I decided to use Linux CNC.

I have decided to use steppers with linear feedback on the bed, which will make them act like servo's.

There are two fronts, getting the computer running, and mounting the mechanical parts on the mill.

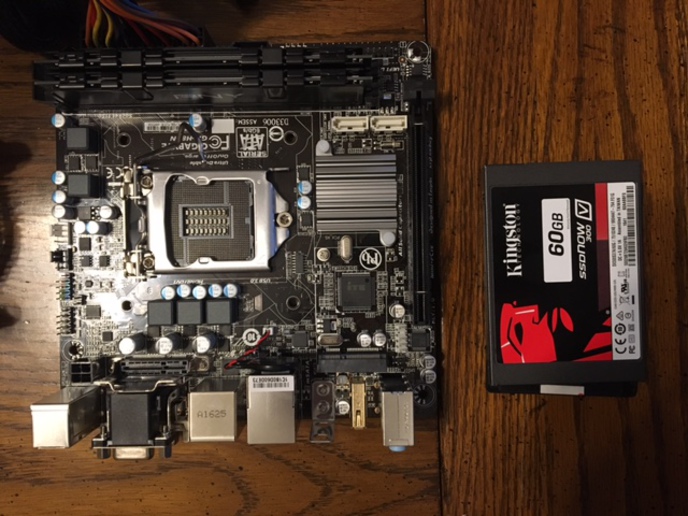

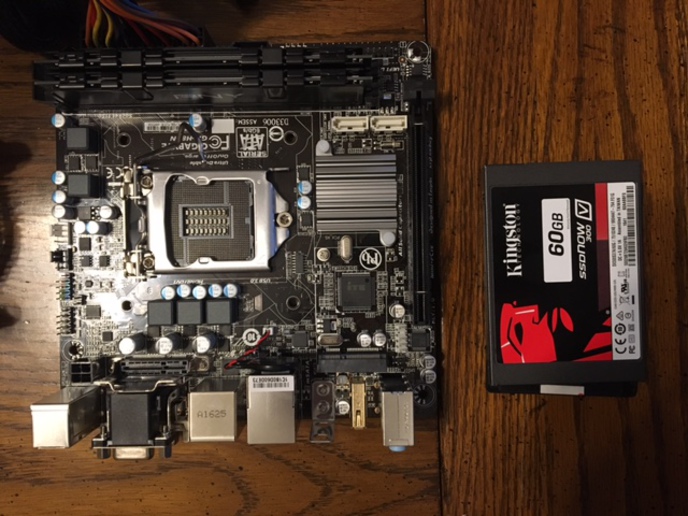

Here is picture of little motherboard I got, did not know there are multiple pinouts of Intel I3 CPU's so have to get another CPU.

I have designed the motor mounts in Solidworks, they are 4x4 by 1/4 wall aluminum. I will post the layouts of them, once I figure out how to do that. I ordered a rotary vice for the mill so I could bore the holes, but the box came empty. I exchanging emails with the vendor trying to figure out where it went.

I have decided to use steppers with linear feedback on the bed, which will make them act like servo's.

There are two fronts, getting the computer running, and mounting the mechanical parts on the mill.

Here is picture of little motherboard I got, did not know there are multiple pinouts of Intel I3 CPU's so have to get another CPU.

I have designed the motor mounts in Solidworks, they are 4x4 by 1/4 wall aluminum. I will post the layouts of them, once I figure out how to do that. I ordered a rotary vice for the mill so I could bore the holes, but the box came empty. I exchanging emails with the vendor trying to figure out where it went.