john in la

Well-known Member

I have a steel front door that I need to replace the wood jamb, brickmold, threshold because it is rotting out at the bottom after years of abuse.

Looking at the lumber yard I see that I have a few options.

I can replace it with another wood jamb/brickmold that would be no problem to install.

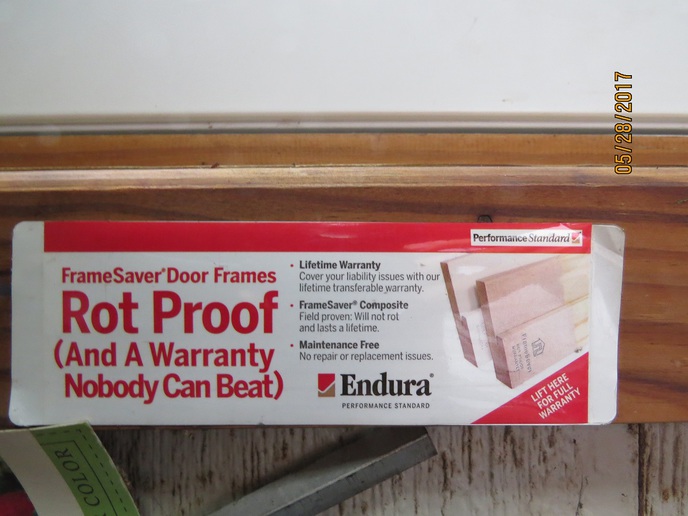

Or I can replace it with a composite jamb/brickmold that is made out of PVC.

Does anyone have any experience installing this composite material.

Being PVC I assume you will have to pre drill all nail holes.

My biggest sticking point is mortising the hinges in.

Do not see the old school hammer and chisel doing this job on PVC.

Assume you would need to router the hinges in so that means you also need the aligning jig.

Looking at the lumber yard I see that I have a few options.

I can replace it with another wood jamb/brickmold that would be no problem to install.

Or I can replace it with a composite jamb/brickmold that is made out of PVC.

Does anyone have any experience installing this composite material.

Being PVC I assume you will have to pre drill all nail holes.

My biggest sticking point is mortising the hinges in.

Do not see the old school hammer and chisel doing this job on PVC.

Assume you would need to router the hinges in so that means you also need the aligning jig.