Oregon Tractor Jack

Member

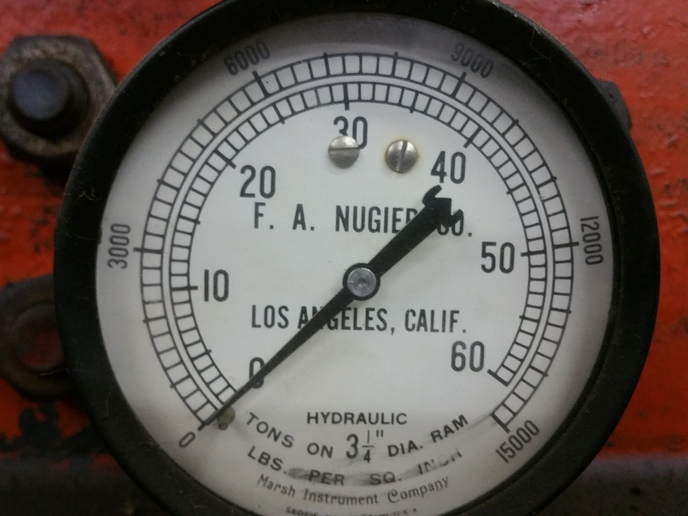

Okay, I'm stumped. I bought a 50 ton air over oil shop press and the pressure/force gauge is kaput. I called the manufacturer to price a replacement and they wanted a CRAZY price for one. Like $400 crazy. I figured I don't really need a gauge the reads in tons and that psi is quite workable. I measured the bore of the cylinder, figured out the area, divided the area into the tons/pounds of force and figured I needed an 8000psi gauge. I found 10k psi one at the local hydraulic fitting shop for $12.50. Great! I put it on the press and it doesn't move off zero. The gauge is plumbed directly above the cylinder. I even went back to the shop and exchanged it thinking the first one was defective. The second one doesn't budge either. What am I over looking?

OTJ

OTJ