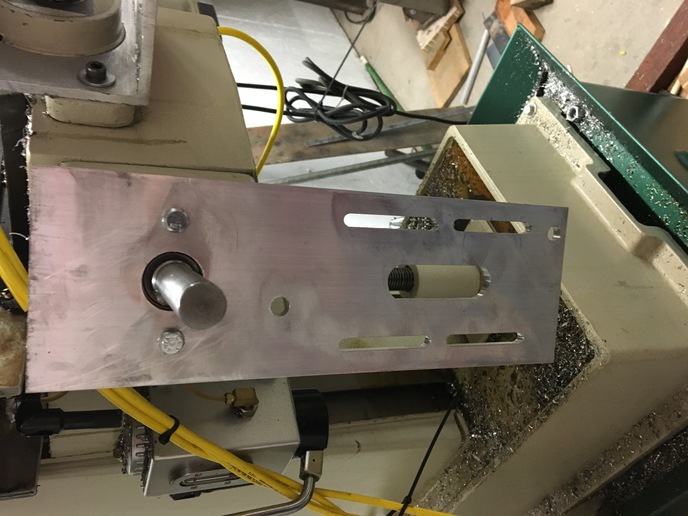

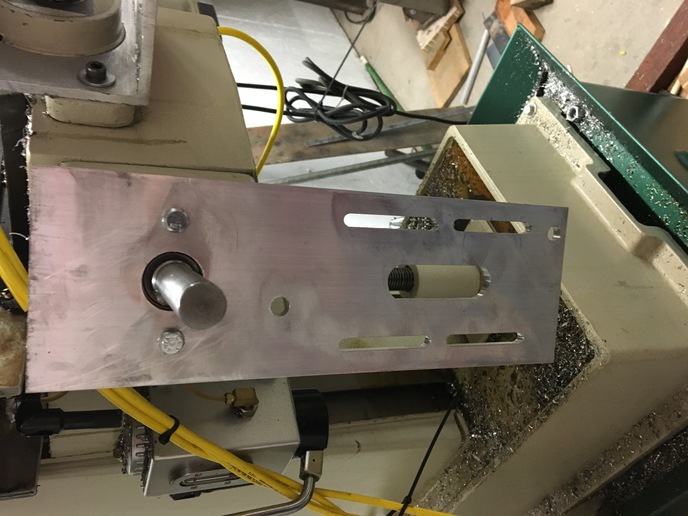

I got the bracket made for the Z axis stepper motor today, picture is sideways, but attached. I wrote the program one line at a time in G code, but did some things manually like cutting the slots. I punched the holes on either end with CNC and hand grooved.

The suggested speeds for the 1/4 mill bit on the aluminum worked well, I used 10 IPM and 1600 RPM on the 3 flute, I did break one, but that was my fault simulating the Z axis. I am anxious to get that working, as it is a PIA to do that while the other axis are moving in CNC.

I blew up another stepper driver today disconnecting a stepper motor while hot. I knew they cannot be disconnected while moving, but I guess they cannot be unplugged while stationary due to the brake current. I need to use the motors to move the bed, and not use the cranks, as I unplug the motors so they do not fight me while doing manual operations. That has been a hundred dollar lesson, so might just leave the cranks off when done.

The suggested speeds for the 1/4 mill bit on the aluminum worked well, I used 10 IPM and 1600 RPM on the 3 flute, I did break one, but that was my fault simulating the Z axis. I am anxious to get that working, as it is a PIA to do that while the other axis are moving in CNC.

I blew up another stepper driver today disconnecting a stepper motor while hot. I knew they cannot be disconnected while moving, but I guess they cannot be unplugged while stationary due to the brake current. I need to use the motors to move the bed, and not use the cranks, as I unplug the motors so they do not fight me while doing manual operations. That has been a hundred dollar lesson, so might just leave the cranks off when done.