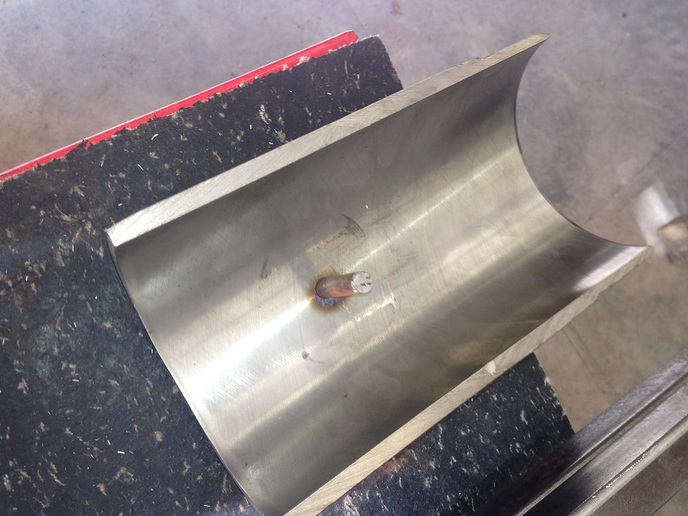

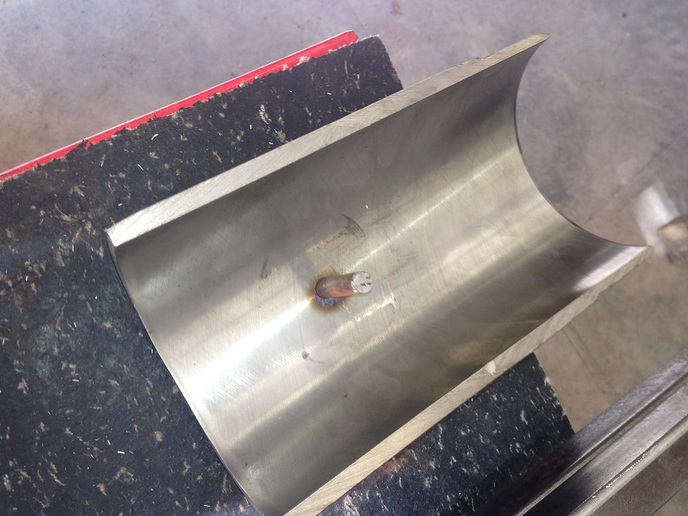

I was faced with a New Idea Super Sheller Auger Tube that had come in contact with the trailing wagon both denting and flattening the tube. Based on some comments I saw on another forum I can up with this tool to push the dents and flat out of the auger tube. The tool consists of a scissors jack, a JD 4440 cylinder liner, and some 1" square tubing to position the tool in the tube and operate the scissors jack. Note the pin I welded in each cylinder half to index it to the hole in the scissors jack top and bottom, I think the pictures tell the rest. If anyone wants more information please let me know. Paul