jon f mn

Well-known Member

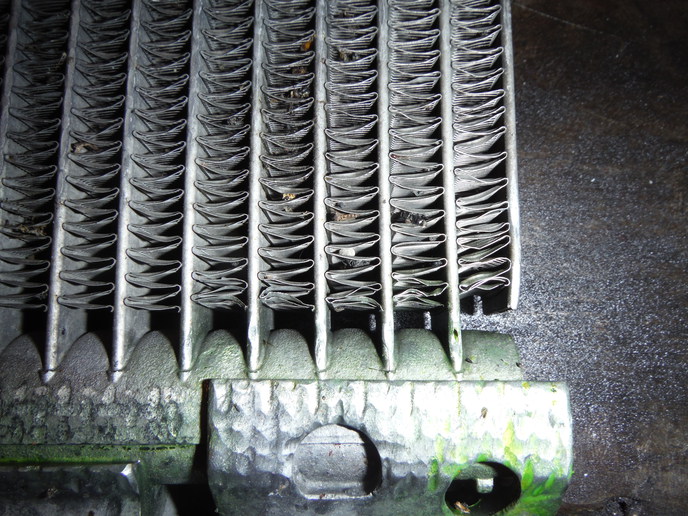

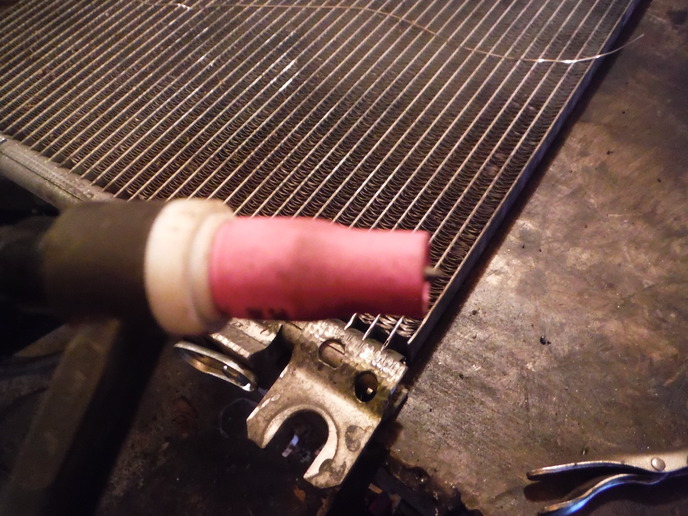

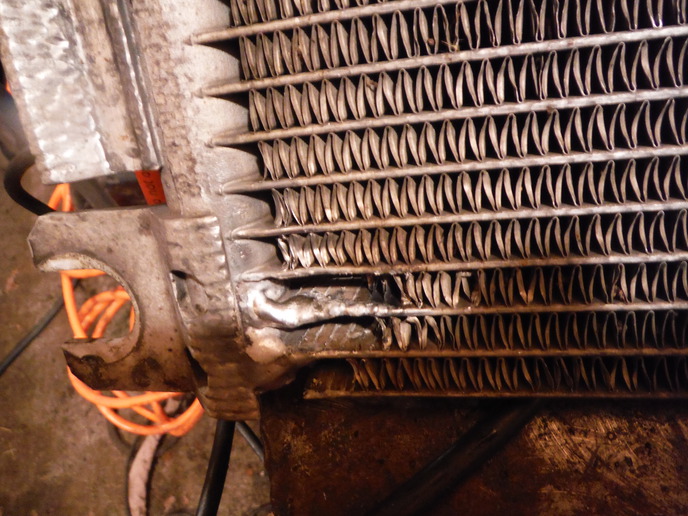

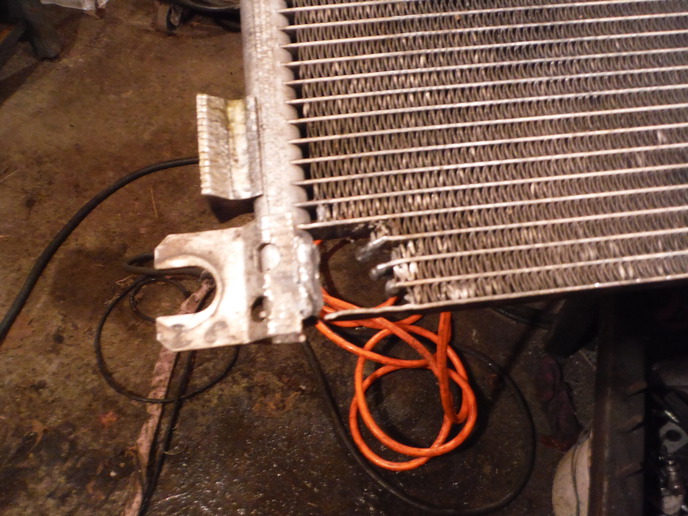

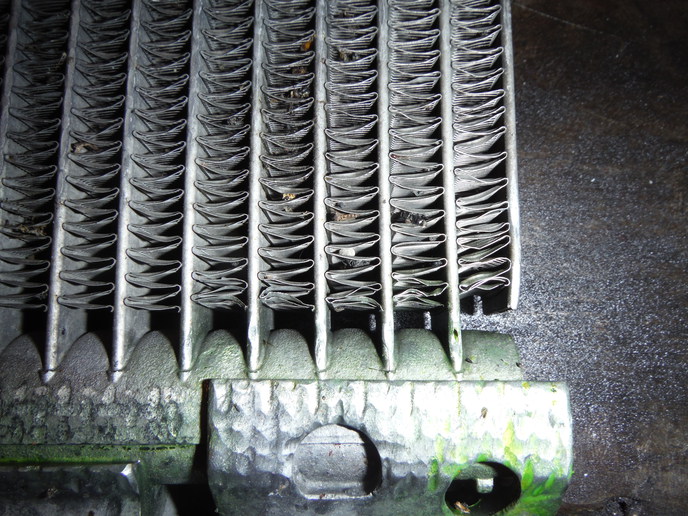

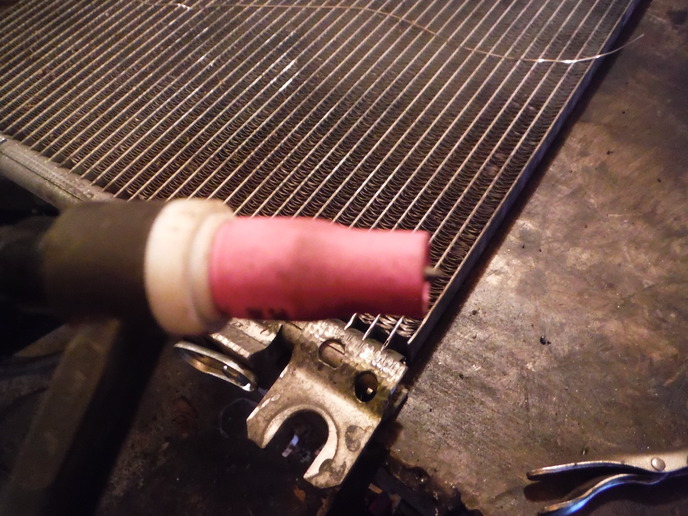

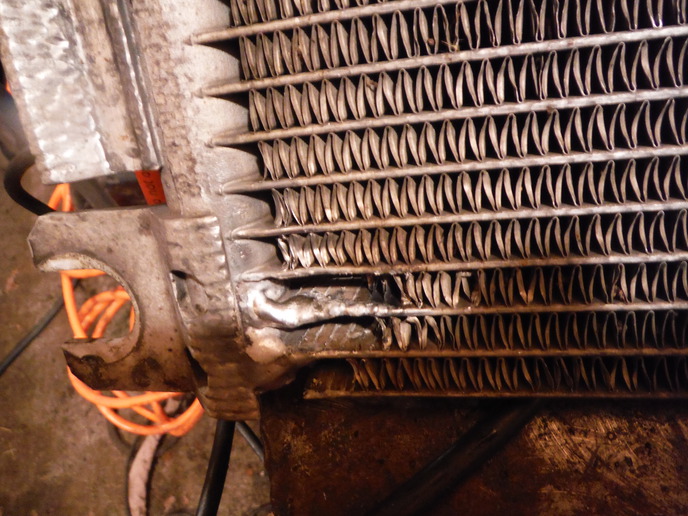

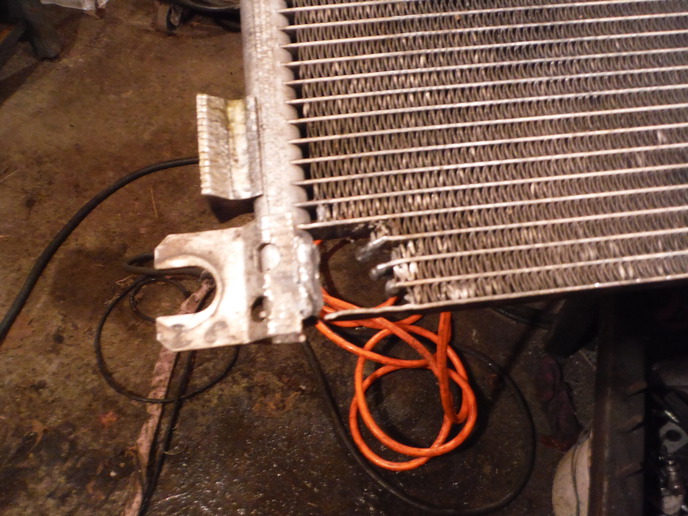

When my truck got hit a while back part of the damage was the condenser. The mechanic told me they couldn't be fixed, so naturally I had to find out. Was home today and it's raining so I gave it a shot. The first 2 pics are of what I started with. You can see the hole and cracks in the first 3 runs. The third is the tungsten and cup I used, they are a bit too big for this job, but are all I had. The next pic is my first attempt. There was some oil inside that was coming out and giving me trouble. I didn't have room to get down between enough to get a seal tho. The last pic shows what I ended up doing. I had to cut the leakers and shorten them so I could get them sealed. I got them sealed, but had a lot of trouble chasing pin holes from the oil inside cooking out through the welds. 3 less runs won't likely cause problems, but you couldn't get by with this for someone else. This was just something I did for fun and to see if I could. I got it sealed and will keep it for a spare, but it's not really a good repair. I used to do these all the time back when, but I'm out of practice now and the new ones are thinner and more poorly made so fixing them is just not realistic. Plus for about $225.00 you get a new one and if I was going to get paid to fix it it would cost $100.00 or more, so it's just not cost effective.