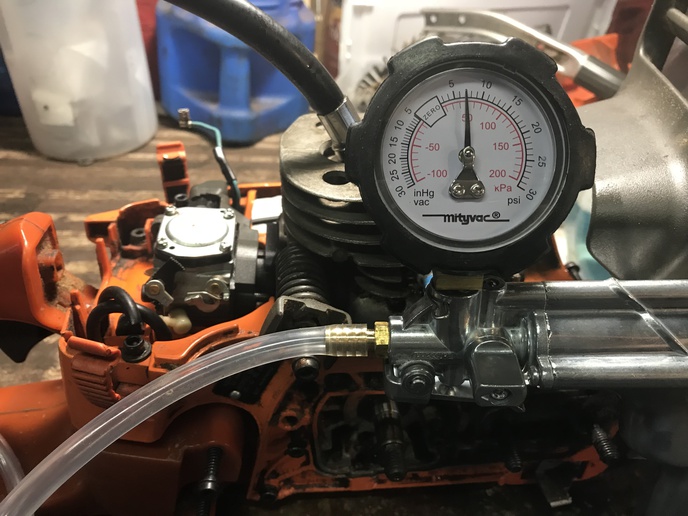

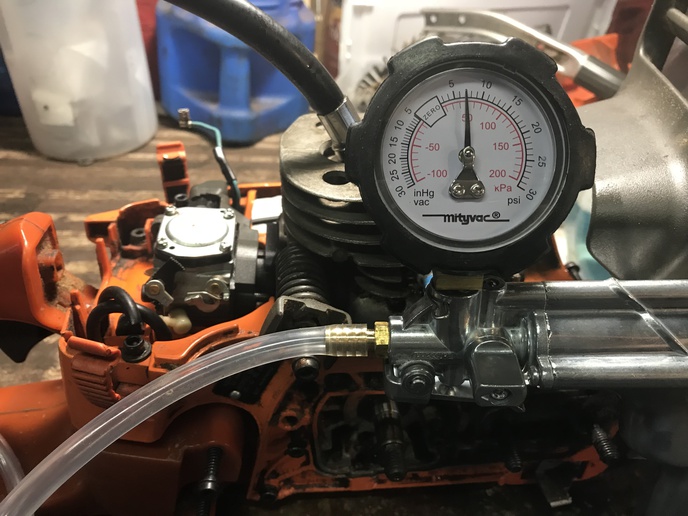

Earlier I posted about an issue I was having with a Husqvarna 359 that wanted to rev up while at idle then die. I was advised that my problem may be leaking crank shaft seals or a bad carb so I decided to do a pressure test on the case and the carb. I tested the crank case with my new Mityvac 8500 and much to my surprise it held seven pounds for over 15 minutes! I also puled 7 inHG vacuum and was able to hold that as well. I then tested the carb with the same 7 lbs of pressure and it held as well. This is my first try at testing in this manner so I'm hoping I'm doing it right. I sealed off the muffler and intake, then attached the pressure line to the sparkie plug hole with the piston in BTC. I had pressure to both the intake and the muffler ports. So now I'm at a loss, what am I missing? Any Thoughts?

Thanks Dan

Thanks Dan