'S LAW doesn't apply here. If you double the voltage, don't change the resistance, you will also double the current. Twice the voltage, twice the current, 4 time the power. I don't care if you don't think the 6 volt starter is producing 4 times the power. The starter drive can slam the teeth on flywheel and chip them. The pic is proof.

Do yourself a favor and buy a 12v starter. And if you recommend using a 6v starter, please warn them it's possible to chip a tooth off.

Many will be many say they have gone for years using a 6v starter on 12v. Some even said I was making too much out of this.

I will say you are playing Russian rulet. Do you want to spend $147 on a nice sounding starter from YT, shipped in 2 days, or do you want to split the tractor and replace the starter ring?

Many will also say OHM'S LAW doesn't apply here. If you double the voltage, don't change the resistance, you will also double the current. Twice the voltage, twice the current, 4 time the power. I don't care if you don't think the 6 volt starter is producing 4 times the power. The starter drive can slam the teeth on flywheel and chip them. The pic is proof.

Do yourself a favor and buy a 12v starter. And if you recommend using a 6v starter, please warn them it's possible to chip a tooth off.